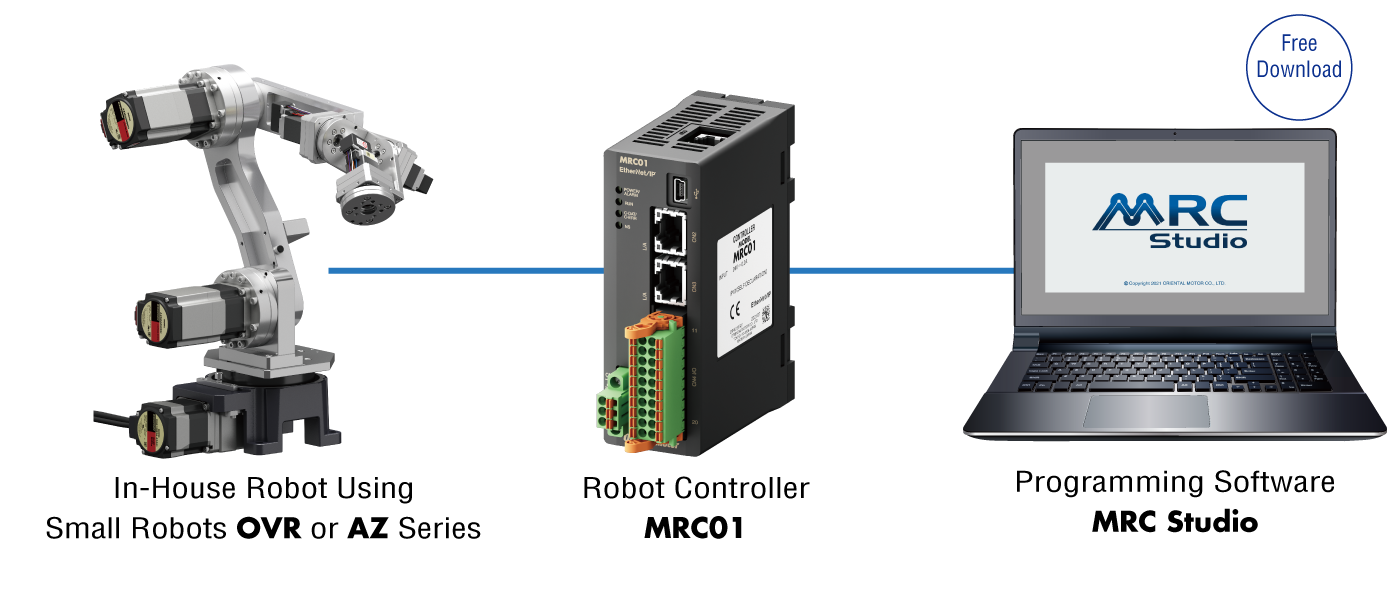

Robot Controller

MRC01

- Easy Introduction and Control of Robots

- Easy Setup with Programming Software

- Vertical/Horizontal Articulated, Cartesian Robot Control Possible

Features | Robot Controller MRC01

- Easy Operation for Machine Designers With No Experience in Sequence Control Using PLCs

- Easy Introduction of Robots Into Existing Systems

- Easy Setup With the Robot Controller MRC01 and the Programming Software MRC Studio

- Linkage Function With 2D Camera to Automate More Advanced Operations

- Multiple User Coordinate Systems (Load coordinating system) Can be Set

- MRC Studio Simulator (Free of charge) Allows You to Check the Robot's Operation During the Pre-purchase Review Phase

- Can be Combined With AZ Series Products/AZ Series Equipped Electric Actuators

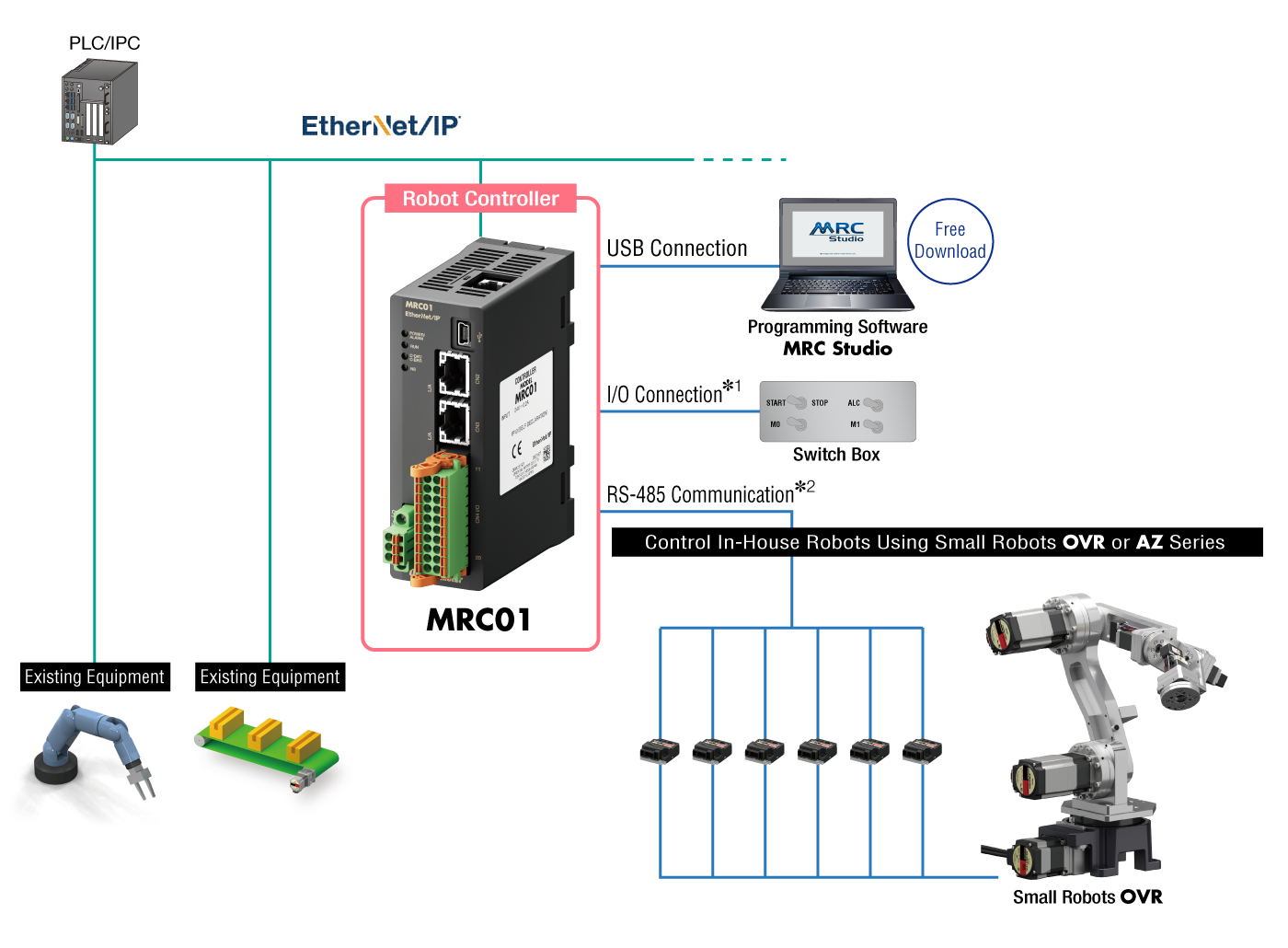

Easy Operation for Machine Designers With No Experience in Sequence Control Using PLCs

The MRC01 can easily teach and check operation programs set up with the MRC Studio programming software using only a PC.

Easy Introduction of Robots Into Existing Systems

MRC01 links to the host controller using EtherNet/IP™ for direct control. You can easily introduce Small Robots OVR or in-house robots without making significant changes to the control system for existing equipment.

- *EtherNet/IP™ is a trademark of ODVA.

- *1

- The MRC01 can also be operated with an I/O connection (without a host controller).

- *2

- The MRC01 and AZ Series driver are controlled by RS-485 communication.

Easy Setup With the Robot Controller MRC01 and the Programming Software MRC Studio

The "MRC Studio programming software" is available for easy setup of in-house robots from initial settings to operation programming.

The "MRC Studio Simulator" that enables teaching without communication with the MRC01 is also available. Programs created with MRC Studio Simulator can be used without change when installing actual robots.

Both software packages are available for free download.

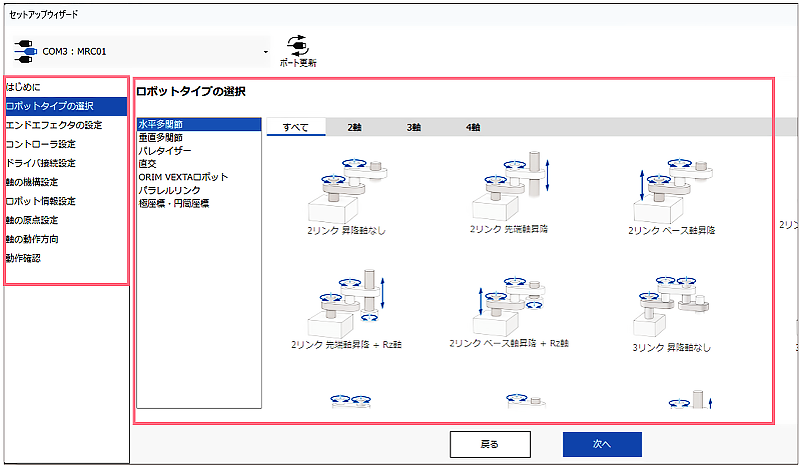

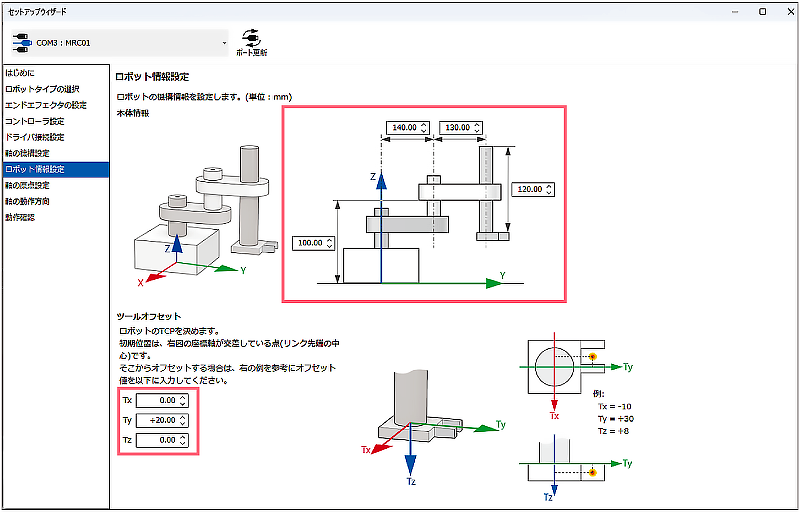

Step 1. Follow the Guide to Complete Initial Settings without Getting Lost.

The wizard provides guidance for carrying out a variety of initial settings such as robot type selection and mechanism information input. By following the directions and illustrated instructions, even first-time users can complete the initial settings for robots in a short time.

Follow the Steps to Set Up

Follow the wizard menu to proceed with the initial setup of the robot.

Input Arm Length and Other Dimensions While Looking at the Illustration of the Robot

Dimensions are entered directly in the input boxes in the illustration.

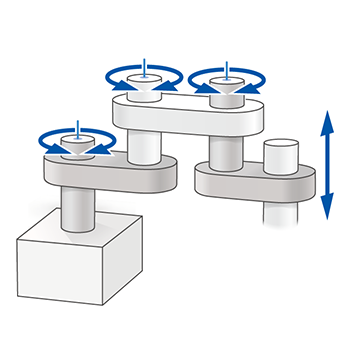

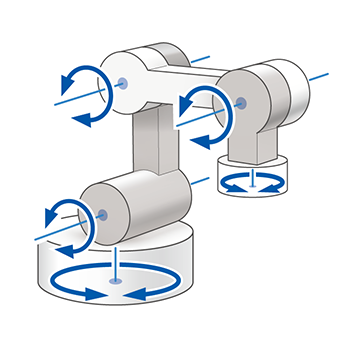

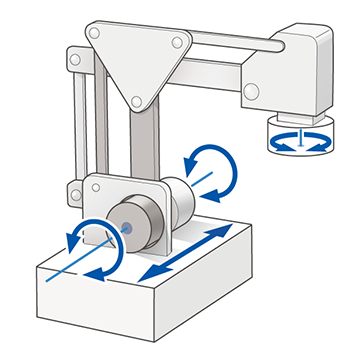

Select Robot Type

(Typical example)

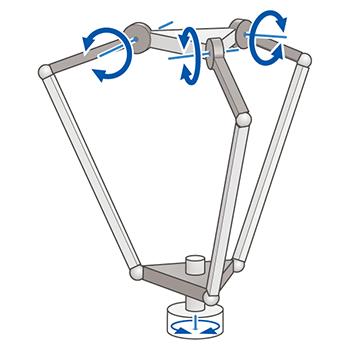

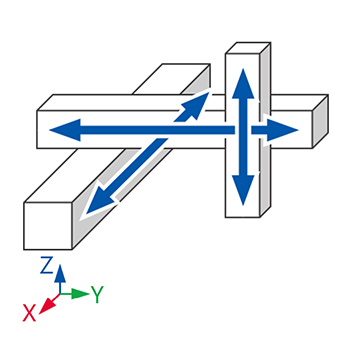

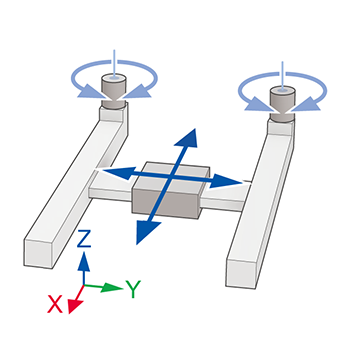

| SCARA | Articulated | Palletizer | Parallel Link |

|---|---|---|---|

|

|

|

|

| 3-link tip up-down | 3-link base rotation + Rz | 2-link mechanism base linear motion + Rz | Parallel link + Rz |

| Cartesian | Small Robots OVR Articulated |

Small Robots OVR SCARA |

|

|---|---|---|---|

|

|

|

|

| XYZ | Planar surface gantry (XY) | OVR6048K1-V (6 axes) | OVR3041K3-H (3 axes) |

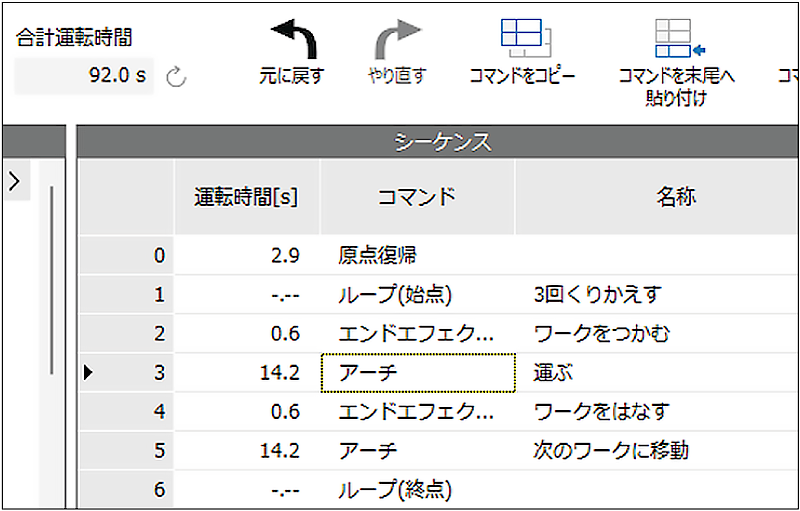

Step 2. Knowledge of Ladders not Required. Program operations by selecting items.

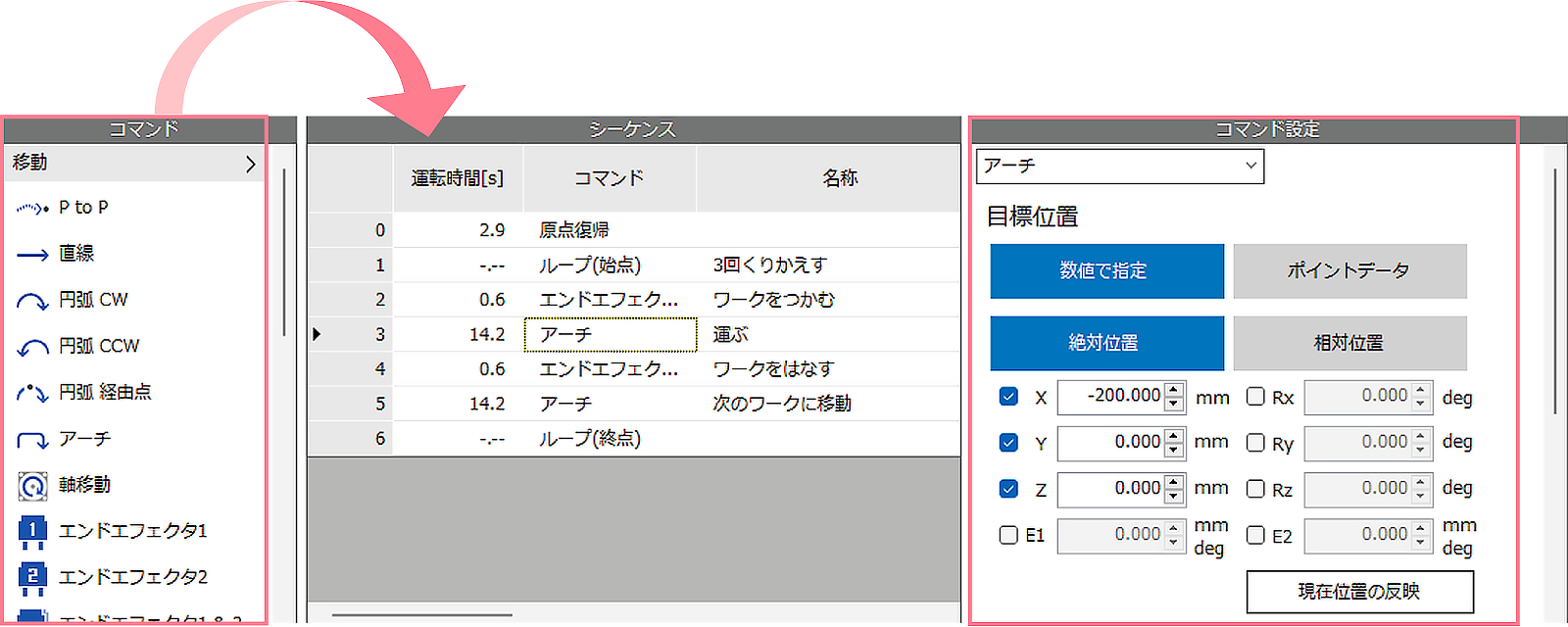

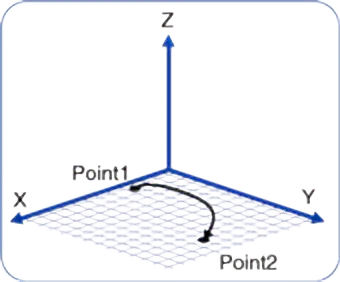

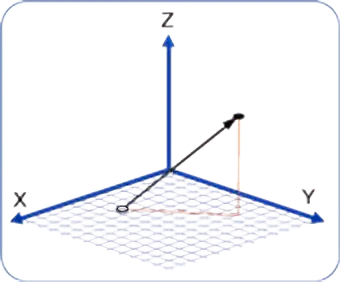

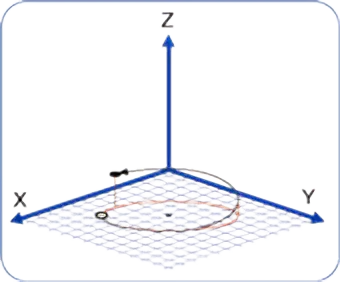

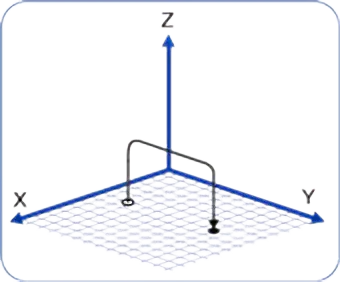

Simply select commands to create a program. Programs can be created intuitively without specialized knowledge such as ladders. Compatible with a variety of operations, such as P to P, linear interpolation, circular interpolation, and arch motion. In addition, direct operation data operation can also be performed via EtherNet/IP from the host controller.

Drag and drop the necessary commands

Select the desired action from the "Command" column and drag and drop it into the "Sequence" column to display the "Command Settings" column.

Set target position and speed

Specify the coordinates and travel distance of the target position and enter the speed in the command setting field.

| Command | ||||

|---|---|---|---|---|

|

|

|

|

|

| P to P Control | Linear Interpolation | Circular Interpolation (Helical interpolation) | Arch Motion | Palletizing |

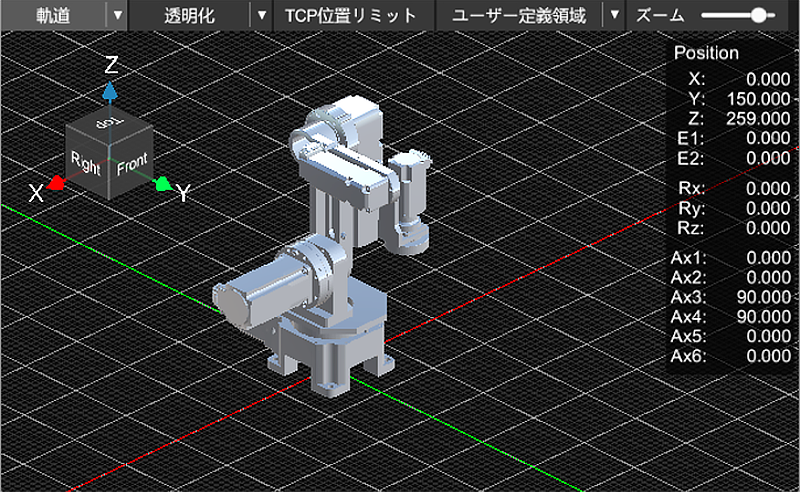

Step 3. Operation Confirmation Using an Online 3D Simulator

The program operation time can be displayed and the program contents can be verified considering the robot's moving range, etc.

It is possible to check the operation on 3D graphics without moving the actual device.

- *There may be differences between simulation and actual operation.

- *Simulation requires communication with MRC01.

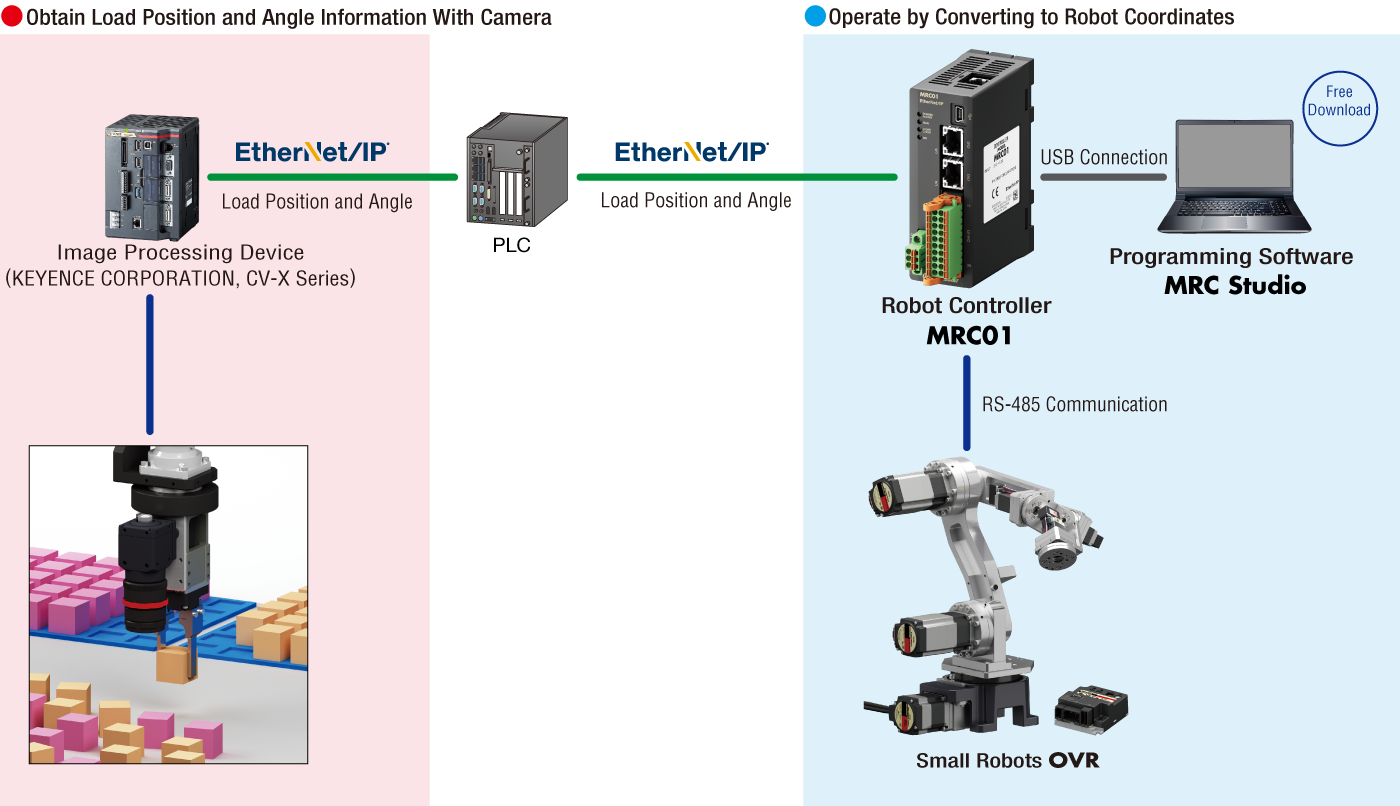

Linkage Function With 2D Camera to Automate More Advanced Operations

Building a Robot Vision System Using a 2D Camera

The robot controller MRC01 is equipped with useful functions for driving the robot using information on the position and angle of the load acquired by the camera.

About Compatible Models of Image Processing Equipment and PLCs

The above configuration diagram is an example of connection with the CV-X Series manufactured by KEYENCE CORPORATION. Other compatible models will be released on our website as they become available.

About Calibration

In order to work with a 2D camera, the camera is pre-calibrated using MRC Studio. The settings can be easily configured by simply following the on-screen instructions while looking at the illustrations, reducing the man-hours required for correction. (Up to 2 cameras can be calibrated.)

Application Example

There are many automations that can be realized by linking with a 2D camera, such as load position information detection, dimensional and visual inspection, etc. Here is an example.

Position Correction

Alignment of cumbersomely arranged loads (fixed camera method)

Color Recognition

Sorting loads of different colors (hand-eye method)

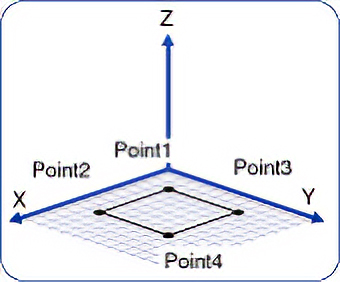

Multiple User Coordinate Systems (Load coordinating system) Can be Set

This is useful when the same work is repeated in multiple work areas. It is possible to change the starting point of work without changing the operation program.

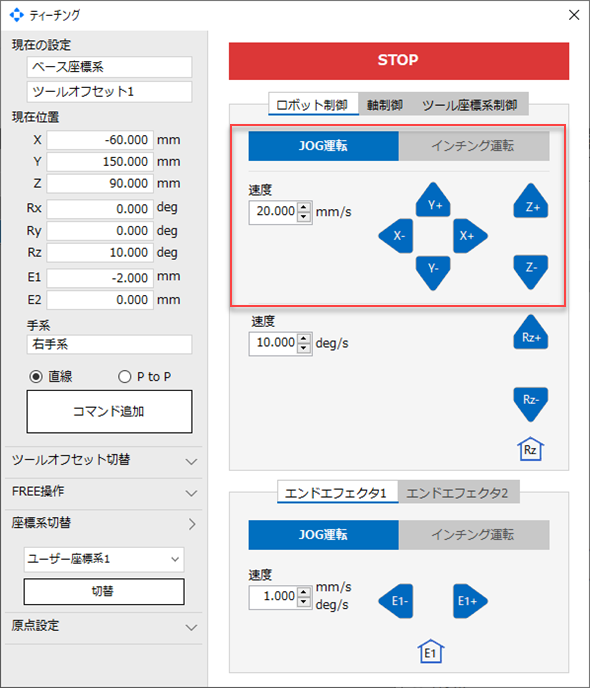

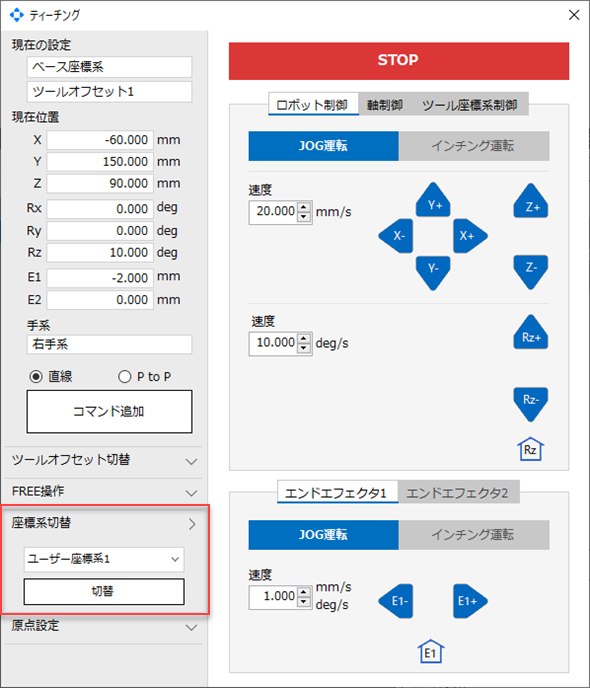

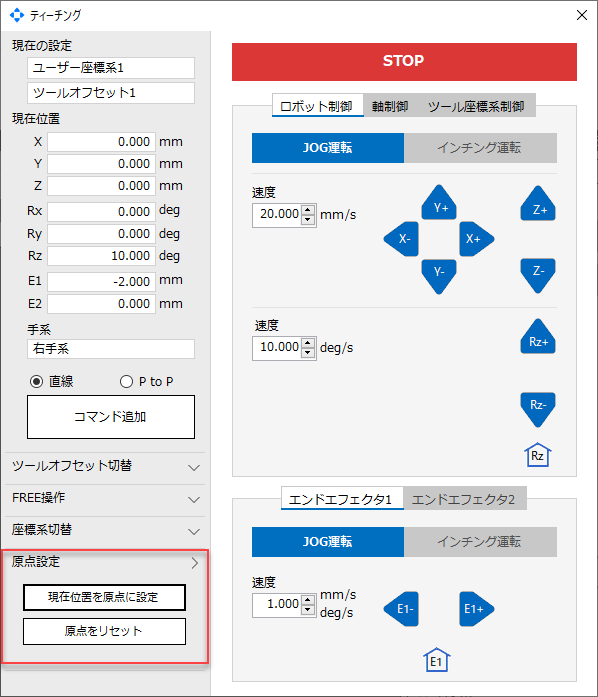

Coordinate System is Set From Teaching Screen

Up to 3 arbitrary positions can be set as the origin. Settings are made from the MRC Studio teaching screen.

-

Move the robot to the position to be set as the origin -

Select coordinate system -

Set the current position as the origin

Easy Switching Within a Single Program

The coordinate system can also be changed by the coordinate system switching command in the operation program. Multiple coordinate system switching commands can be added to a single program.

MRC Studio Simulator Allows You to Check the Robot's Operation During the Pre-purchase Review Phase

MRC Studio Simulator is software that enables simulation of actual movements without the robot itself or the MRC01.

Operation programs created with MRC Studio Simulator can be used without change when installing actual robots.

Differences Between MRC Studio Simulator and MRC Studio (Product version)

Both are available for free download. The differences in functionality are as follows.

| Item | MRC Studio Simulator | MRC Studio (Product version) |

|---|---|---|

| Communication with the robot controller MRC01 | - | ○ |

| Setup | △ | ○ |

| Items that communicate with the robot controller MRC01 or the driver cannot be set. | ||

| Save configuration data file to PC | ○ | ○ |

| Open file | ○ | ○ |

| Open the .mrcxt file. A sample file of the configuration program is also available. |

Open the .mrcx file. | |

| Import data files created with MRC Studio Simulator | - | ○* |

| Teaching | ○ | ○ |

| Operation program creation | ○ | ○ |

| Test operation | ○ | ○ |

| Parameter setting | △ | ○ |

| Some parameters cannot be set. For more information, please refer to [Help] → [See How to Use] in MRC Studio Simulator. |

||

| Monitoring | △ | ○ |

The following can be monitored.

Information on signal systems that require connection to external devices cannot be monitored. |

- *The MRC Studio Simulator does not take into account the load condition of each axis, which may cause differences in actual operation.

When operating the actual device for the first time, we recommend that you try a lower operating speed rate.

Combination Products

In addition to the Small Robots OVR, it can be combined with the AZ Series and electric actuators equipped with the AZ Series.

Small Robots OVR

AZ Series

Electric Actuators

Electric Linear Slide EZS Series

For Clean Room Use

Narrow down Products