Brushless Motors

BXII Series

- Multifunctional Model Capable of Position Control

- Speed Regulation ±0.05 %

- For the Type with an Electromagnetic Brake, It Can Hold the Load During Vertical Operation

- Output Power 30 to 400 W

- Speed Control Range (2) 30 to 4000 r/min

Features | Brushless Motor BXII Series

Speed Control

Wide Speed Control Range 2~4000 r/min

- Achieved speed ratio of 1:2000.

- Suitable for applications that require constant torque from low to high speeds.

(30~4000 r/min at analog setting.)

Stable Motor Drive

Speed Regulation ±0.05 %

Reduces speed variation due to changes in the load (load fluctuation) and the change of ambient environment (changing ambient temperature, voltage fluctuation).

Flutter Characteristics Effective Value: Approx. 0.1 %

The effective value of the flutter characteristics, which represents speed fluctuations of motor rotation, is about 0.1 %. (Reference value at rated speed)

Even when rotating at a certain speed, there will be slight fluctuation in the actual speed around the target rotation speed. The speed fluctuations are known as flutter.

Supports Multi-Speed Operation with Up to 16 Speeds

Up to 16 points of operation data, such as operating speed and acceleration/deceleration time, can be set.

Position Control

Operation and Switch Up to 16 Data Points With Just I/O

You can set up to 16 points of operation data such as travel amount and operating speed.

Linking Multiple Operation Data

In addition to single data setting, you can also set linked operation, which combines multiple operation data.

- *Dwell time is the wait time until the next positioning operation starts.

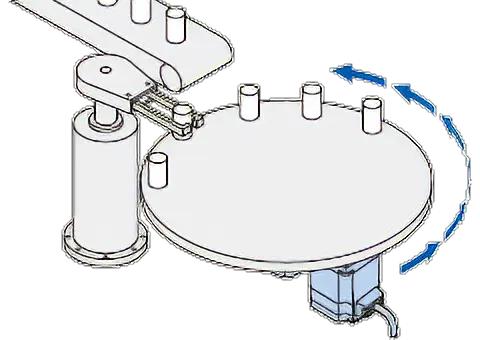

Continuous Rotation in the Same Direction is Possible

The command position and multiple rotation data can be returned to 0 if the command position exceeds the "wrap setting range" parameter value. Since the multiple rotation data is returned to 0, continuous rotation in the same direction is possible.

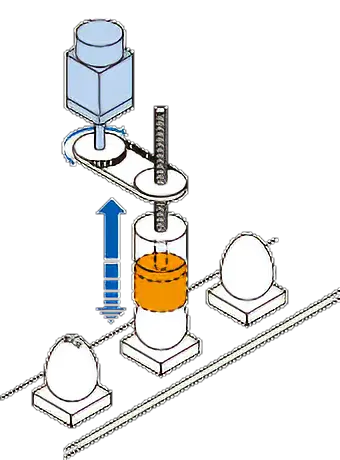

Vertical Operation and Position Holding

All models can be selected with or without an electromagnetic brake. The electromagnetic brake is automatically controlled to turn ON/OFF according to the operation command signal to the driver.

Capable of Vertical Operation (Gravitational operation)

With an electromagnetic brake, stable speed control is possible even when driving vertical operation.

During vertical operation, regenerative energy is generated. Use a regeneration resistor (Sold separately).

Capable of Position Holding When Stopped

Position holding when driving in a vertical direction* or horizontal direction is possible.

When driving horizontally, it is possible to set servo lock at motor standstill, which excites the motor to generate a holding force.

- *For vertical operation (gravitational operation), use a product with an electromagnetic brake.

Prevents Loads From Falling in an Emergency

The electromagnetic brake is of the power off activated type, so it works automatically even when power is lost in a blackout. Instantly stops the motor and prevents the load from falling.

Electromagnetic brake structure and service life|Technical reference

Torque Limiting Function

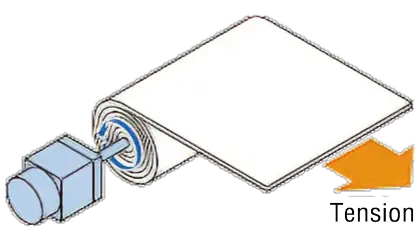

It can be used for applications that require adjustment of torque and tension, such as tension (brake), pushing (pressing), and tightening.

-

Tension - As a Brake to Gain Tension

-

Pushing - For Printing and Other Press Applications

The setting range of the maximum instantaneous torque of the motor can be limited from 0 to 250 % in 1 % units.

- Torque limiting accuracy ±10 % approx. (relative to rated torque)

- Torque limiting can be switched ON/OFF with an external signal (TL input)

Support Software, Monitoring Function

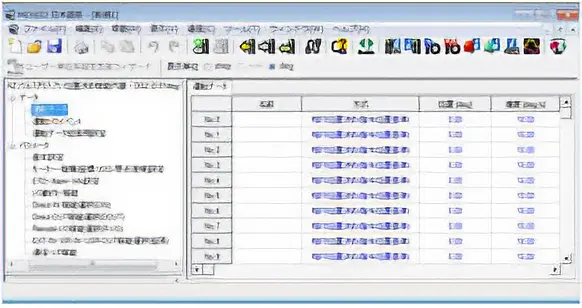

Easy Setting and Start-Up With MEXE02 Support Software

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Click here to download the support software

Comprehensive Support From Start-Up to Maintenance With a Variety of Functions

-

Startup and Evaluation

Useful functions for wiring check and test operation are provided.

- Setting and Saving of Operation Data

- I/O Monitor

- Teaching, Remote Operation

-

Adjustment

The following functions are available to help you adjust motor operation after the equipment is installed.

- Waveform Monitor

-

Diagnosis and Maintenance

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitor

- Status Monitor

- Warning Monitor

-

Operation Data/Parameter Setting Screen -

Waveform Monitor

On-Site Monitoring and Troubleshooting are Also Possible

Speed and alarm information can be monitored on the driver's display screen. Data setting and test operation are also possible at the operation panel.

-

[Alarm code indication] -

[Load factor indication]

If the OPX-2A control module is connected, operation becomes even easier.

Reduction of Installation Space

Compact Driver for Close Installation to Reduce Installation Space.

Optimized arrangement of internal parts has made the drivers compact and slim. It also supports close installation of multiple units, further reducing installation space.

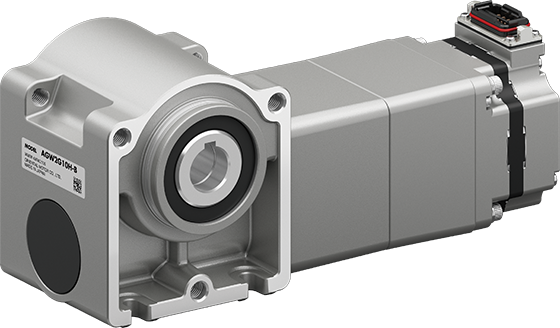

Gearhead Type

Gearhead Type

| Gearhead Types | Parallel Shaft Gearhead | Hollow Shaft Flat Gearhead |

|---|---|---|

| GFS Gearhead | FR Gearhead | |

| External View |  |

|

| Features |

|

|

| Output Power | 30 W, 60 W, 120 W 200 W, 400 W |

30 W, 60 W, 120 W 200 W, 400 W |

| Gear Ratio | 5~200 | 5~200 |

| Rated Life | 10000 hours | 10000 hours |

| Permissible Radial Load* | 1400 N | 2040 N |

| Permissible Axial Load* | 400 N | 800 N |

| Permissible Torque* | 70 N·m | 54 N·m |

- *This value is for output power of 200 W, 3000 r/min, and the maximum gear ratio.

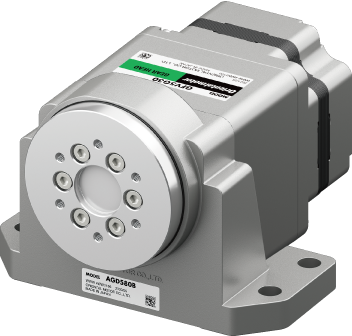

Worm Gearhead/Flange Drive Adapter With Even More Torque and Load

-

Significantly Increased Permissible Torque

Worm Gearhead (Sold separately)Applicable Motor: Brushless motor, parallel shaft gearhead, 30 W

- Permissible torque is approximately 3 times that of parallel shaft gearheads

- For load holding applications that require self locking to prevent collapsing under its own weight

- Space saving with right-angle shaft/hollow shaft

Refer to here for more information.

-

Dramatic Increases in Permissible Load

Flange Drive Adapter (Sold separately)Applicable Motor: Brushless motor, parallel shaft gearhead 100 W/120 W

- Flat profile and high permissible load (permissible radial load/permissible axial load)

- For heavy load transfer applications such as automated guided vehicles and rotary tables

- Direct mounting to load shafts and enclosures reduces design effort

Refer to here for more information.

Product Line

The motor, driver, and connection cable can be purchased individually.

Note

The motor cable and the encoder cable from the motor cannot be connected directly to the driver.

Be sure to purchase a connection cable or flexible connection cable.

| Output Shaft Type*1 | Frame Size [mm] |

Rated Output Power [W] |

Gear Ratio | Rated Voltage [V] |

Connection Cable*2 |

|---|---|---|---|---|---|

|

60 | 30 | 5~200 | Single-Phase 100-120 Single-Phase, Three-Phase 200-240 |

Connection Cable

|

| 80 | 60 | ||||

| 90 | 120 | ||||

| 110 | 200 | ||||

| 400 | Single-Phase, Three-Phase 200-240 | ||||

|

60 | 30 | 5~200 | Single-Phase 100-120 Single-Phase, Three-Phase 200-240 |

|

| 80 | 60 | ||||

| 90 | 120 | ||||

| 104 | 200 | 10~100 | |||

| 400 | 5~100 | Single-Phase, Three-Phase 200-240 | |||

|

60 | 30 | - | Single-Phase 100-120 Single-Phase, Three-Phase 200-240 |

|

| 80 | 60 | ||||

| 90 | 120 | ||||

| 104 | 200 | ||||

| 400 | Single-Phase, Three-Phase 200-240 |

- *1

- Models with an electromagnetic brake are available for all types.

- *2

- A set of cables for motor and encoder.

Related Products

Brushless Motors

BLE2 Series

- Multifunctional model with 4 selectable data setting methods

- Torque limited, 16-speed operation

- For the type with an electromagnetic brake, it can hold the load during vertical operation

- 30~400 W, 80~4000 r/min

Brushless Motor

BMU Series

- Easy "Rotate-and-Push" Operation

- 4-Speed Operation

- Easy Wiring

- 30~400 W, 80~4000 r/min

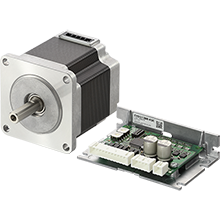

Stepper Motors

PKP Series/CVD Series SC Type Driver

- Easy control with forward/reverse input

- two-speed operation

- 0.02~600 r/min

Narrow down Products