Proposal of brushless motor

Nowadays, the need for automation is accelerating from production equipment to everyday life. Motors are indispensable for automation. On the other hand, efforts to realize carbon neutrality are in full swing worldwide, and there is an urgent need to respond to energy saving and high efficiency in each field.

Meanwhile, high-efficiency and compact brushless motors (PM motors / circuits) are attracting attention as key parts for automation. Oriental Motor's brushless motors have been used in many devices and equipment. Introducing the strengths of our motors that contribute to solving problems.

Brushless Motor Application examples Line up

What is a brushless motor?

A brushless motor is a speed control motor that uses a circuit (driver / inverter) to control a motor that uses a permanent magnet for the rotor. It is characterized by high efficiency and is significantly smaller than the induction motor used for power, which contributes to energy saving and resource saving.

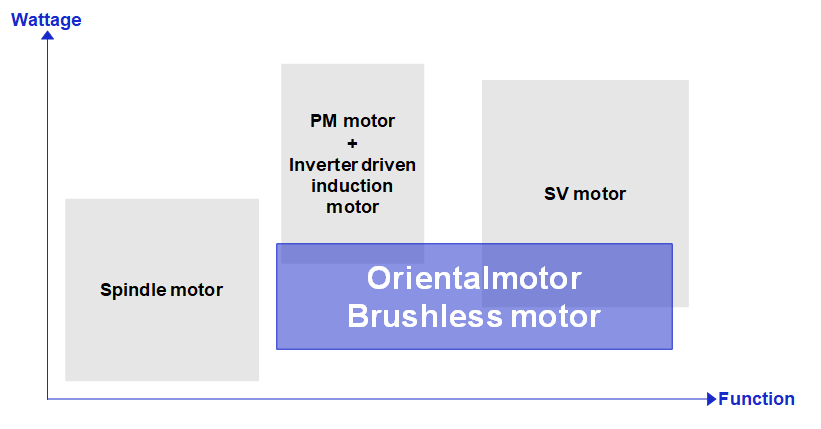

Generally speaking, brushless motors and PM motors are often thought of as large motors such as spindle motors and motors for car power units, but Oriental Motors handles intermediate sizes from 15W to 400W. It is widely used in various automatic machines including production equipment because of its high speed stability due to the optimum control by the hall sensor mounted on the motor and the dedicated circuit (driver).

History of brushless motor development

Oriental Motor started developing brushless motors in the early 1980s. Initially, it was an outer rotor type with a DC power input, but while responding to market demands, we have developed an AC power input and an inner rotor type. Since around 2000, it has become possible to control torque and position, and it has evolved to performance comparable to servo motors. In recent years, both motors and drivers have become smaller and are often used to drive conveyors and transfer robots. We have always maintained a stable supply and development that matches the market needs, and have been supported by the market for many years.

Product strengths

Energy-saving and resource-saving design that contributes to carbon neutrality

|

|

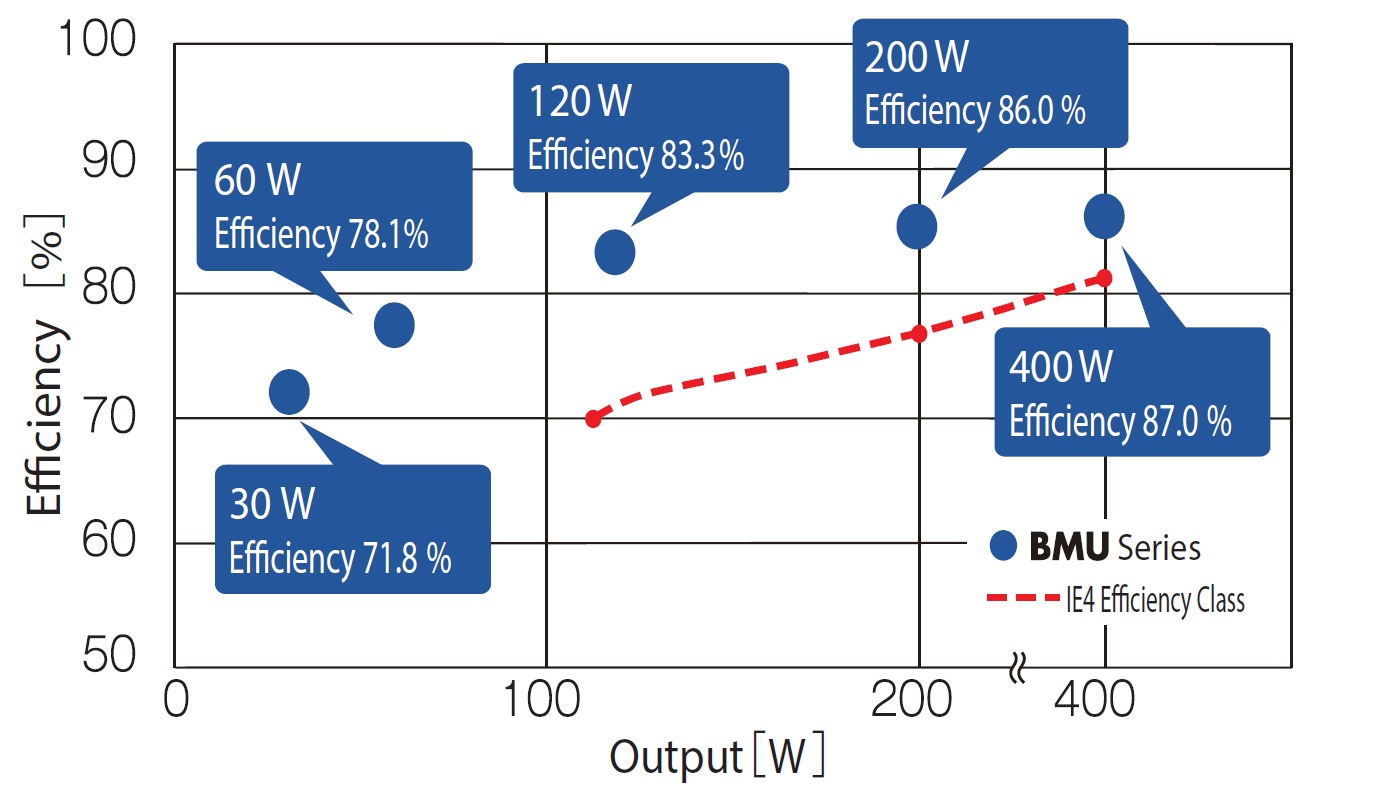

| High efficiency equivalent to IE4 * Brushless motors with built-in permanent magnets are more efficient than three-phase motors (induction motors). For example, the BMU series 200W meets the energy saving requirements with a motor driver efficiency of 86%, which exceeds the IE4 standard value of 75.8%. *Efficiency class specified by the international standard IEC60034-30-1, for induction motors of 120W or more. The efficiency value of IE4 is the value at the rated output of 50Hz, 4-pole machine. The efficiency value of the brushless motor is the value of the rated torque at the rated rotation speed. |

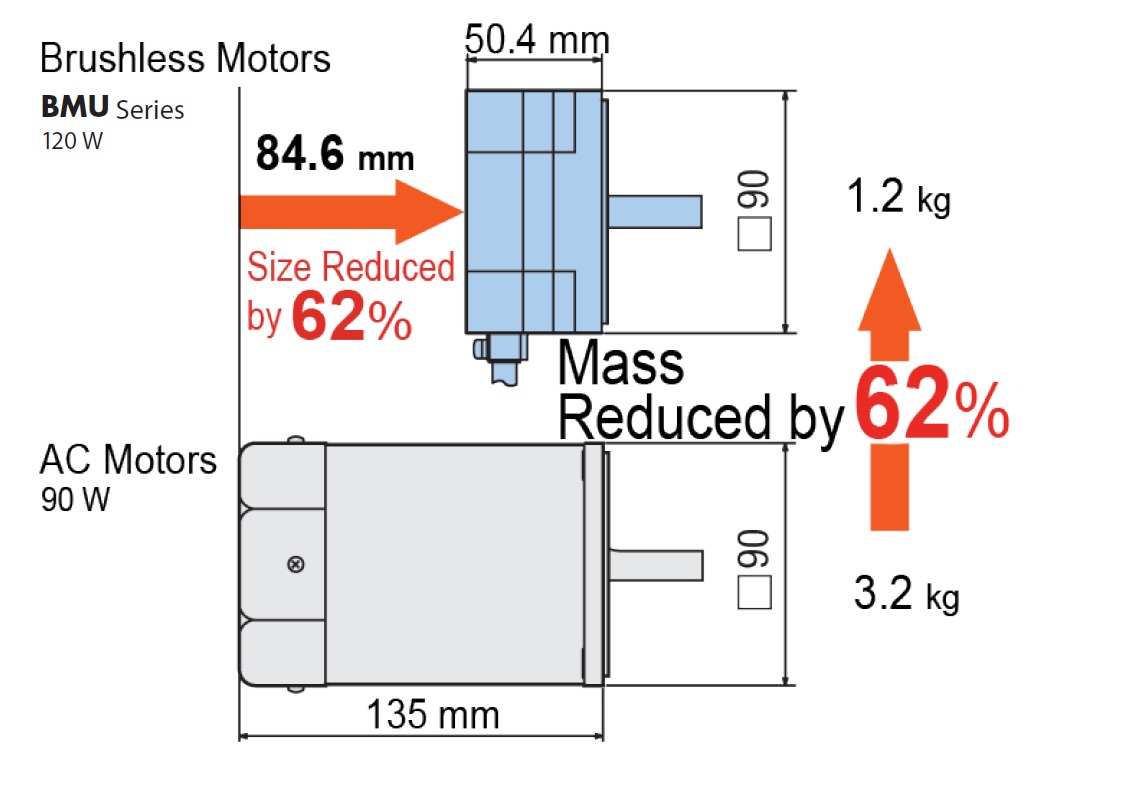

Compact and lightweight The brushless motor with a built-in permanent magnet is thin and has high power. For example, the overall length is 84.6 mm shorter than that of a three-phase induction motor with a mounting angle of 90 mm. Contributes to downsizing of equipment and resource saving. |

Features of design and manufacturing

|

|

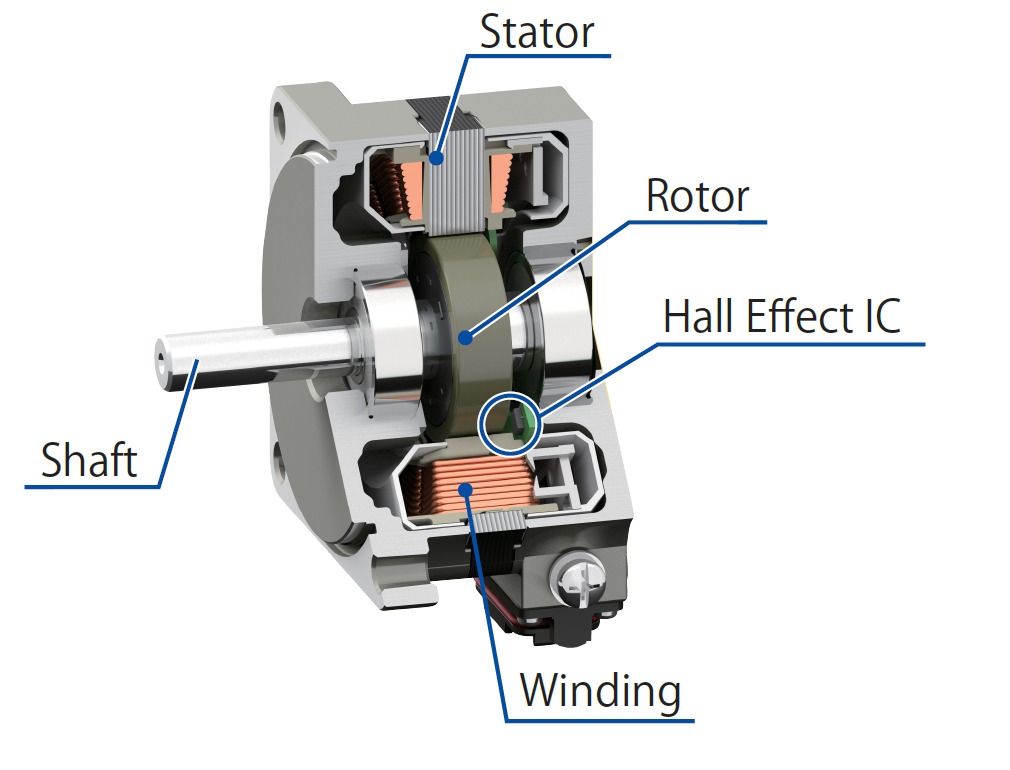

| Highly efficient design with reduced loss By winding a thick copper wire around the stator without any gaps and optimizing the material, thickness and shape of the electrical steel sheet, copper loss and iron loss are reduced. A compact and power-saving design is realized. |

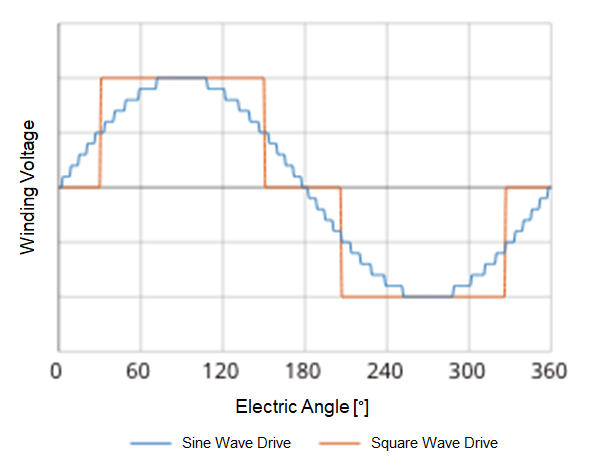

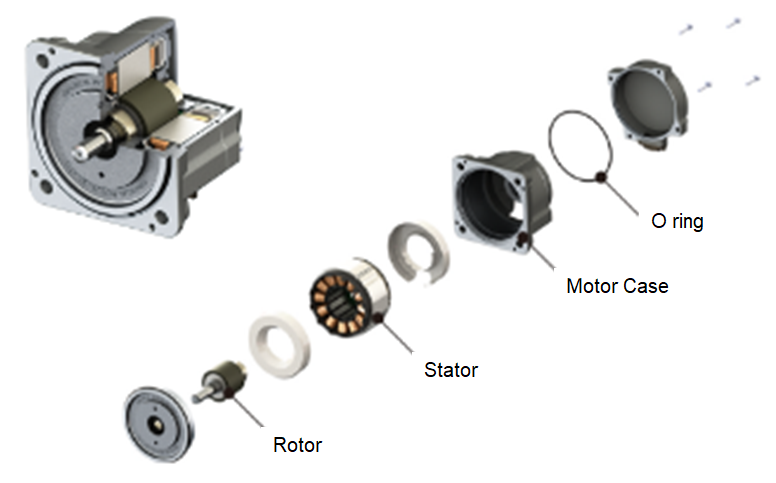

Rotor design and driver control that achieves low vibration and low noise The motor reduces the cogging torque that causes uneven rotation by design, adjusts the balance of the rotor (rotor), inspects it, and ships it. The driver realizes smooth operation by driving with a sine wave. Optimal operation is performed by reflecting the motor parameters in the control. |

|

|

| High reliability and long life Longer life than before. In addition, some models that specialize in device integration use bearings with high heat resistance. It also incorporates a creep-resistant structure that is resistant to eccentric loads by inserting rubber parts (O-rings) around the outer circumference of the bearing. The dedicated gear head is also highly strong and can be used for a long time with a rated life of 10,000 hours * 1 . * 1 Depends on the type and output of the gear head |

Dustproof / waterproof design that can be washed with water We also offer a dustproof and waterproof type that is resistant to water and dust. By adopting seal parts, water can be prevented from entering the inside of the motor, and it conforms to IP67 including the connector part. Stainless steel is used for the output shaft and screws, and a special coating is applied to the entire surface to prevent rusting. |

Availability

|

|

| Global support overseas standards We have a lineup of voltage specifications for single-phase 100V / 200V, three-phase 200V, and DC power input so that they can be used in major countries around the world. Each series has obtained UL / CSA standard certification, is EN standard compliant, and has CE marking. |

Delivered from one unit on various channels You can order from one prototype by WEB shop, phone, or email. Please contact us for mass production. You can also purchase overseas. Click here for more info |

For Singapore: 1800-842-0280

For Malaysia: +60-3-22875778

For Thailand: 1800-888-881

For Other countries: +65-6745-7344

Operating Hours

Mon - Fri: 9:00 AM - 6:00 PM (SGT)

Sat/Sun/Public Holiday: Closed