Compact Electric Cylinders DRLII Series/

CVD Series Pulse Input Type

- A Compact Structure That Integrates a Ball Screw and Stepper Motor

- Stroke 25 to 100 mm

- Ultra-High Precision Positioning

- Pulse Input

Features | Compact Electric Cylinder DRLII Series/CVD Series Pulse Input Type

Features of Compact Electric Cylinders

Significantly Fewer Parts and Required Assembly Time

The compact body houses the entire linear motion mechanism.

Some of the conventional parts have been eliminated, so the time required for equipment design and product selection is shortened.

Furthermore, the number of man-hours required for assembly and the adjustment of installation accuracy can be reduced, contributing to higher productivity.

Compact and Lightweight

In this structure, the rotor is hollowed out and the ball screw is housed within it.

Some customer-supplied parts, such as couplings and ball screw bearings are no longer required, resulting in a more compact and lightweight design.

Low Cost of Entry

Mechanical components such as the ball screw are compactly integrated and available from 51,900 JPY.

- Rolled Ball Screw Type 51,900 JPY~

- Precision Ball Screw Type 92,000 JPY~

(This is the total price of the compact electric cylinder and driver.)

High Precision Positioning

A Ball Screw Nut is Jointed to a Hollow Rotor

By combining components with coupling rigidity, etc., the backlash effect is reduced and highly accurate positioning can be achieved.

About the Internal Structure

The DRLII Series has a hollow rotor section that allows the ball screw to be housed inside. The ball screw nut rotates as the hollow rotor rotates, and the ball screw shaft operates in linear motion by installing an anti-spin mechanism* at the end of the ball screw.

There are 2 types of ball screws: precision ball screws for minute feeds and high precision positioning, and rolled ball screws for general positioning that are reliable.

The ball screw shaft is housed inside the hollow rotor, ensuring maximum stroke in a short overall length. In addition, a large-diameter bearing is located around the periphery of the ball screw nut to directly receive the large axial load generated during linear motion.

- *Not required for guide type and table type.

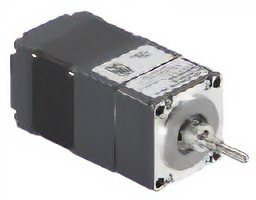

Uses Stepper Motors that Stop Precisely

The DRLII Series Uses a Stepper Motor.

The positioning accuracy of a single step increment of a stepper motor is very high, and it can move forward or backward with precision. Also, because hunting, the tiny movements of the axis during stopping, does not occur, a stop position can also be held precisely.

Choose from 3 Types to Suit the Application

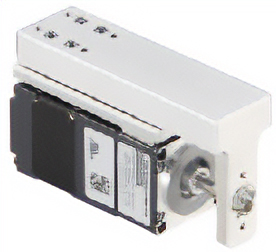

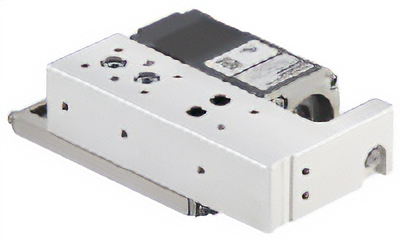

| Type | Guide Type | Table Type | Non-Guide Type |

|---|---|---|---|

| External View |

|

|

|

| This product includes a guide that can fix loads on the compact electric cylinder. Directly installing the load is easy. |

This product includes a guide that can fix loads on the compact electric cylinder. Directly installing the load and body is easy, and the limited height of the moving part allows easy transportation. |

This product can be incorporated directly into the customer's equipment, or it can be used as a compact thrust axis in the equipment's load transportation guide. |

Additional Functions and Others

The "With Adjusting Knob" and "With Electromagnetic Brake" additional functions are available for every type. In addition, the non-guide type DRLM28, DRLM42, and DRLM60 are available with a longer stroke.

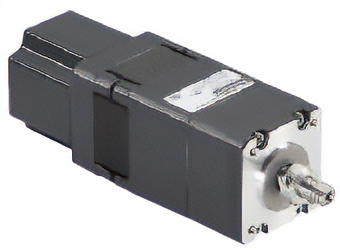

With Adjusting Knob

The position can be adjusted manually when the power supply is OFF. This function is useful during equipment maintenance.

With Electromagnetic Brake

The stop position can be held when the power is OFF.

Since the load will not fall in the event of power failure or disconnection, it can safely be used even when installed in the vertical direction.

Driver Features

Product Line

Please purchase the compact electric cylinder, driver, and connection cable separately.

| Type | Frame Size [mm] |

Stroke [mm] |

Thrust [N] |

|---|---|---|---|

| Guide Type | 20 | 25 | 15 |

| 28 | 30 | 30 | |

| 42 | 40 | 30, 100 | |

| 60 | 50 | 300 | |

| Table Type | 20 | 25 | 15 |

| 28 | 30 | 30 | |

| Non-Guide Type | 20 | 25 | 15 |

| 28 | 30, 60 | 30 | |

| 42 | 40, 100 | 30, 100 | |

| 60 | 50, 100 | 300 |

Narrow down Products

Download

Catalog

L-144

Compact Electric Cylinder DRLII Series/CVD Series Pulse Input Type/RS-485 Communication Type