Brushless Motors

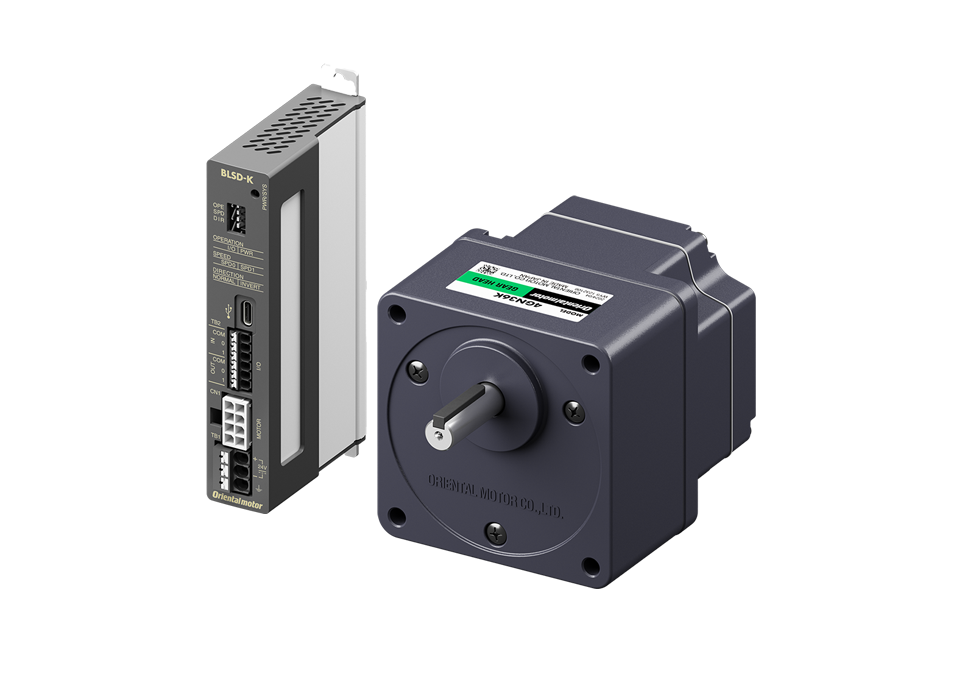

BLS Series

- 24 VDC Input, Compact Driver

- Supports RS-485 Communication (RS-485 communication type driver)

- A Brushless Motor That's as Simple to Use as an AC Motor

- Easy Wiring, Easy Drive With Power ON/OFF

- Can Use the Same Gearhead as an AC Motor

- Speed Control Range (Output power)

100~2000 r/min (25 W, 40 W, 90 W)

100~4000 r/min (30 W, 60 W, 120 W)

Features | Brushless Motor BLS Series

Overview and Applications

2-Minute Explanation of the BLS Series

Watch the video to see the features of the BLS Series, which are as easy to use as an AC motor.

- ・Output Power

- 25 W, 30 W, 40 W, 60 W, 90 W, 120 W

- ・Power Supply Input

- 24 VDC

- ・Easy wiring, easy drive with power ON/OFF

- ・Can use the same gearhead as an AC motor

- ・Speed Control Range

- 100~2000 r/min (25 W, 40 W, 90 W)

100~4000 r/min (30 W, 60 W, 120 W)

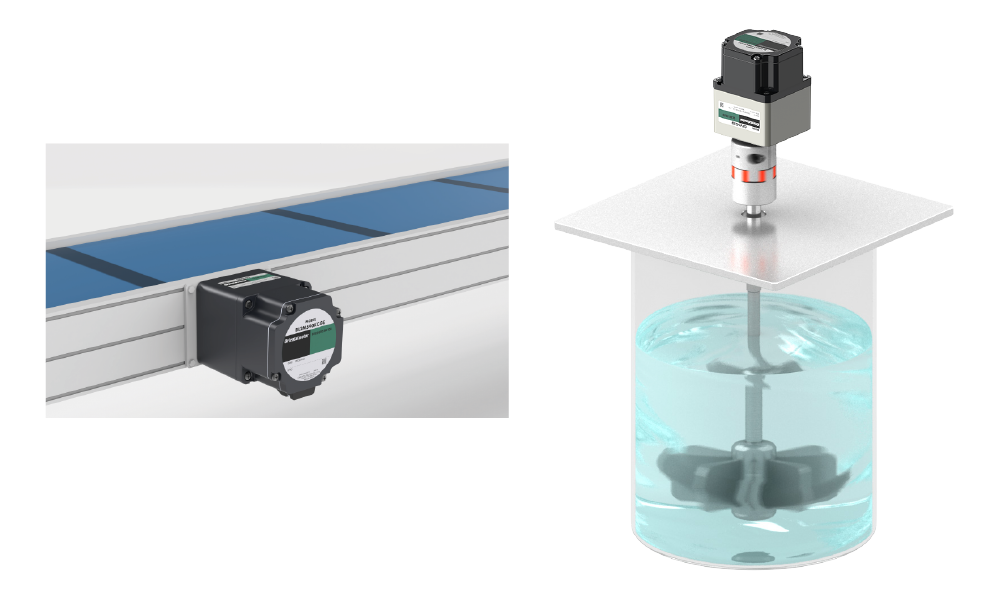

Applications

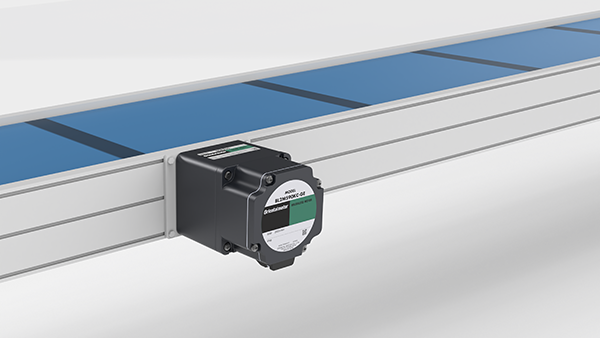

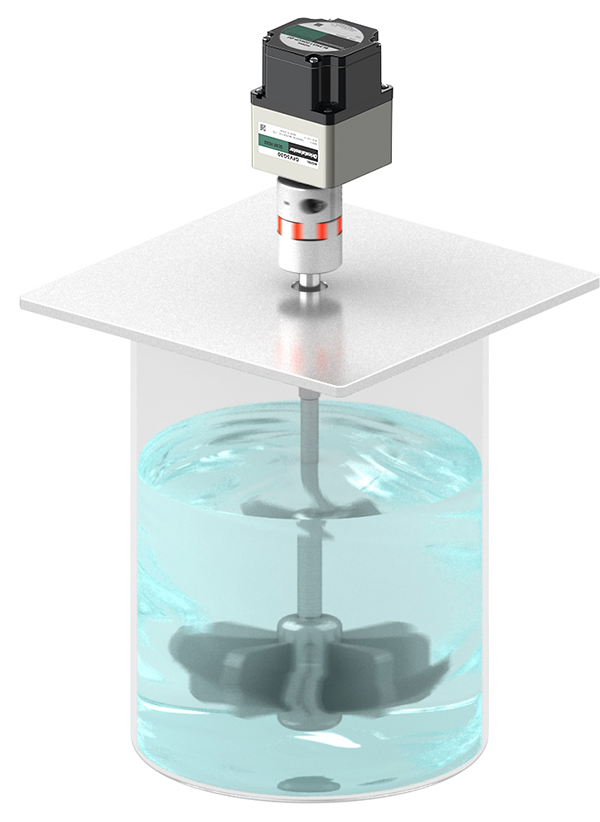

The BLS Series is suitable for applications that require constant speed and continuous operation.

The motor is equipped with a small sensor for feedback control, which reduces fluctuations in the motor’s rotation speed even when the load changes.

Belt Conveyor

Agitator

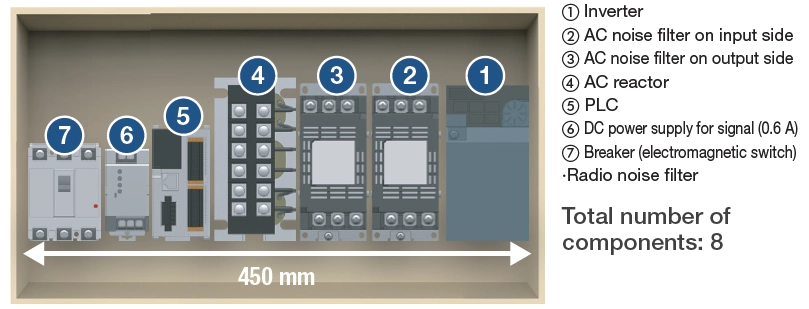

More Cost Reductions

Reduced Electricity Costs

Brushless motors are efficient and energy-saving.

As a result, electricity costs can be reduced by 20 % compared to an AC motor + inverter.

Reduced Running Costs (Electricity costs over 3 years)

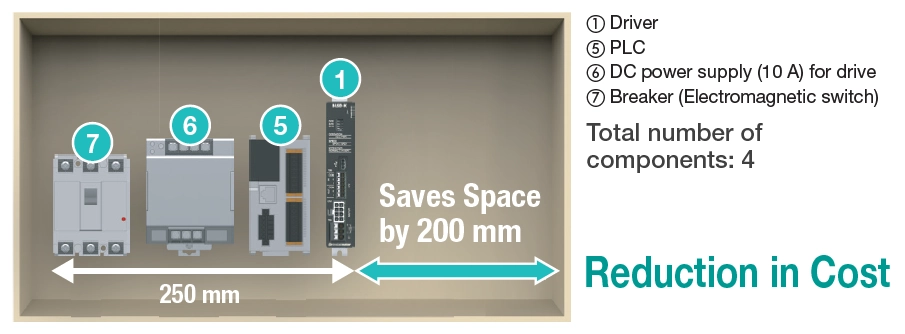

The 24 VDC input brushless motor and compact driver can reduce the cost of parts, space used, and the wiring work in the control cabinet.

■ Parts used for AC motor + inverter

■ Parts used for BLS Series

More Compact

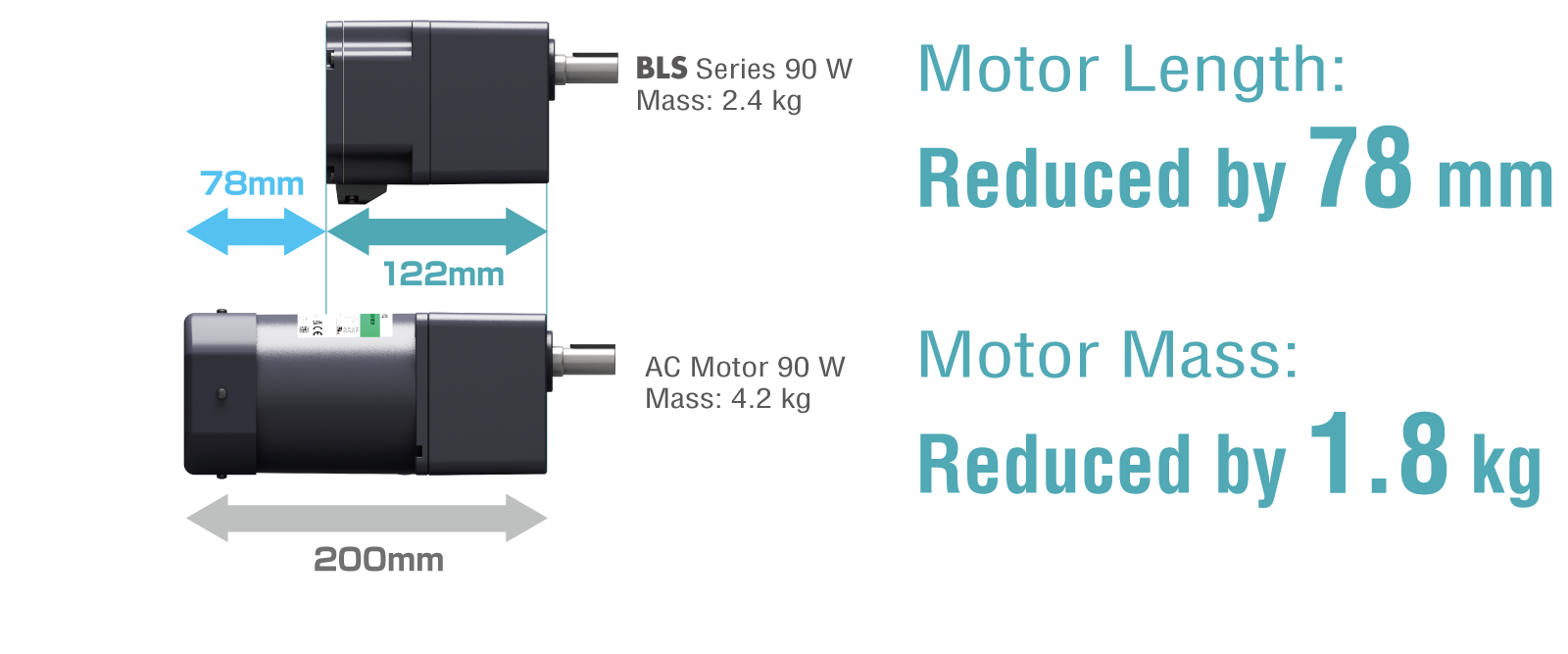

Reduction of Motor Size and Weight

Compared to an AC motor with a 90 mm frame size, the overall length is 78 mm shorter.

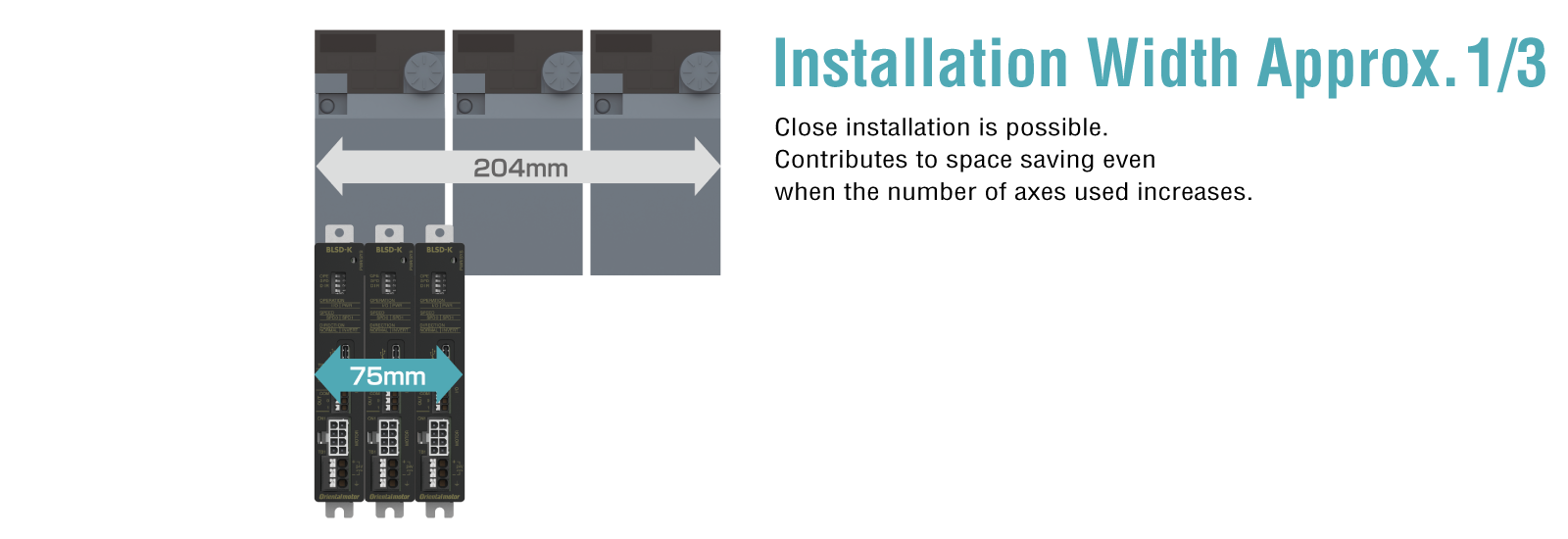

Driver Size Reduction

A volume reduction of 65 % compared to the size of a typical inverter.

Simpler Like an AC Motor

Can Use the Same Gearhead as an AC Motor*. Easy to Change the Motor Without Equipment Modification

For the same output power, the motor’s frame size and pinion specifications are the same as AC motors.*

The same gearheads (GN gearhead/GE gearhead) can be used as with AC motors.*

- *For a standard (AC motor compatible) type.

Easy to replace if the gearhead is the same!

- ・

- Possible to only change the motor without needing to modify the equipment

- ・

- The shaft’s diameter is also the same for motor/gearhead replacement, so couplings and other parts can be re-used

- ・

- As the parts are the same, this enables labor reduction for inventory control and maintenance

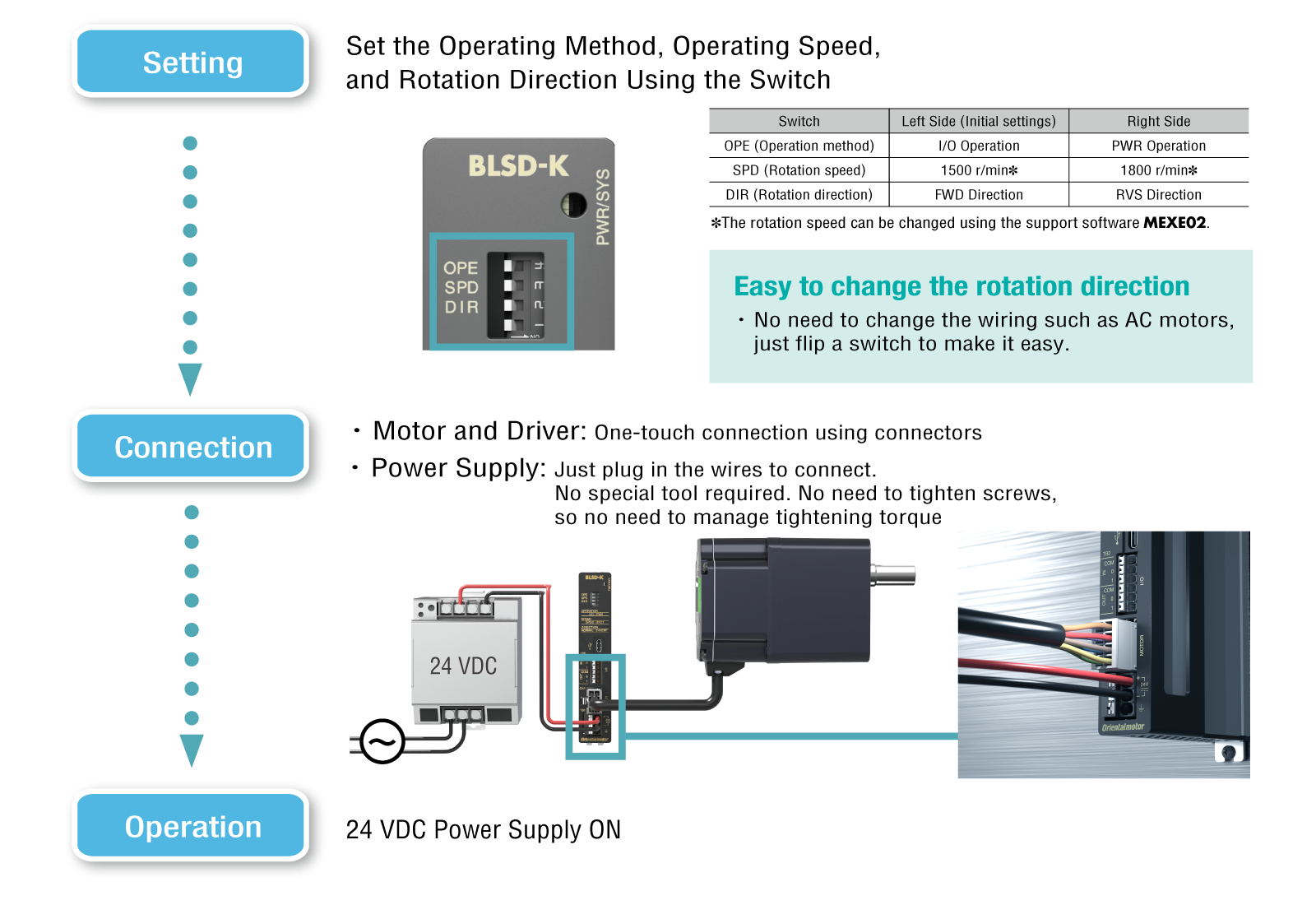

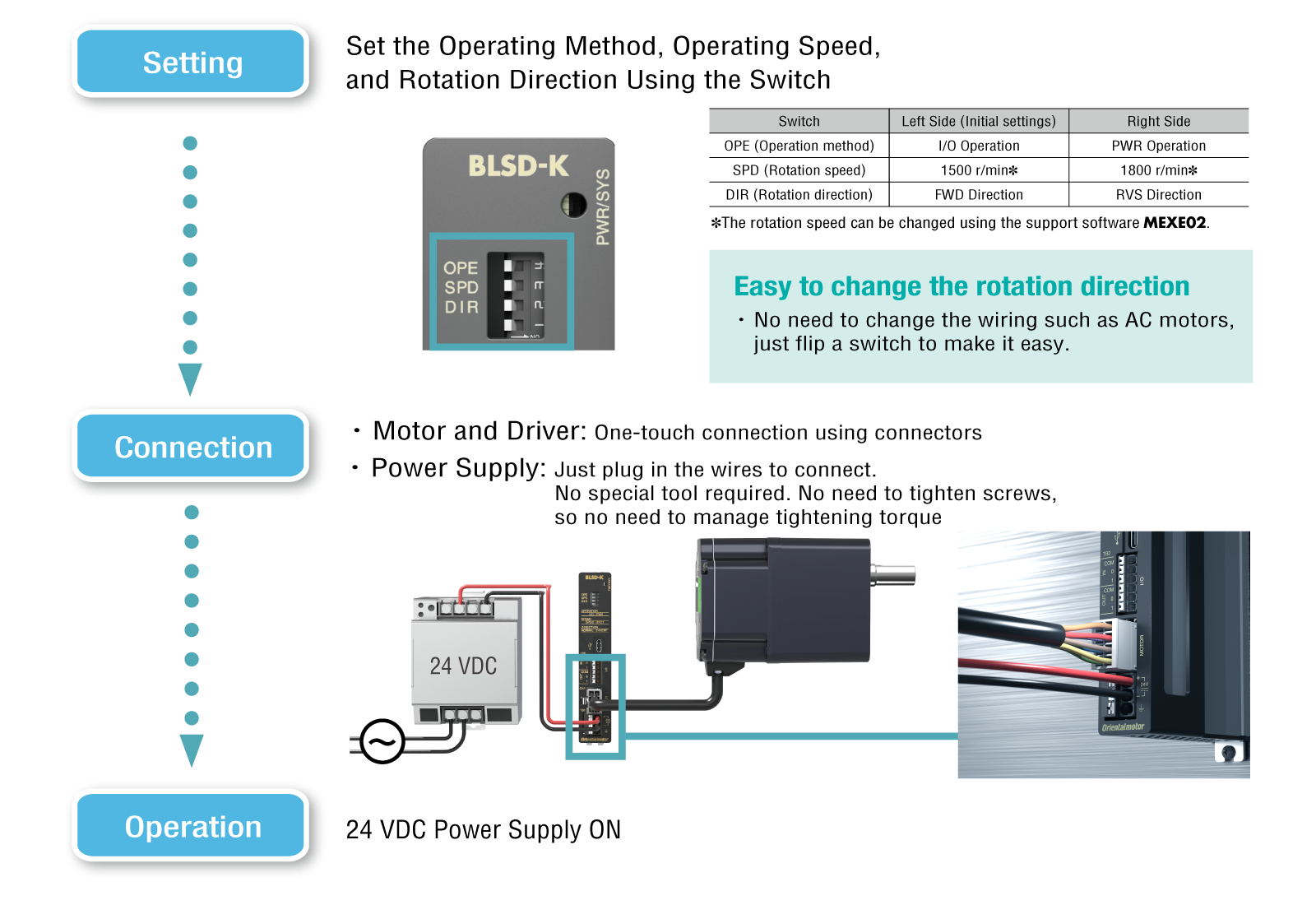

Very Simple to Set Up, Connect, and Operate

More Reliable

I Want to Extend the Life of My Equipment

The BLS Series of high-efficiency motors with low heat generation have a longer service life than AC motors.

- Why the longevity?

The bearing grease’s lifespan is one of the factors that decides the motor’s lifespan. Since the grease’s lifespan is affected by heat, the low heat generation of the BLS Series motor lengthens its lifespan.

Brushless Motor BLS Series: 40,000 hours

AC Motor (Induction motor): 30,000 hours

Estimated lifespan conditions

- ・

- Continuous, unidirectional operation

- ・

- Rated torque, constant load

- ・

- Rated Speed

- ・

- Ambient temperature 30 °C

Click here for information about the estimated lifespan

24 VDC Input Makes Global Equipment Development and Safety Design Easier

Easy to Develop Globally

- ・

- BLS Series products can be used worldwide

- ・

- No need to select and design for each country's voltage/frequency like AC motors

- ・

- Not subject to the Low Voltage Directive

Safety Design, Low Noise

- ・

- 24 VDC input is less than the hazardous voltage (60 VDC)

- ・

- Significant reduction in designing safety measures, etc.

Equipment Size Reduction

- ・

- DC power supply is easy to control. The structure of the entire equipment is simple

- ・

- Simplification of the control cabinet, making the entire equipment more compact

I Want to Reduce Speed Fluctuations

The motor is equipped with a small sensor for feedback control.

This reduces fluctuations in the motor’s rotation speed even when the load fluctuates.

Speed Regulation (Load)

±0.2 %

Selectable Driver: RS-485 Communication Type & Simple Type

| RS-485 Communication Type | Simple Type |

|---|---|

|

|

|

|

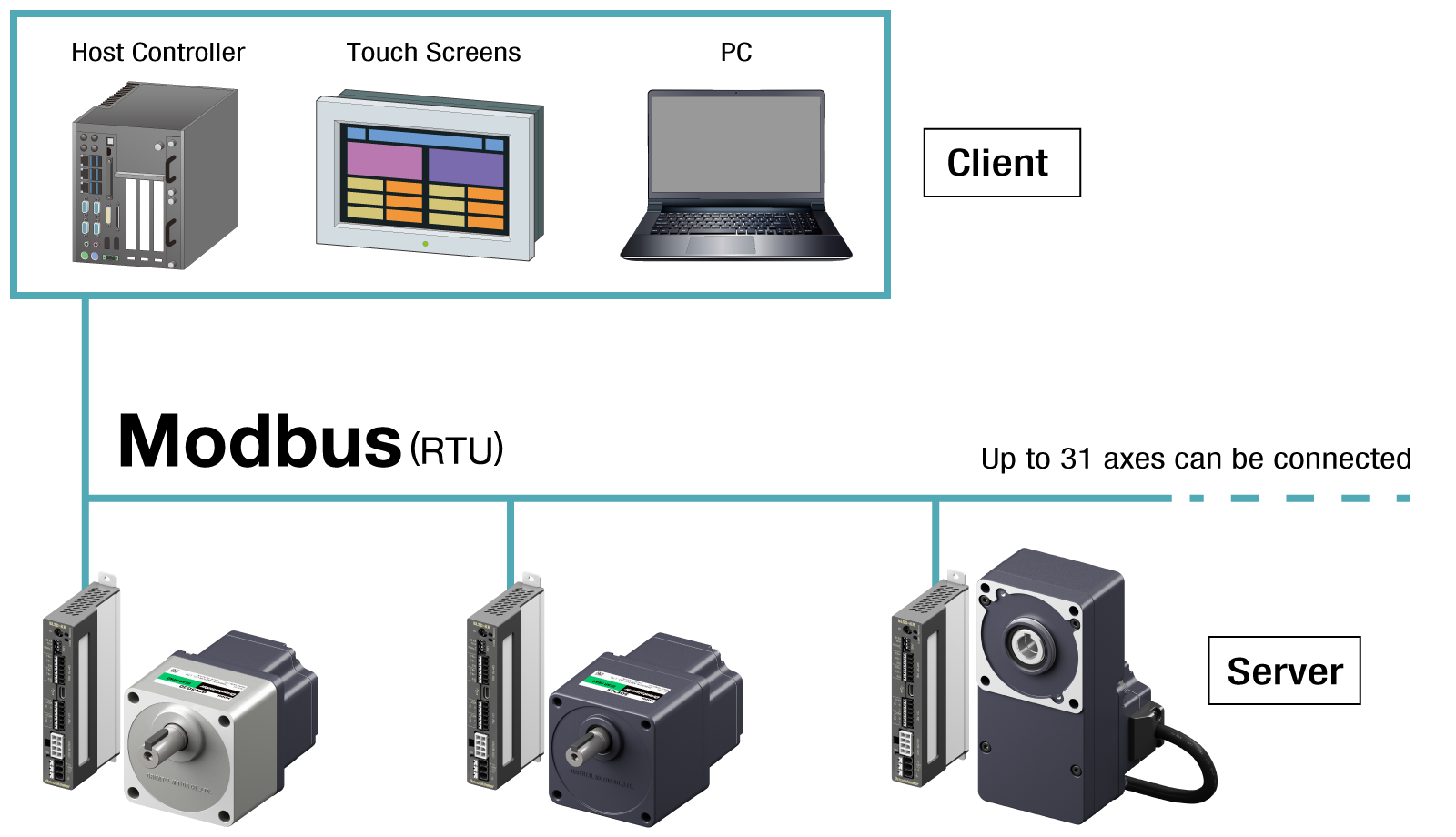

RS-485 Communication Type Driver

The RS-485 communication type is compatible with interface for the Modbus (RTU) protocol. In the FA market, where automation has been increasing in recent years, information exchange between devices is performed through communication, but RS-485 communication type can be easily supported.

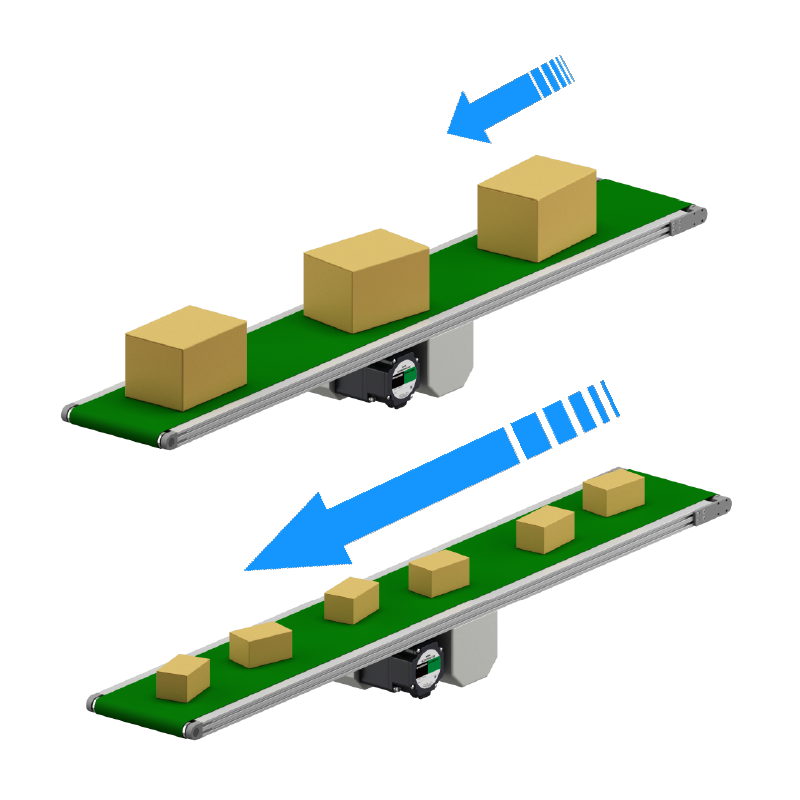

Main Function 1: Free to create a driving profile - Direct Data Operation

Direct data operation is a mode in which data can be rewritten and started simultaneously. Suitable for applications such as speed adjustment in cooperation with other equipment and speed change according to the conveyed object.

| Operation Data Type | Description |

|---|---|

| Operation Mode | Sets the operation mode. |

| Speed | Sets the operating speed. |

| Acceleration Time | Sets the acceleration time. |

| Deceleration Time | Sets the deceleration time. |

| Torque Limiting Value | Sets the torque limiting value. |

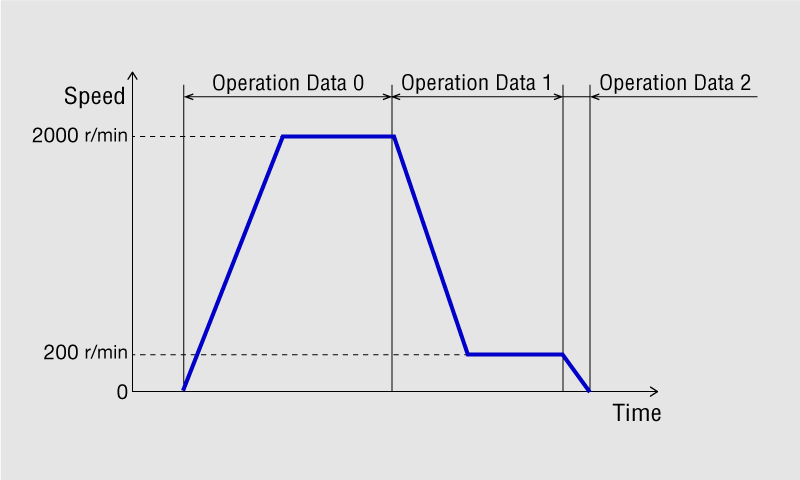

Main Function 2: Equipped with simple sequence function

Equipped with sequence functions such as data linked operation, event jump, and data transfer.

Using the support software MEXE02 enables configuration, can be simplifies the sequence program of the host controller.

Operations of two or more operation data number can be linked to enable multi-speed operation.

Simple sequence operations can be performed by combining the operation method settings and the event jump function.

| Operation Data No. | Operating Mode | Speed [r/min] |

|---|---|---|

| 0 | Continuous Operation | 2000 |

| 1 | Continuous Operation | 200 |

| 2 | Deceleration Stop | 0 |

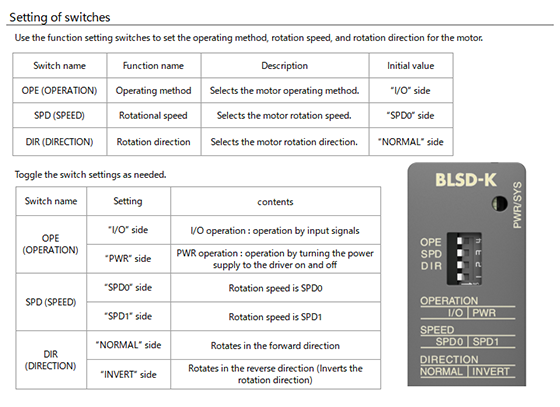

Simple Type Driver

The driver that can be easily operation in three steps with setting, connecting, and power ON/OFF.

Easier to Use, Easier to Choose

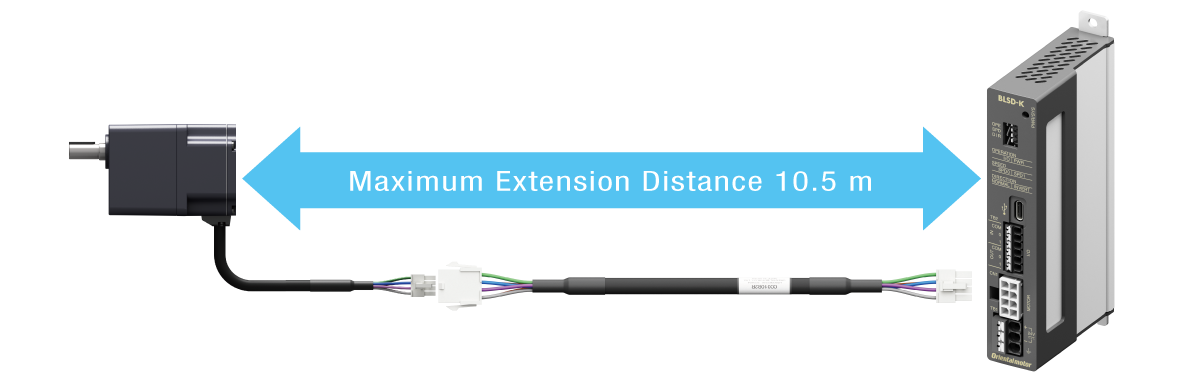

Cable Extension Distance 10.5 m

The maximum extension distance between the motor and driver is up to 10.5 m.

Can Use One Driver Model for Motors With Any Output Power

Any motor can be operated using one driver model.

Since the parts can be standardized, inventory and maintenance workloads can be reduced.

The Gearhead Can be Selected Based on the Required Application

| Type | Standard (AC motor compatible) Type | High-Strength, Long Life Type | |

|---|---|---|---|

| External View |

|

|

|

| Overview | Same gearhead as Oriental Motor’s AC motors Example) Gearhead product name 4GN□K |

Gearheads for brushless motors High permissible torque, long life Example) Gearhead product name GFV4G□, GFS4G□FR |

|

| Output Power of Assembled Motors | 25 W, 40 W, 90 W | 30 W, 60 W, 120 W | |

| Maximum Permissible Torque (When the frame size is 90 mm) |

20 N·m | 30 N·m (Parallel shaft gearhead) 65 N·m (Hollow shaft flat gearhead) |

|

| Gearhead Rated Life | 5000 hours | 10000 hours | |

- A number indicating the gear ratio is specified where the box □ is located in the product name.

Made Easier With the MEXE02 Support Software

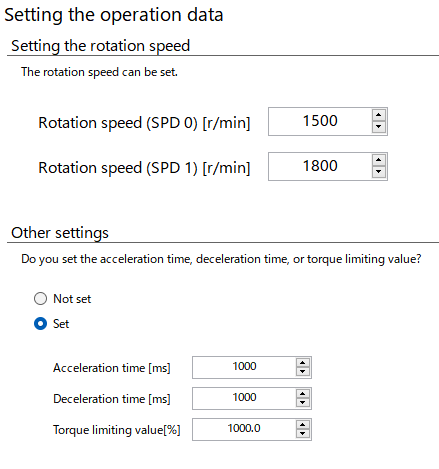

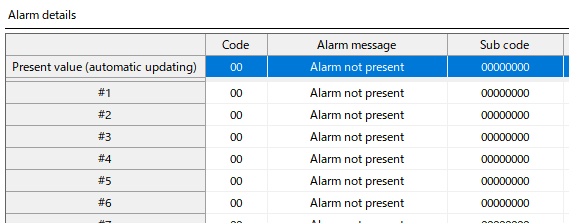

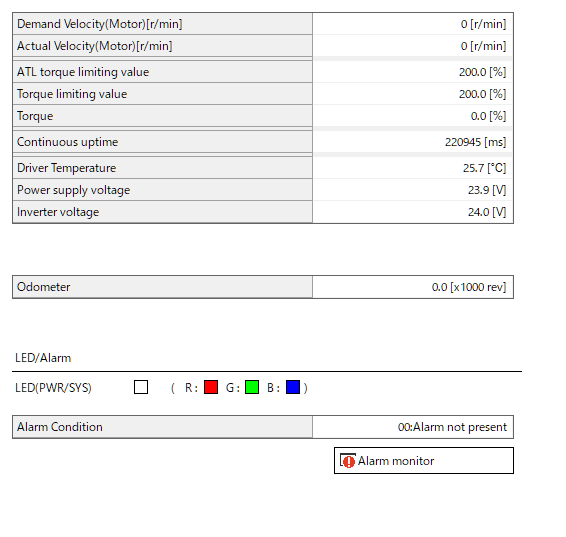

The Free MEXE02 Support Software Allows for More Detailed Configuration and Monitoring

The MEXE02 support software allows data setting and monitoring to be carried out simply via a PC.

The software can be downloaded for free.

(Please use Ver.1.0.1.0 made for the BLS Series.)

Start-Up Operation Setting Support Wizard

Related Products

Brushless Motors

BLH Series

- 24 VDC Input, Compact Driver

- Ideal for incorporating in equipment

- RS-485 Communication Compatible

- 15~100 W, (80) 100~3000 r/min

Brushless Motors

BLV Series R Type

- Battery-powered 24 VDC compact driver

- Compact and High Output Power, Ideal for AGVs

- Modbus/CANopen communication supported

- 60~400 W, 1~4000 r/min

Stepper Motors

PKP Series/CVD Series SC Type Driver

- Easy control with forward/reverse input

- 2-speed operation

- 0.02~600 r/min

Narrow down Products

Download

Operating Manual

Support Software

Support Software MEXE02

Ver.1.0.1.0 made for the BLS Series