Equipped with Built-in Battery-Free Absolute Encoder

αSTEP AZ Series

- Equipped with Built-in Battery-Free Absolute Encoder

- AC/DC Input

- Industrial Network Compatible

- Wide Speed Range and Torque Band

Right-angle FC geared type with frame size 35 mm has been added to the cable type motors.

Features | αSTEP AZ Series

Equipped with ABZO sensor

Newly Developed ABZO Sensor

This is the battery-free mechanical absolute encoder. This can help improve productivity and reduce costs.

Both motor and driver are available at reasonable prices.

Mechanical-Type Sensor

The ABZO Sensor is equipped with multiple gears and detects position information by recognizing the angle of individual gears.

As a result, it does not require a battery.

Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 revolutions (1800 revolutions) of the motor shaft from the reference home position.

- *±450 revolutions (900 revolutions) for products with 20 mm, 28 mm (30 mm) frame size.

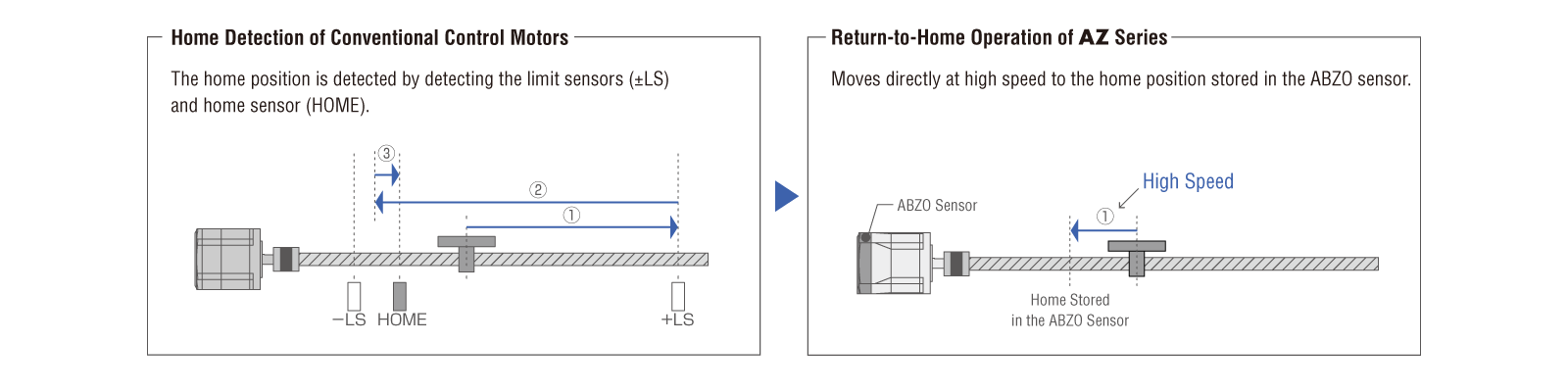

No External Sensors Required

As it is an absolute system, external sensors such as a home sensor or limit sensor are not required.

Improved High-Speed Return-to-Home + Return-to-Home Accuracy

Return-to-home can be performed without home sensor or limit sensor. It reduces machine cycling, achieving high speed return-to-home without worrying about sensor sensitivity. At the same time, variations in the home position due to sensor sensitivity will no longer occur. It improves home accuracy.

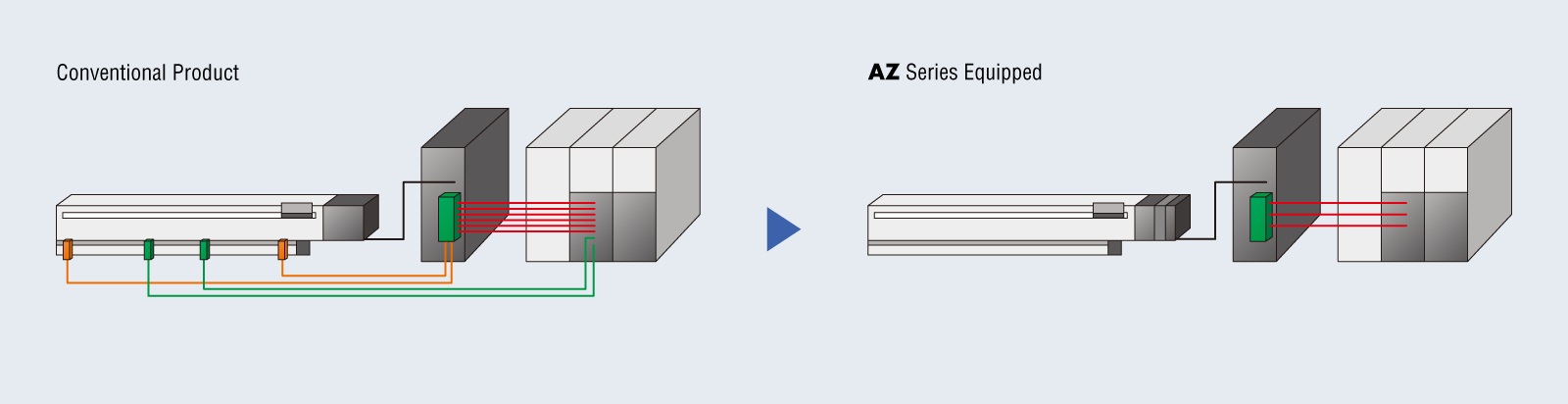

Reduced Cost

Does not incur external sensor or wiring costs. It reduces the cost of the entire system.

Increased Flexibility in Designing Equipment

Saves space that was previously required to install and wire external sensors. It improves the flexibility of equipment designs.

Not Affected by External Sensor Malfunctions

Eliminates malfunctions, failures, and disconnection of external sensors, which can occur in environments where metal chips may fly when machining metal, or oil mist is present.

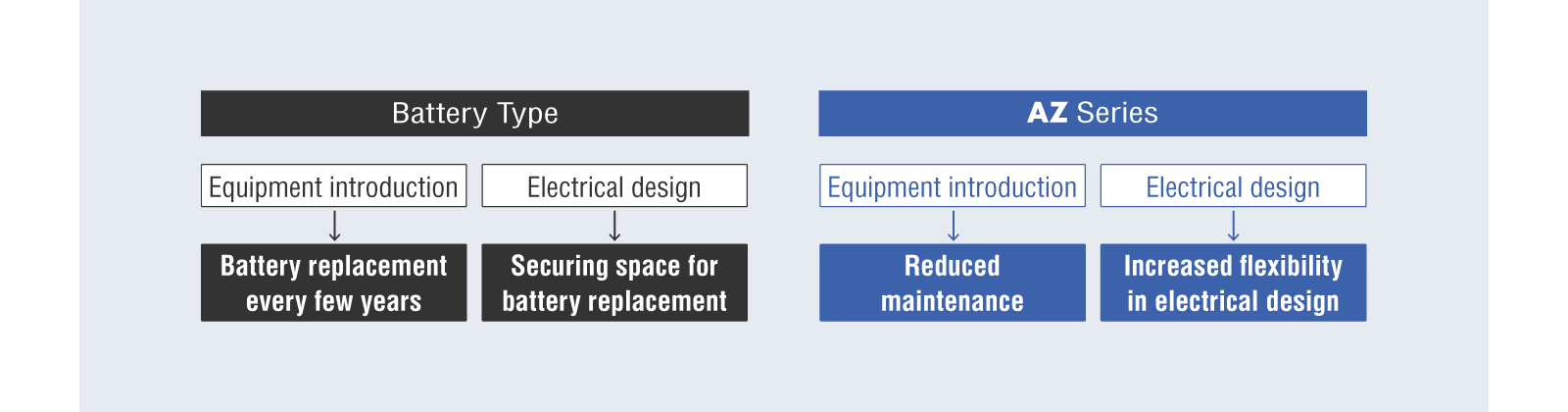

Battery-Free

Mechanical-type sensors do not require batteries. Manages position information mechanically.

Holding Positioning Information

Position information is retained even if the power is interrupted or the cable between the motor and driver is disconnected during positioning operation.

Reduces the time required for return-to-home operation.

Reduced Maintenance

No need to replace batteries. Reduces maintenance time and costs.

More Flexibility in Driver Installation

Saves space that was previously required to install batteries and wiring. There are no restrictions on driver installation locations, improving design flexibility for the layout of control cabinets, etc.

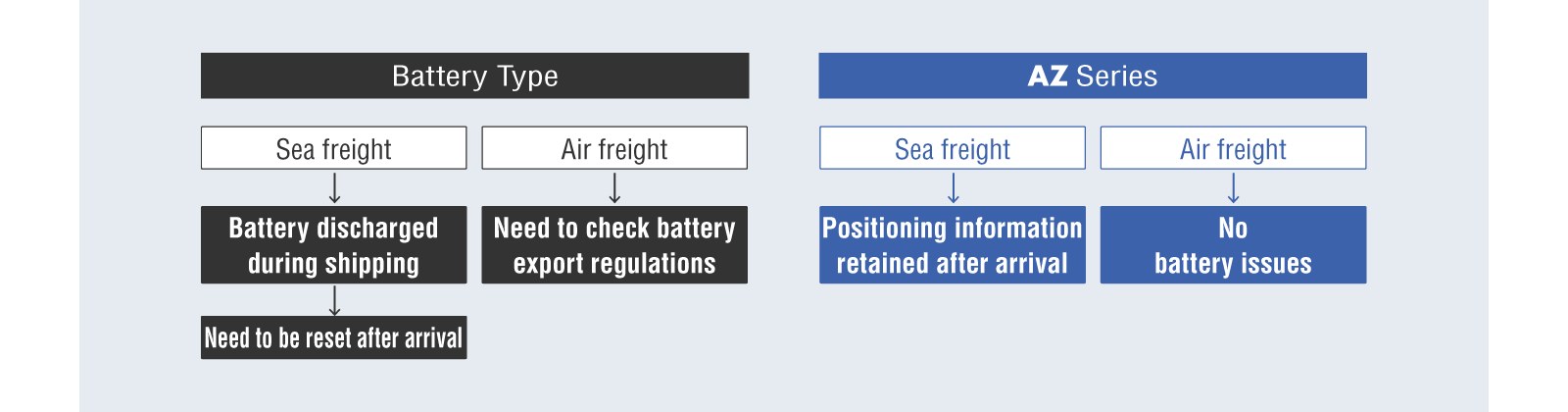

Safe for Overseas Shipping

As batteries will self-discharge, care must be taken when the equipment requires a long transportation time, such as when being sent overseas. The ABZO Sensor has no limit for how long position information is saved. In addition, there is no need to consider the various regulations applicable when exporting batteries overseas.

Power saving and low heat generation

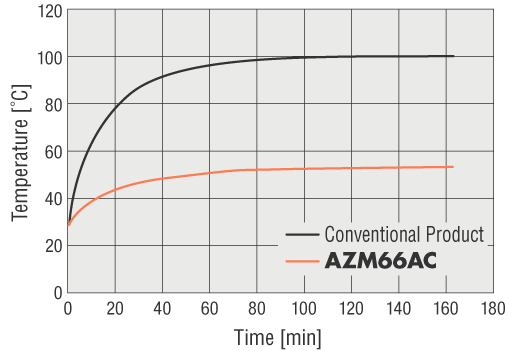

Significantly Reduced Heat Generation

-

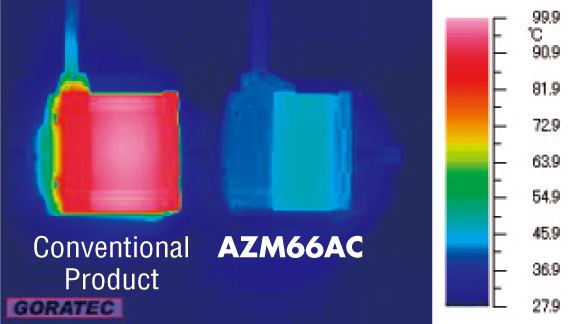

Temperature Distribution by Thermography

This is an example of operation under the same conditions. -

Motor Surface Temperature During Operation Under the Same Conditions

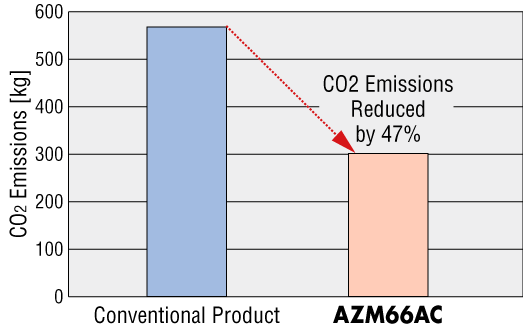

Power Consumption Reduction via Energy Savings

-

AC Input

Power Consumption and CO2 Emissions are reduced by 47% compared to the conventional products (compared to our products)

Operating Condition

-

- Rotation Speed

- 1000 r/min

-

- Load Factor

- 50 %

-

- Operation Time

- 24-hour continuous operation, 365 days a year

-

- Operation Status

- Operation 70 %, Standby 25 %, Stop 5 %

-

- Power Supply Voltage

- Single-Phase 200-240 VAC

-

- CO2 Coefficient

- 0.519 kg-CO2/kWh

-

-

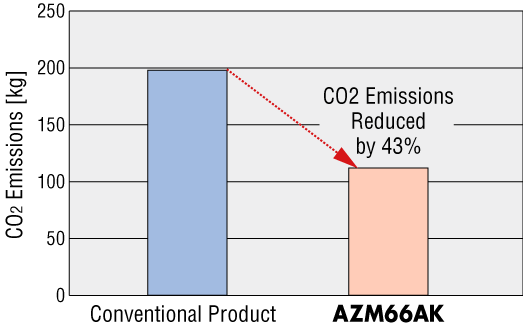

DC Input

Power Consumption and CO2emissions.43% reduction from the previous level(compared to Oriental Motor)

Operating Condition

-

- Rotation Speed

- 1000 r/min

-

- Load Factor

- 50 %

-

- Operation Time

- 24-hour continuous operation, 365 days a year

-

- Operation Status

- Operation 70 %, Standby 25 %, Stop 5 %

-

- Power Supply Voltage

- 24 VDC

-

- CO2 coefficient

- 0.519 kg-CO2/kWh

-

Fusion of closed-loop and open-loop, stable and fast even without adjustment

Driven by Open Loop Control in Normal Operation, Closed Loop Control in Overload Operation

The system is driven by open loop control during normal operation, which offers a variety of advantages.

In case of overload, the system automatically switches to closed loop control to prevent abnormal shutdown.

Advantages of Open Loop Control

Moves in Sync With Commands Without Gain Adjustment

Even mechanisms with low rigidity, such as a timing belt, can follow commands without adjustment.

Runs in Sync With Commands Even if Load Conditions Change

Even mechanisms with large load fluctuations, such as cams, can follow commands without adjustment.

No Hunting

It can also be used safely in applications where slight vibration at motor standstill may be a problem.

Advantages of Closed Loop Control

In case of overload, the motor is controlled to maximize torque. Avoid problems such as motor stoppage due to insufficient torque.

Full Range of Monitoring Functions

Sensors are mounted on the motors so that position and speed information can be constantly monitored.

It also includes a "positioning completion signal" that is useful for monitoring the operating status.

Types and features of motor geared type

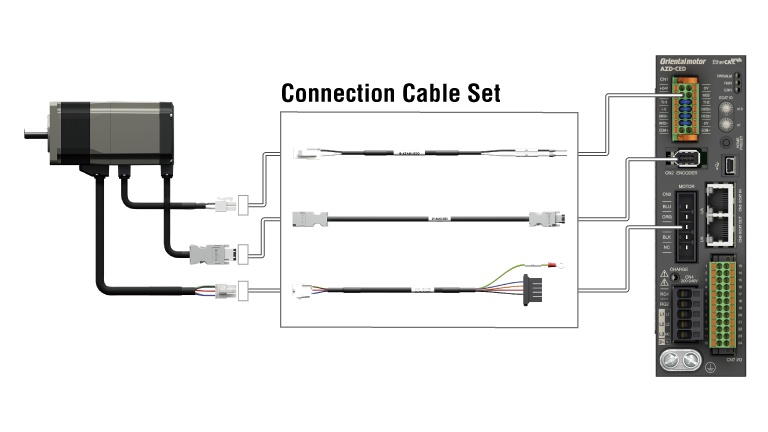

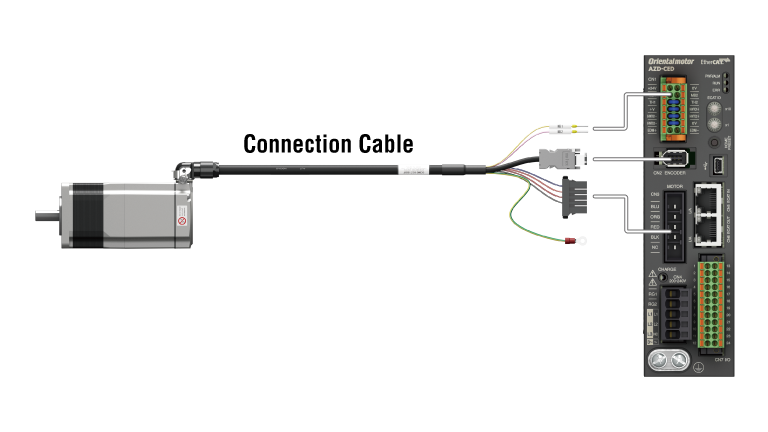

Two Connection Methods Are Available for Motors

|

Cable Type Relay and connect with multiple cables |

Connector Type Direct connection with a single cable Click here for features and advantages of connector type |

|---|---|

|

|

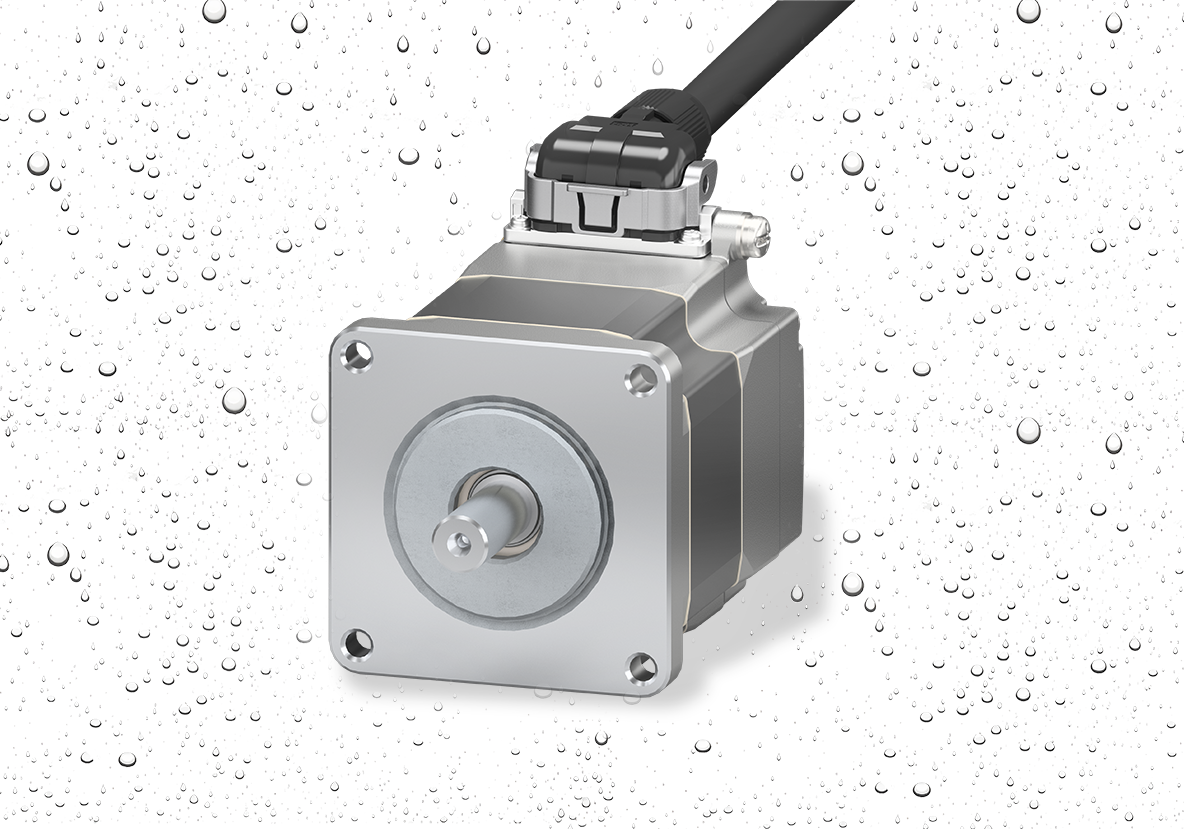

Degree of Protection IP66 Rating (Connector Type)

With a degree of protection IP66 rating, it has a high dust-resistant performance and can be used in an environment where water droplets may splash on it.

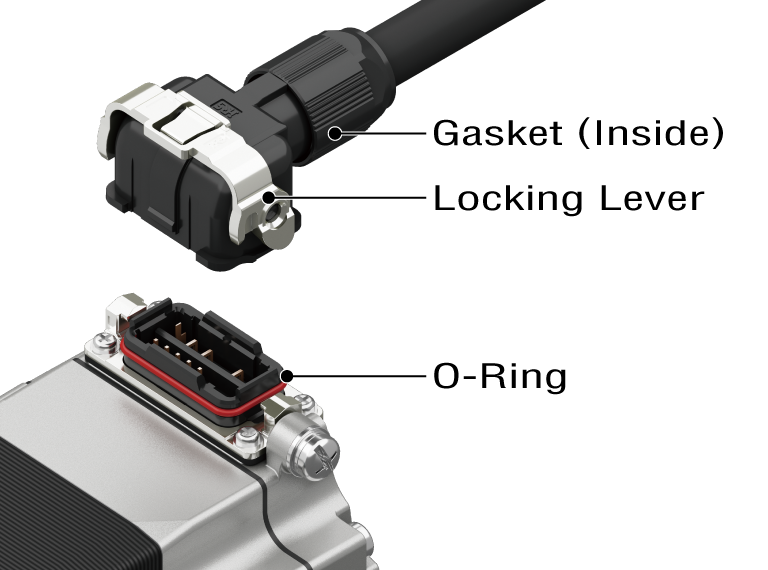

Connector Structure

The connector structure has a built-in gasket and O-ring for improved waterproofing. It is IP66-compliant, including the connector part.

Types and Features of Geared Type

In addition to high torque and high resolution, various advantages such as the ability to drive large inertial loads can be obtained.

Click here to see the advantages of geared type

| Type | Features | Frame Size [mm] |

Backlash [arcmin] |

Resolution (Resolution Setting: 1000 P/R) [o / Pulse] |

|

|---|---|---|---|---|---|

| TS geared |

|

|

42~90 | 10~45 | 0.012~0.1 |

| Right-Angle Shaft FC Geared |

|

|

35, 42, 60 | 10~40 | 0.012~0.05 |

| PS Geared |

|

|

28~90 | 7~35 | 0.0072~0.072 |

| HPG Geared |

|

|

40~90 | 3 | 0.024~0.072 |

| Harmonic Geared |

|

|

30~90 | 0 | 0.0036~0.0072 |

Driver Product Line and Features

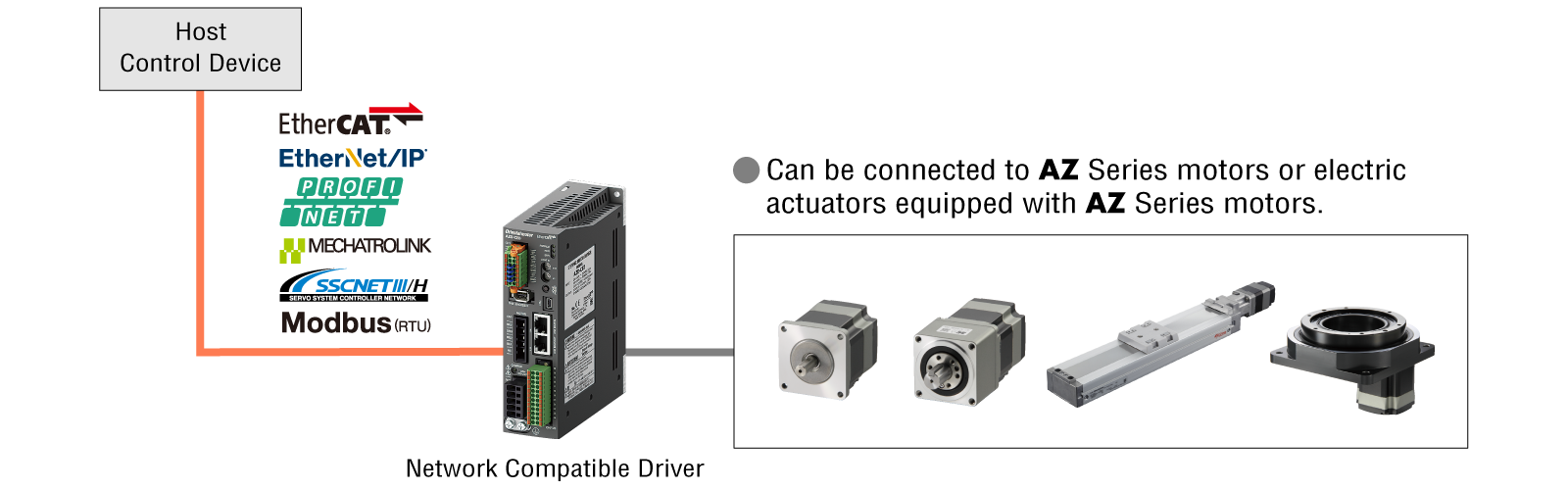

Network Compatible Driver

Compatible with all major industrial networks used around the world, contributing to centralized management of equipment information and reduced wiring. AC Input Driver is superior to DC Input in terms of torque, and DC Input Driver is compact in comparison to AC Input. Find for the purpose and application.

-

AC Input -

DC Input

|

|

|

|

| EtherCAT Compatible | EtherNet/IP Compatible | PROFINET Compatible |

| AC Input DC Input |

AC Input DC Input |

AC Input DC Input |

|

|

|

|

| MECHATROLINK-III Compatible | SSCNET III/H Compatible | Built-In Controller Type |

| AC Input | AC Input | AC Input DC Input |

- *The Built-In Controller Type can be controlled by CC-Link using Network Converters (gateway) sold separately.

Provides information on how to connect and set up when combining Oriental Motor products with other companies' products.

This is useful for designing programs and equipment startup.

Mini Driver (DC input only)

Mini driver designed to be more compact and lightweight than a single axis driver. Can be installed even in a small space. Due to the wide voltage specifications that can be used with the battery power supply, it is also suitable for incorporation into self-propelled equipment.

EtherCAT Compatible

EtherNet/IP™ Compatible

PROFINET Compatible

Ethernet Type

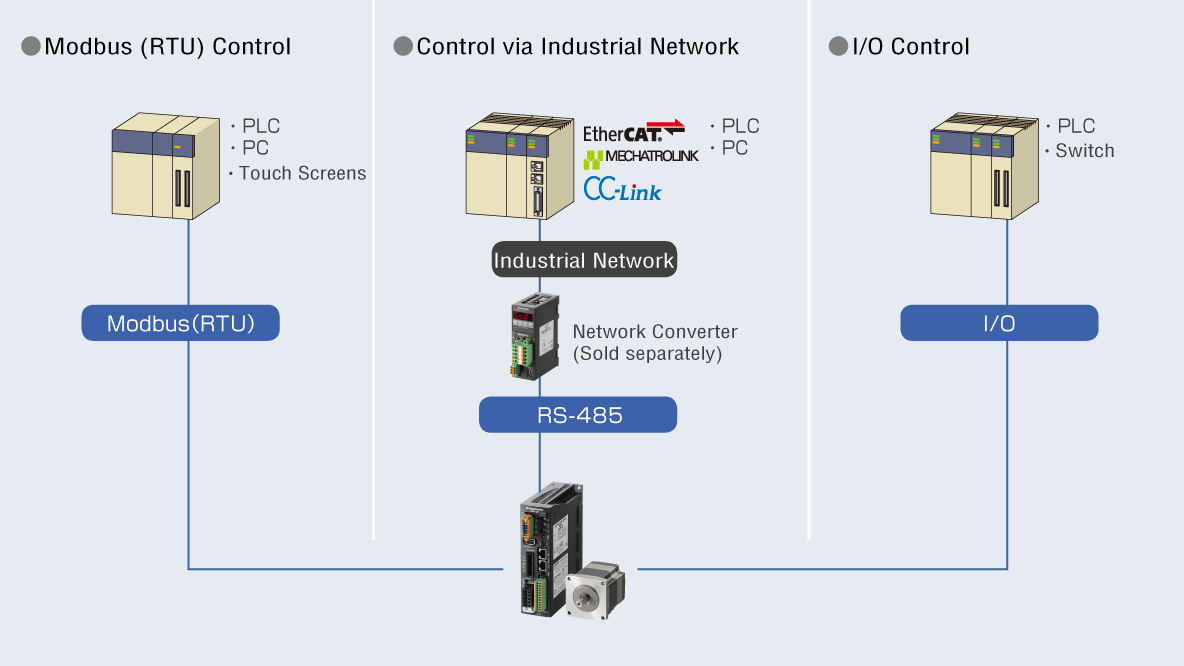

RS-485 Communication Type

Pulse Input Type With RS-485 Communication

- *The RS-485 communication type can be controlled by CC-Link and MECHATROLINK using a Network Converter (gateway) sold separately.

Multi-Axis Driver (DC input only)

Multi-Axis driver that can control multiple axes (up to 4 axes) with 1 driver. Connection to a host network or power supply is integrated into a single driver, contributing simple wiring, space saving, and cost saving.

-

2-Axis Type -

3-Axis Type -

4-Axis Type -

NEW

Slim Type (4-Axis) -

- For more details about the Slim Type, please contact your nearest branch, sales office, or Customer Support Center.

Built-In Controller Type

- Operation data such as "position" and "speed" are set to the driver, and the I/O module selects and executes the operation data. Up to 256 points of operation data can be registered.

- Can be controlled by either I/O, Modbus (RTU) or Network Converters (gateway). When used together with a network converter, it can be controlled by CC-Link, EtherCAT, and MECHATROLINK.

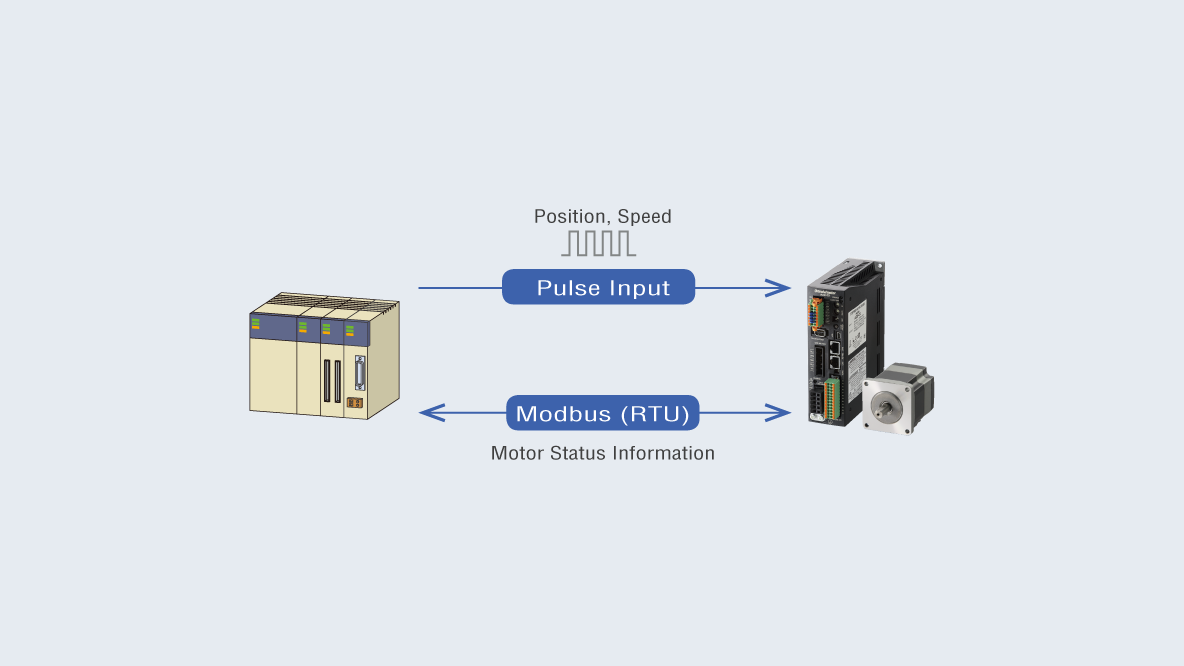

Pulse Input Type With RS-485 Communication

Executes operation according to pulse signal input to Driver. Controlled by positioning module (pulse generator), etc. Allows monitoring of motor status information (position, speed, alarm, etc.) in RS-485 communication.

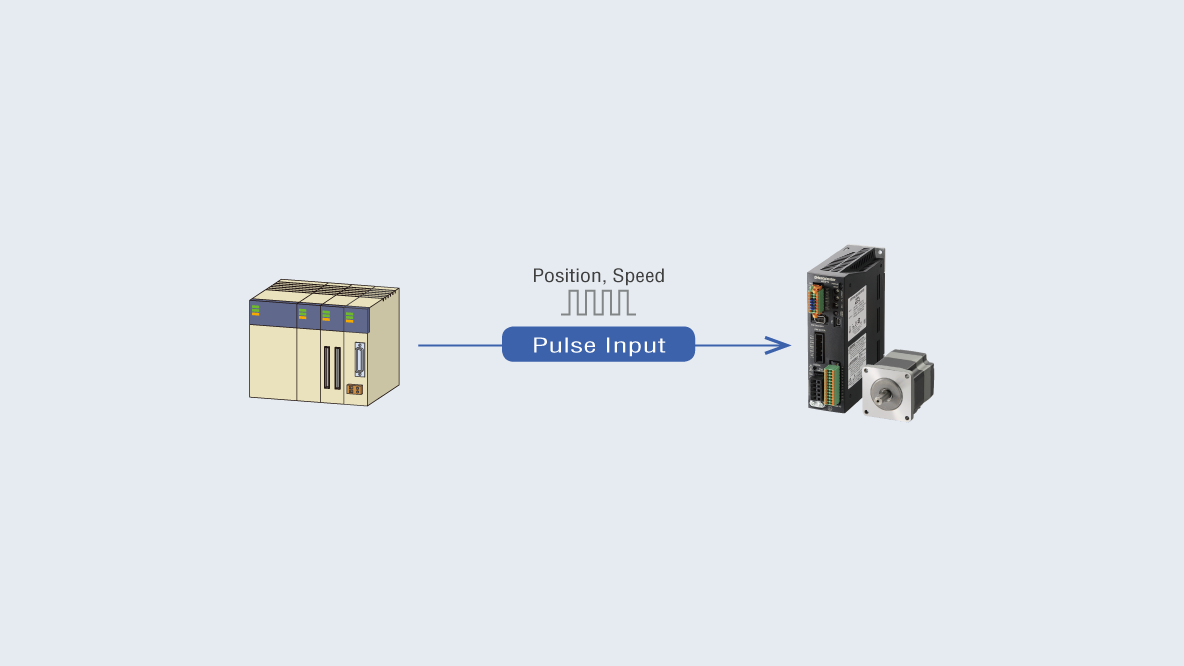

Pulse Input Type

Executes operation according to pulse signal input to Driver. Controlled by positioning module (pulse generator), etc.

Acquisition of "Functional Safety" Certification

Obtaining "Functional Safety *" certification has made it easier to support safety systems. Reduces accessories, simplifies wiring, and makes for a space saving system.

- *STO (Safe Torque Off) function equipped

SIL 3, PL e Functional Safety Certification Obtained

| Applicable Standards | Safety Level |

|---|---|

| IEC 61800-5-2, EN 61800-5-2 | SIL 3 |

| IEC 61508-1, EN 61508-1 | |

| IEC 61508-2, EN 61508-2 | |

| ISO 13849-1, EN ISO 13849-1 | PL e (Category 3) |

Introduction to Advantages of Certified Products and Applications

Applicable Products

αSTEP AZ Series AC Input Driver

- EtherCAT Compatible

- EtherNet/IP™ compatible

- PROFINET compatible

- MECHATROLINK-III compatible

- SSCNET III/H Compatible

- Built-In Controller Type

- Pulse input type with RS-485 communication

- Pulse input type

Certificates can be downloaded from Product Details Page.

For downloading instructions, refer to Frequently Asked Questions About Downloading Data.

Tests and Monitoring With Support Software

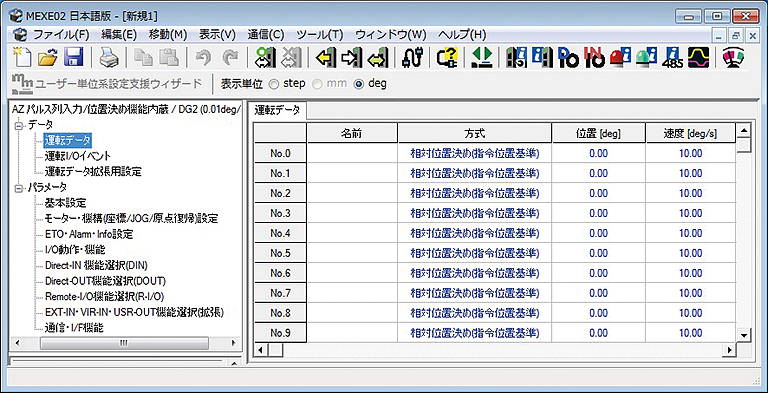

Easy Drive From PC With Support Software MEXE02

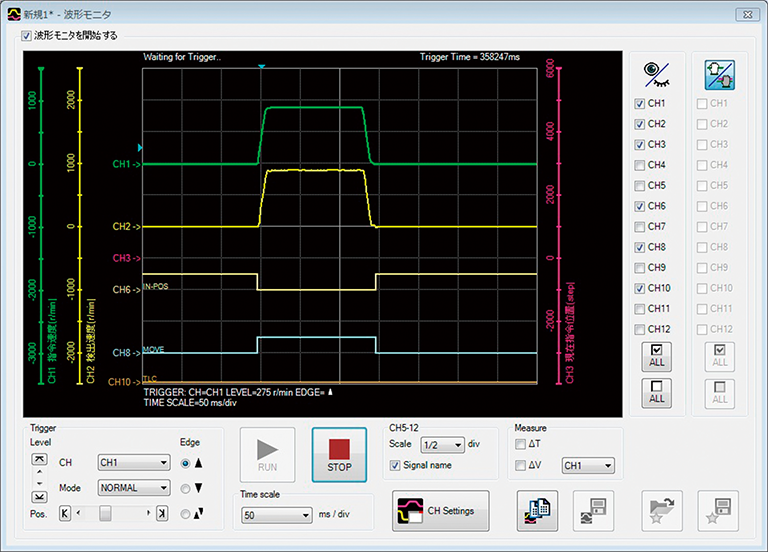

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Click Here to Download the Support Software

Comprehensive Support From Start-up to Maintenance with a Variety of Functions

-

Startup and Evaluation

Useful functions for wiring check and test operation are provided.

- Setting and Saving of Operation Data

- I/O Monitor

- Teaching, Remote Operation

-

Adjustment

The following functions are available to help you adjust motor operation after the equipment is installed.

- Waveform Monitor

-

Diagnosis and Maintenance

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitor

- Unit Information Monitor

- Status Monitor

-

Operation Data/Parameter Setting Screen -

Waveform Monitor

Narrow down Products

Download

Operating Manual

Support Software

WEB Manual

Lineup and Related Information

Combining With Other Manufacturers' Products