Low-Speed Synchronous Motors

SMK Series

- Rotates at Low Speed in Sync with the Power Supply Frequency

- At 50 Hz, 60 r/min, At 60 Hz, 72 r/min

- Simple Positioning Operation is Possible as It Stops Instantly when the Power is Turned Off

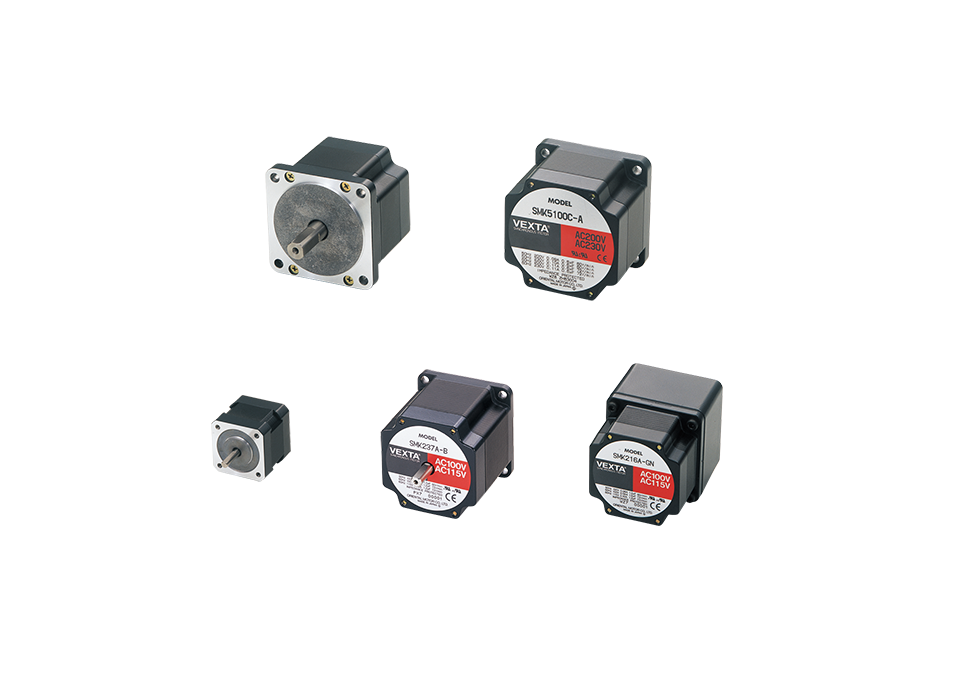

- Frame Size 42 to 90 mm

Features | Low-Speed Synchronous Motors SMK Series

Low Speed and Synchronized Rotation

It rotates at low speed, precisely synchronized to the power supply frequency.

The rotation speed remains unchanged, even if the load fluctuates.

At 50 Hz 60 r/min (30 r/min)*

At 60 Hz 72 r/min (36 r/min)*

- *The values in parentheses ( ) are for SMK014MA-□.

Continuous Rated Permanent-Split Capacitor Motor

A permanent-split capacitor motor that can be easily driven using only a capacitor (the SMK5□ also requires an external resistor). It can be driven at a continuous rating even in bidirectional operation.

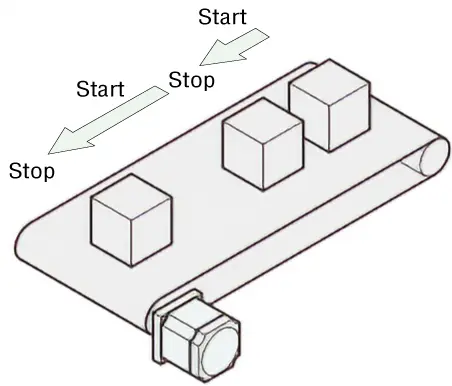

Excellent Start, Stop, and Reversing Characteristics

If the inertia load of the motor is within the permissible load inertia, the motor can start, stop, and reverse within 1.5 cycles of the power supply frequency (0.03 seconds for 50 Hz, 0.025 seconds for 60 Hz).

-

Ideal for transportation conveyors that repeatedly start and stop.

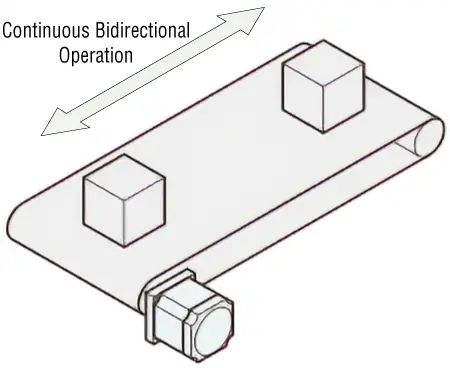

-

Bidirectional operation can also be repeated continuously.

It Can Also be Applied to Positioning.

Simply turn off the power supply to stop the motor. Within the motor permissible load inertia, stopping within a 10˚ tolerance is possible. If you use a highly accurate switch, simple and highly accurate positioning is possible.

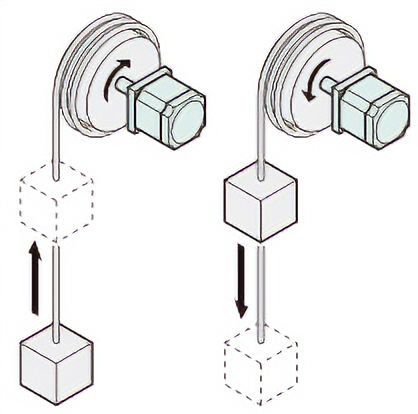

Capable of Winding Down Operation

It rotates at constant speed, even when wound down. It is also suitable for applications where vertical movement at the same speed is needed.

You can also hold the load.

Low-speed synchronous motors are structured the same as stepper motors and use permanent magnets in the rotor, which automatically gives them holding force. A large holding force can be utilized by using a gearhead.

- Using a DC power supply lets you obtain an even higher holding torque.

The double shaft type is also available as standard.

This is useful when attaching clean dampers to absorb vibration and slit plates for return-to-home.

Gearheads can be used.

We also offer a pinion shaft type usable with Oriental Motor’s standard noise reduction GN type gearheads. There are 20 different gear ratios available and they are replaceable.

- *The SMK0A-□ is a geared motor including a special gearhead and motor. The gearhead cannot be replaced.

Applications

-

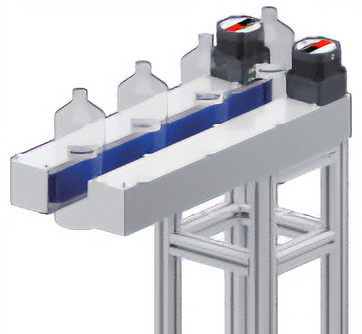

Side Conveyor

The motor is synchronized to the power supply frequency and highly responsive, making it ideal for applications that need multiple axes to be synchronized.

-

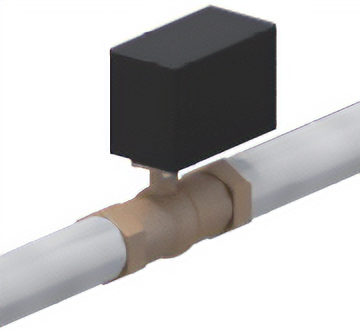

Opening and Closing the Valve

The motor alone has a stopping overrun of less than 10˚, making it ideal for simple positioning operations.

-

Turn Tables, Display Equipment, etc.

The motor can be operated alone at low speed, and at even lower speed by adding gearheads, making it ideal for applications where the load is turned slowly and continuously.

-

Cutter Vertical Operation

Connecting it to a DC power supply allows holding force to be generated, making it ideal for applications where the load is held while stopped.

Product Line

| Type | Frame Size [mm] |

Torque [N·m] |

Standstill Holding Torque [mN·m] |

|---|---|---|---|

| Round Shaft | 42 | 0.11~0.14 | 4.5~10 |

| 56.4 | 0.37 | 25 | |

| 85 | 1.02~2.1 | 36~89 | |

| Geared Motor* | 42 | - | 9 |

| GN Gear Cutting* | 60 | 0.16 | 15 |

| 90 | 0.5 | 36 |

- *Torque and standstill holding torque are the values at the motor output shaft.

Narrow down Products