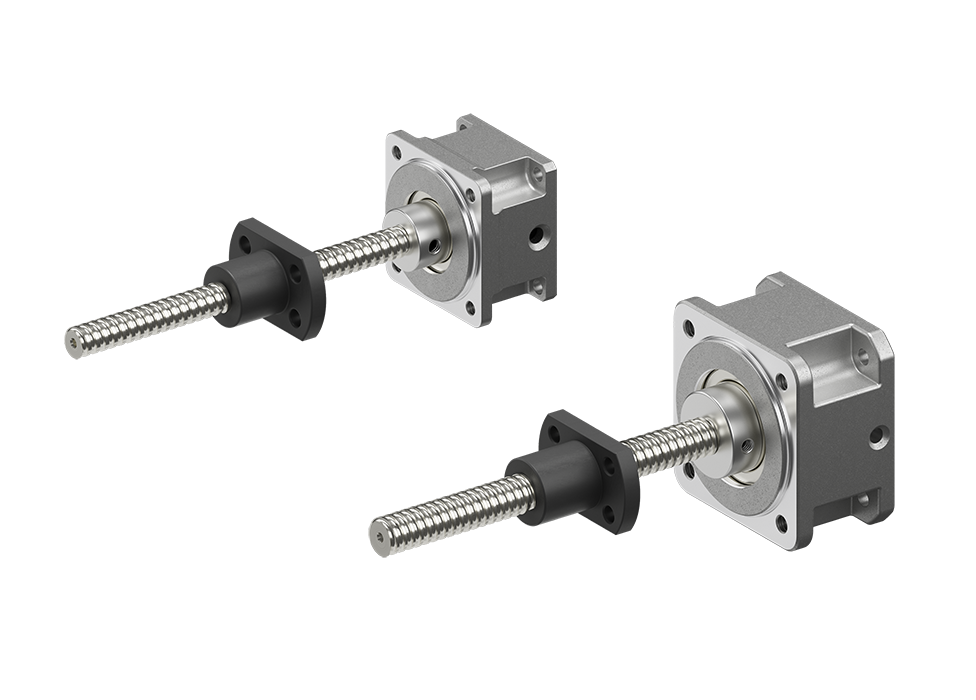

Mounting Adapter for Linear Actuator

- Achieve linear motion by assembling with a stepper motor

- Use a Lead Screw and Wear-Resistant Resin Nut

- Frame Size 30/42 mm, Stroke 50∼300 mm

- Thrust, Self-Locking Force: Maximum 100 N (frame size: 42 mm)

Features | Mounting Adapter for Linear Actuator

- Overview and Applications

- Frame Size is 42 mm, Thrust is 100 N

- Self-Locking Force* is 100 N Max. (Frame size 42 mm, lead 2 mm). Load Holding is Possible

- Assembly is Easy Without Couplings. Equipment Can be Designed in Less Space and in Less Time

- Supports the Axial Load Directly

- Wear-Resistant Resin Nut Used

- A Wide Variety of Motors and Drivers for More Reliable Motion

- Applications

- Product Line

Overview and Applications

Watch the video to see the features of the mounting adapter for linear actuator.

Frame Size is 42 mm, Thrust is 100 N

- Permissible thrust 100 N, stroke 50~300 mm, permissible speed 180 mm/s

- High thrust and high speed despite its small size. Contributes to Reduction of Equipment Takt Time

| Frame Size [mm] |

Lead [mm] |

Stroke [mm] |

Permissible Thrust [N] |

Permissible Speed [mm/s] |

Self-Locking Force [N] |

|---|---|---|---|---|---|

| NEW □30 |

2 | 50 | 40 | 30 | 40 |

| 100 | |||||

| 9 | 150 | 40 | 135 | 0 | |

| 200 | |||||

| □42 | 2 | 50 | 100 | 30 | 100 |

| 100 | |||||

| 12 | 200 | 100 (~80 mm/s) | 80 | 0 | |

| 50 (~180 mm/s) | 180 | ||||

| 300 | 100 (~80 mm/s) | 80 | |||

| 50 (~180 mm/s) | 180 |

Self-Locking Force* is 100 N Max. (Frame size 42 mm, lead 2 mm). Load Holding is Possible

For load holding applications such as fall prevention or movement prevention due to its own weight.

*Self locking is a phenomenon in which the screw shaft stops moving due to friction when the nut is attempted to be moved from the outside.

- Reduced Heat Generation: Enables load holding in the non-excitation state, resulting in lower heat generation due to shorter excitation time

- Cost Reduction: Possible to reduce electromagnetic brakes for load holding (in the case of 2 mm lead)

Assembly is Easy Without Couplings. Equipment Can be Designed in Less Space and in Less Time

The mounting adapter for linear actuator saves space by reducing the number of parts and reduces adjustment time for assembly and mounting accuracy. Start-up of equipment is possible in a shorter time.

Watch Video: How to install "mounting adapter for linear actuator" and motor

Supports the Axial Load Directly

Adopts an axial bearing mechanism to directly support axial loads.

It’s a reliable mounting adapter for linear actuator.

Wear-Resistant Resin Nut Used

Backlash Change Amount for 12 mm Lead (Reference value)

A Wide Variety of Motors and Drivers for More Reliable Motion

Motors with additional functions such as those with encoders and electromagnetic brakes can be used in combination with drivers that enable low-vibration and low-noise driving.

The low-vibration drive contributes to reducing wear of the nut for the "mounting adapter for linear actuator" and extending the grease-up period.

Depending on the Motor Combination, Various Needs Can be Met.

●Combination With Flat 2-Phase Stepper Motor

- Can be installed in narrow spaces (selection must be made according to load conditions)

Total Length 41.1 mm*: □42 mm mounting adapter for linear actuator + □42 mm flat 2-phase stepper motor

- *Excluding the length of lead screw

●Combination With "Stepper Motor With Encoder"

- Improved equipment reliability through position monitoring and detection of position errors

- Reduced encoder assembly time

Motor Sizing Service by Dedicated Staff Available

The permissible thrust and permissible speed vary depending on motor combination. Calculate the permissible thrust according to the load conditions.

Oriental Motor also offers a service where our dedicated staff can select motors on customers' behalf.

Please download the product recommendation information sheet, fill it out, and submit it via the inquiry form.

Applications

Space saving of equipment is realized by reducing the number of parts such as couplings that connect motors and screws.

Watch Video: Application example (from 1 min. 10 sec.)

Syringe Pump (Vertical example)

Self locking enables load holding when power is turned off. (Product with 2 mm Lead)

Test Tube Transportation (Horizontal example)

Capable of positioning and transferring at 180 mm/s. (Product with 12 mm Lead)

Centering of the Substrate Transportation

Load Alignment of the Conveyor

Elevating and Lowering Axis of the Parts feed

Opening and Closing the Shutter of the Inspection Equipment

Product Line

| Mounting Adapter for Linear Actuator | Combination Motor | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Frame Size (mm) | Product Name | Lead (mm) | Stroke (mm) | Permissible Thrust (N) | Permissible Speed (mm/s) | Transportable Mass (kg) | Self-Locking Force*(N) | ||

| Horizontal | Vertical | ||||||||

| 30 | LA302C05 | 2 | 50 | 40 | 30 | 4 | 4 | 40 | 2-Phase/5-Phase Stepper Motors PKP Series Frame Size 28 mm |

| LA302C10 | 100 | ||||||||

| LA309C15 | 9 | 150 | 135 | 2 | 0 | ||||

| LA309C20 | 200 | ||||||||

| 42 | LA422C05 | 2 | 50 | 100 | 30 | 10 | 10 | 100 | 2-Phase/5-Phase Stepper Motors PKP Series Frame Size 42 mm |

| LA422C10 | 100 | ||||||||

| LA4212C20 | 12 | 200 | 100 (~80 mm/s) |

80 | 5 | 0 | |||

| 50 (~180 mm/s) |

180 | ||||||||

| LA4212C30 | 300 | 100 (~80 mm/s) |

80 | ||||||

| 50 (~180 mm/s) |

180 | ||||||||

- *Vibration may prevent self locking from being effective.

Narrow down Products