Cover Story on latest Industrial Trends

Electric Gripper that Supports Automation

| Latest trends in Industrial Robots | |

|

As a system integrator for FA robots, Tokuden Co., Ltd. continues to support customer manufacturing needs through solution systems, robot systems, and its FA trading company business. They serve a wide variety of customers, mainly in Shizuoka Prefecture, in the field of automobiles, textiles, pharmaceuticals, and food products. In this interview, we show actual examples of electric grippers that are used by Tokuden, as well as the latest trends in industrial robots and electric grippers that supports automation. |

Chapter 1: Examples of EH Series Electric Grippers

Checking the shape and machining accuracy of applicable customer workpieces and suggest appropriate grippers.

To begin, we spoke with Mr. Ota, General Manager of the Fuji Sales Office at Tokuden. As he works directly with customers, we asked him about the performance of Oriental Motor EH Series electric grippers.

In particular, we were interested in the adoption of EH Series electric grippers among customers. Can you tell us about the background behind the usage of electric grippers?

Ota: Electric grippers have been adopted for automated production equipment utilized in factories.They are used when slow and delicate gripping of lightweight workpieces is needed. We also considered air grippers, but air gripping can cause damage workpieces. They are also prone to dropping workpieces when there are decreases in air pressure. In contrast, electric grippers are able to produce a stable gripping force and can be used effectively for delicate gripping applications based on customer needs. In addition, the EH Series is compact and lightweight and is not affected by installation footprint restrictions within equipment. It also has a track record of increasing productivity by using a dual gripping mechnism axis within the equipment. So, it helps customers while ensuring that equipment operates stably.

I know some customers requires products for gripping applications. Is there a difference in demand between air and electric grippers?

Ota: In my experience, I'd say the ratio is about 50-50. Air grippers are inexpensive and have many uses for simple gripping tasks. Also, if they breakdown, they are quite easy for customers to replace it's parts. One thing to remember about electric grippers is that their gripping force needs to be adjusted. It is a big problem if a precision product scratches or damages workpieces. Therefore, we check the shape and machining accuracy of applicable customer workpieces first before suggesting appropriate grippers.

Chapter 2: Latest Trends in Industrial Robots

An increasing number of customers are collecting their own information and looking to us for solutions.

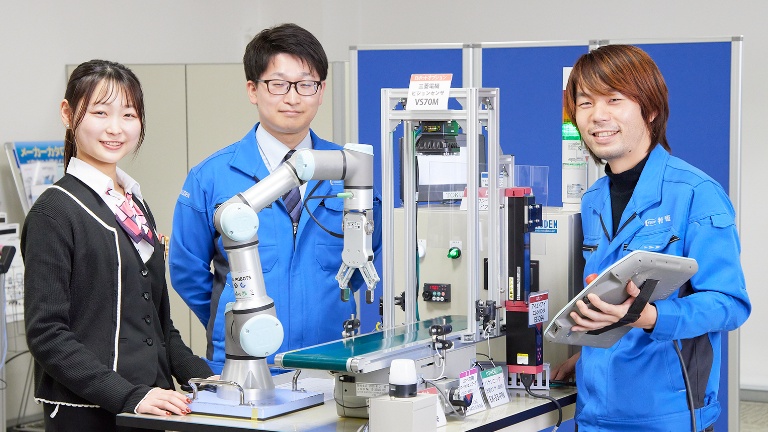

Akihiko Kameyama, Manager,

Sales Technology Section, Sales Department, Tokuden

Next, we spoke with the three representatives from Tokuden about the latest trends in industrial robots.

Robots are getting more and more attention in assisting labour saving and efficiency.

Kameyama: Inquiries about robots are generally increasing. Recently, there have been requests not only to entrust the construction of the entire system to a system integrator, but also to include training of the members (persons) who handles the system. After introducing the system, the customer has to handle it, so request includes the education aspect.

Have you noticed any changes in customer demand and usage of industrial robots?

Suzuki: It depends on the size of the company. Large enterprise customers are adopting robots at an accelerated pace. At a multi-product production site, it is necessary to modify the equipment (setup change) for each product. If robots are introduced there, it will be possible to reduce costs by simply changing the programming without having to frequently modify the equipment. There is an idea to utitlise robots in this aspect as well. In addition, some customers are appealing to their clients as a positive corporate attitude that they are working on the introduction of robots adoption. On the other hand, when it comes to small and medium-sized business customers, the pace of introducing robots are still lagging. In most cases, the proposal from our company is the trigger to introduce these robots.

In what type of scenarios are you suggesting robots to SME customers?

Suzuki: There are many timings for launching new lines. With an orthogonal axis, you can basically only do one task, so we often propose robots that can do a variety of things.

Kameyama: Recently, there are many instances where customers themselves are collecting information from websites, etc., and there are an increasing number of instances where we are asked if we can do something like this. I think we have to make proposals based on the latest technological trends.

Takahiko Suzuki, Group Leader,

SE Department, Tokuden

Chapter 3: Support for Introduction of Robot System

In June 2020, a Robot Lab was opened as a showroom where test operations can be performed

Tell us how your company is supporting the introduction of robots.

Suzuki: There are basically two ways we are doing this. One way is to undertake projects for entire systems, and the other is to sell individual robots. Also, when it comes to system construction, we listen to customer requests and propose ideas from scratch.

Kameyama: In regards to purchasing individual robots, large companies and SMEs have different objectives. Large companies often want to find new ways to use robots. For example, they might want to use transportation robots in conjunction with cobots. SMEs often purchase our products to enhance their own technical capabilities with the expectation of receiving after-sales support. Basically, they launch robot systems and then request our services for suggesting ways to operate them.

We opened a robot lab in June 2020. What kind of customers are visiting the lab?

Kurihara: We get many customers who are not knowledgeable of robots. Many of them have never operated an actual robot. So, we usually give them a brief explanation and then ask them what they want to achieve with robots. After this we try to support them by collaborating in-house.

I heard that you do tests on real robots in the robot lab.

Kameyama: We have a test that uses hands to grip things. When it comes to suction hands, we have several available to test various gripping methods. The aim is to give people ideas for specific usage scenarios, such as whether suction is possible with greasy workpieces.

Anna Kurihara, Sales Planning Section,

Sales Department, Tokuden

Chapter 4: Trends and Requirements of Robotic End Effectors

Compatibility and connectivity with accessories are also key factors when selecting products.

When you suggest a robot to a customer, what is entailed in the selection process?

Suzuki: From the standpoint of maintenance, if the customers is already using a robot, we suggest that they continue to use the same manufacturer. Other considerations include whether the robot is well-suited for the application and whether it is compatible with accessories.

What about the selection of end effectors?

Suzuki: It is basically about finding devices that are suitable for workpieces. If we receive requests for airless devices, we will usually suggest the use of electric effectors. Other aspects, such as wiring, are also important. If connections are made along the arm, this will restrict movement, so it is better to utilize a design where connections are made inside the arm. In the case of cobots, we suggest hands that can be used by simply connecting them to connectors.

Kameyama: After this, it is necessary to choose a device with the right opening width from our lineup of products. In terms of maintenance, people have the impression that electric hands require more upkeep. However, I tend to think that air based products are more likely to cause temporary stoppages due to clogging and malfunctions. But I guess each product has its advantages and disadvantages.

Suzuki: When it comes to opening and closing, not only is the stroke important, but also the way it opens. Even with parallel chucks, the way the chuck is gripped and the way the shaft moves differ depending on the manufacturer, so this is also a key point in the selection process.

What about size and availability?

Suzuki: If space constraints require a small robot, I suggest a small and lightweight one, but if there are no constraints, then I don’t think size is too much of a concern. Availability is not a concern when deploying new robots. It usually takes several months to deliver a robot, so it is basically impossible to have requests for immediate delivery. However, I can imagine that customers are concerned about immediate availability of products when dealing with breakdowns.

Suzuki: They want highly durable electric grippers that are waterproof and dustproof. For example, this includes hand applications, such as taking drugs out of freezer cases and working in environments with corrosive gases. These may sound like special applications, but if electric grippers can replace the work of humans in these areas, we will be able to broaden the range of our proposals to customers.

Chapter 5: EH Series Electric Grippers that Support Automation

Compatibility and connectivity with accessories are also key factors when selecting products.

When you suggest a robot to a customer, what is entailed in the selection process?

Yuki Arai, Section Manager,

Product Planning Department, Sales Division, Oriental Motor

We have released an end effector that incorporates a αSTEP AZ Series EH Series electric gripper. It is available as either a 2-finger type or 3-finger type and is distinguished by its compact size and light weight. Its gripping force can be adjusted to achieve a delicate grip that does not damage workpieces. We also offer flanges that can be attached to commercially available robots. I would like you to give us your honest opinion on this product.

Suzuki: It is basically one of the smallest electric hands I have ever seen. For the 3-finger electric type, I’ve never seen a product this small. I think its size is definitely an advantage. It also has a unique rotating and gripping motion. I don’t think other companies offer products with this type of gripping.

As for the movement of the 3 fingers, they are designed to grip cylindrical objects such as test tubes and plastic bottles. Small and lightweight drivers that support a wide range of interfaces can also be installed near the housing of the electric gripper.

Suzuki: By installing a driver behind the hand, I think it can be used for light, transportable industrial robots. If using the EH Series, we need to utilize bellows cable covers because the cables are laid along the outside of the motor. Depending on the application, I think it would be necessary to consider cable placement, since this type of configuration limits the cable’s range of motion.

Kameyama: From the viewpoint of sales, its reasonable price makes it attractive compared to overseas products. I would like to see it certified by various robot manufacturers and support plug and play to simplify connectivity. Even if these enhancement increase the cost, I think it could still be offered at a very reasonable price.

Finally, as a system integrator, what is your outlook for the future?

Suzuki: Technology continues to evolve every day, so we would like to actively incorporate new technologies and offer a variety of products that help solve our customers’ challenges.

Courtesy of Tokuden Co. Ltd.

| Head Office:9-11-5 Futaba-cho, Namazu City, Shizuoka URL:https://www.kk-tokuden.co.jp/ [Business Profile] Design, manufacture, and sales of FA/automation systems, robot systems, ICT (IoT) systems, and servo mechanisms |

|

More Information on EH Series Electric Grippers

Click to Return to Technical Articles page