AC Axial Flow Fans

MRS Series and Variable Speed MRS Series

- Large Size, Large Air Volume, High Static Pressure

- The Speed of Three-Phase Fan Can be Changed via an Inverter

- Includes Low-Speed Alarm

- AC Input, Frame Size 140 to 250 mm

Features | AC axial flow fan MRS Series

Features

Features Large Air Flow

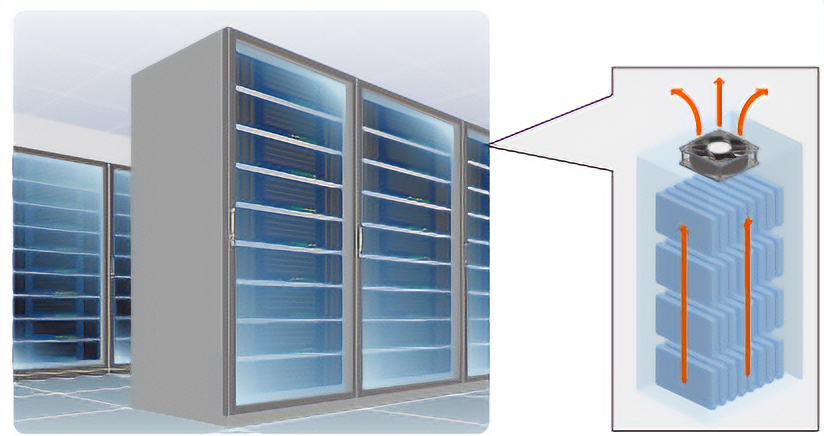

The MRS Series provides a large air flow and fast air circulation and is suitable for ventilation and cooling to cool the entire interior of the equipment.

When the ventilation resistance inside the equipment is large, it is better to use a large fan with large air flow and high static pressure to save energy and reduce wiring.

-

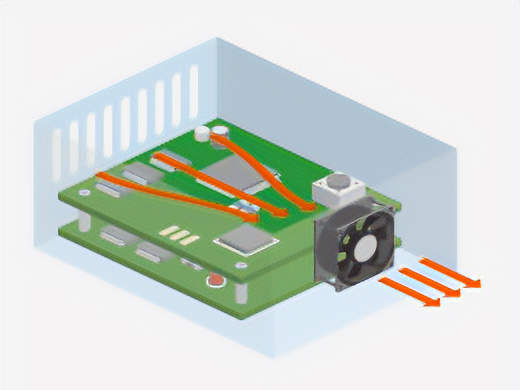

Cooling High-Density Packaging Equipment

-

Ventilation and Cooling of the Entire Interiors of the Control Cabinet and Equipment

For Even Larger Ventilation Resistance

Centrifugal blowers as well as axial flow fans are suitable for allowing air to flow through equipment with large ventilation resistance, such as high-density equipment or narrow vents. The figure below shows a characteristics diagram comparing a centrifugal blower with a maximum air flow equivalent to that of the MRS Series □140 mm.

Centrifugal blowers are fans with high static pressure compared to axial flow fans.

Air Flow - Static Pressure Characteristics

-

-

The actual air flow can be verified by the point of intersection of the characteristics line and the ventilation resistance line (operating point).

[Air Flow Rate at 50 Hz Operation]

- Axial flow fan 1.3 m3/min

- Centrifugal blower 3.3 m3/min

The centrifugal blower allows 2 m3/min more air to flow.

When the ventilation resistance is large, consider a centrifugal blower.

Low-Speed Alarm Function Equipped Predictive Maintenance

-

The alarm output function is activated when the rotation speed drops below 70 % due to unexpected circumstances such as end of service life of the cooling fans or by the ingress of foreign particles, etc.

This makes it possible to replace the fan before it comes to a complete stop.

-

Contact type fans with low-speed alarms have contact points that turn ON when rotation is normal, and can be connected in series as shown in the figure below.

An alarm signal is output even if the number of rotations of one of the multiple units drops due to some kind of malfunction. At the same time, it can also detect abnormalities such as contact failure or disconnection on the alarm circuit.

This can contribute to more reliable equipment design.

Speed Control Operation With Inverter and Variable Resistor

Noise Reduction, Power Saving and Even Longer Life, With Speed Control Operation

By adjusting the air flow according to the conditions, you can reduce noise and save power.

This also helps to reduce bearing deterioration and extend the life of the fan.

Click here for advantages of variable speed axial flow fans

Three-Phase Power Supply Input Products Can Adjust the Air Flow by Speed Control Operation Using an Inverte (Except for MRS14)

Three-Phase power supply input products can adjust the air flow by speed control operation using an inverter.

By using ceramic ball bearings, electric corrosion on the bearings due to noise can be prevented.

Air Flow - Static Pressure Characteristics (Characteristics of a single fan)

Example) When MRS18 is combined with an inverter (reference value)

- The value when a general inverter is used at factory settings.

The characteristics vary depending on the type and settings of the inverter. - Use 60 Hz or less for the inverter's setting frequency and 240 V or less for the inverter's input voltage.

- If an inverter is connected to an alarm type fan and the setting frequency is set to lower value, the rotation speed may be reduced and the alarm may be activated.

You Can See the Characteristics Data for Combinations With Inverters

Reference data for combinations with inverters from other manufacturers is made available to make it easy to connect to inverters.

[Reference Data]

- Inverter parameter setting values

- Air flow - static pressure characteristics and rotation speed/current/power consumption

Refer to the "Combining and Connecting With Products of Other Manufacturers" page

Variable Speed Type Fans Using Variable Resistors are Also Available (MRS16V-B)

Variable speed type fans using variable resistors (included) are available for 160 mm frame size.

It can be used without the need for an inverter.

Suitable for applications in which adjustment of the air flow is necessary, or applications in which a temporary decrease in noise is needed.

-

To Adjust the Speed Steplessly With a Variable Resistor (Included)

Connect the included variable resistor to the lead wire coming out of the terminal box on the fan body.

-

To Adjust the Speed Step by Step With an External Fixed Resistor

Switch over to the desired resistance with the fixed resistors (1/4 W min.) using a switch, relay, etc.

Application Examples

Application Examples of the High Efficiency, High-Characteristics MRS Series

The MRS Series, with its large air flow and high static pressure, is suitable for cooling equipment that is crammed with devices inside with large air loss while air is flowing.

- Example)

- When cooling equipment with a board mounted with a heat generation of 120 W

Six MU1238 type units and one MRS16 type unit will provide approximately the same cooling effect.

Energy Savings

With the MRS16 type fans, power consumption can be reduced by 60 %, reducing the running costs which include the electricity fees.

| MRS16 | MU1238 | |

|---|---|---|

| Fan Size | □160 mm - 62 mm thick | □119 mm - 38 mm thick |

| Number of Units | 1 unit | 6 units |

| Power Consumption | 37.5 W | 92.5 W |

| Annual Electricity Bill | 6,750 JPY | 16,206 JPY |

| Noise | 49 dB | 51 dB |

- *Electricity costs are converted at 20 JPY/kWh. When the fans are operating 24 hours a day, 365 days a year

Power consumption is reduced by 60 %

Simple Wiring

The MRS16 type fans can be used to reduce the amount of time and effort required to mount and wire the equipment.

| MRS16 | MU1238 | |

|---|---|---|

| Fan Size | □160 mm - 62 mm thick | □119 mm - 38 mm thick |

| Number of Units | 1 unit | 6 units |

| Number of Wires | 3 | 12 |

| Mounting Hole Processing (Number of screws) |

4 | 24 |

| Temperature Rise Inside the Equipment |

25 °C | 25 °C |

- *For Single-Phase 100 VAC, 50 Hz

Reduces the time and effort required for machining mounting holes and wiring

Detects Failure and Low-Air Flow

The MRS16 type fans are available with a low-speed alarm so that they can be replaced before it causes damage to the equipment in the unlikely event of deterioration in air flow.

- *The above is an example. Use Oriental Motor’s motor sizing service to find the best cooling fan for the mounting density and operating conditions.

Can be Used with the Accessory Sets

Easy Setup With the Finger Guard Set

Finger guards, mounting screws, and filters are included in the set of accessories necessary to use the fan.

Because these products are sets, there is no need to order individual components, and they can be assembled onto the fan immediately upon arrival.

- *Finger guard set is sold separately.

Set Contents

-

Finger Guard Set (1 Guard)*1

- Steel finger guard set

- Stainless steel finger guard set

-

Finger Guard Set (2 Guards)

- Steel Finger Guard Set

- Stainless Steel Finger Guard Set

-

Finger Guard and Filter Set (1 Each)

- Steel finger guard and filter set

Mounting Example

-

-

Finger guards are used outside the control cabinet

- Outside →

- For preventing injury

-

-

-

Finger guards are used on both the inside and outisde of the control cabinet

- Inside →

- For protection of the workers

- Outside →

- For preventing injury

-

-

-

Finger guards are used on the inside of the control cabinet, and filters are used on the outside

- Inside →

- For Protection of the Workers

- Outside →

- For protection against dust

-

- *1

- The variable speed type fans include 1 finger guard. Use in combination with the 1-guard set.

Product Line

MRS Series

| Size | Type and Alarm Product Line | ||

|---|---|---|---|

| □140 mm - 47 mm thick | Non-alarm type | ||

| Low-speed alarm | Electronic alarm type | ||

| □160 mm - 62 mm thick | Non-alarm type | ||

| Low-speed alarm | Contact alarm type | During Normal Rotation: Contact ON Normal Rotation: Contact OFF |

|

| Electronic alarm type | |||

| □180 mm - 90 mm thick* | Non-alarm type | ||

| Low-speed alarm | Contact alarm type | During Normal Rotation: Contact ON | |

| Electronic alarm type | |||

| □200 mm - 90 mm thick | Non-alarm type | ||

| Low-speed alarm | Contact alarm type | During Normal Rotation: Contact ON | |

| Electronic alarm type | |||

| □250 mm - 120 mm thick | Non-alarm type | ||

| Low-speed alarm | Contact alarm type | During Normal Rotation: Contact ON | |

| Electronic alarm type | |||

- The product with extension cable is scheduled to be discontinued.

Long life type AC axial flow fans are also available. Refer to the MRE Series.

Narrow down Products