Hollow Rotary Actuators

DH Series

- Integrated Hollow Table and Stepper Motor

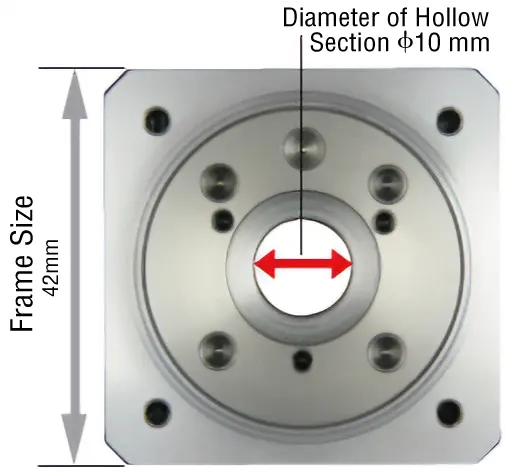

- Frame Size 28/42 mm

- Diameter of Hollow Section φ5.2/10 mm

Features | Hollow Rotary Actuator DH Series

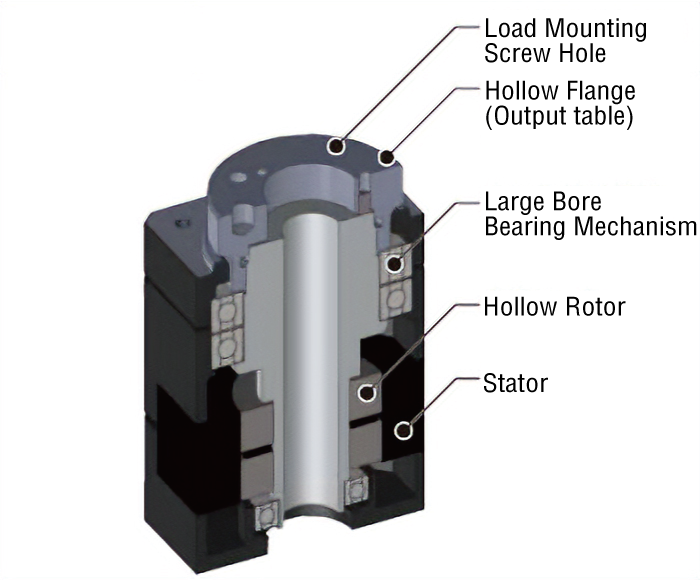

Hollowness Simplifies Piping and Wiring at the End of the Equipment

This actuator is a 5-phase stepper motor with a hollow flange. Air piping, wiring, and rays are passed through the hollow section, contributing to a simplified design, smaller size, and lighter weight at the end of the equipment.

-

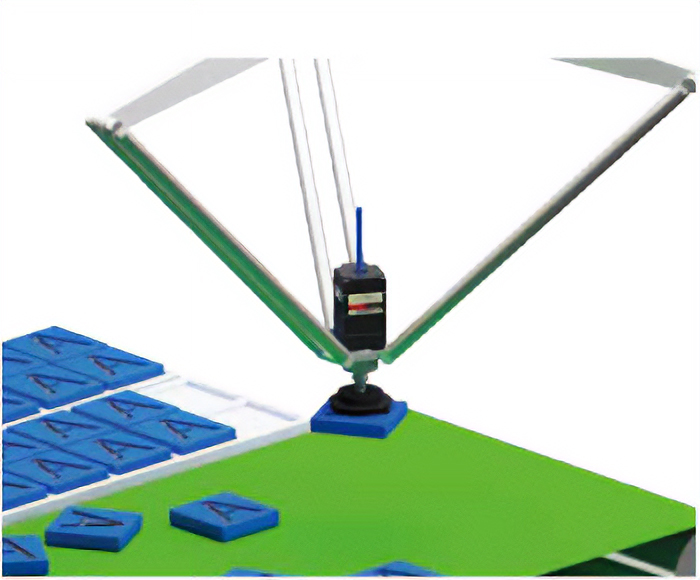

Parallel Link Robot

θ Axis of Adsorber -

Product Name Frame Size Diameter of Hollow Section Mass DHM28PAK2 28 mm φ5.2 mm 0.17 kg DHM42PAK 42 mm φ10 mm 0.47 kg

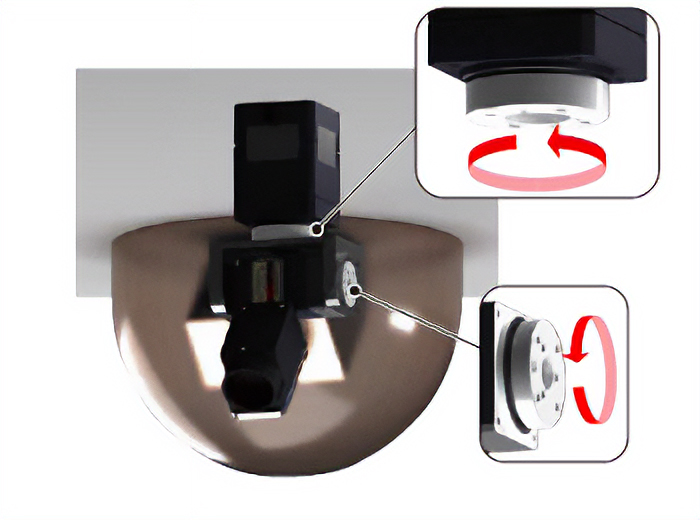

Flange Mount Contributes to the Reduction of Parts Around Moving Parts

The load can be directly mounted to the hollow flange. This contributes to reducing the number of parts around moving parts.

-

Rotational Axis of Security Cameras -

Example: Using DHM42PAK

Some of the conventional parts have been eliminated, so the time required for equipment design and product selection is shortened.

Furthermore, the number of man-hours required for assembly and the adjustment of installation accuracy can be reduced, contributing to higher productivity.

Advantages of Using the Equipment

- Reduction of Design Time

- Lower Parts Cost

- Reduction of Assembly Man-Hours

- Reduction of Accuracy Adjustment Time

- Reduction of Maintenance Time

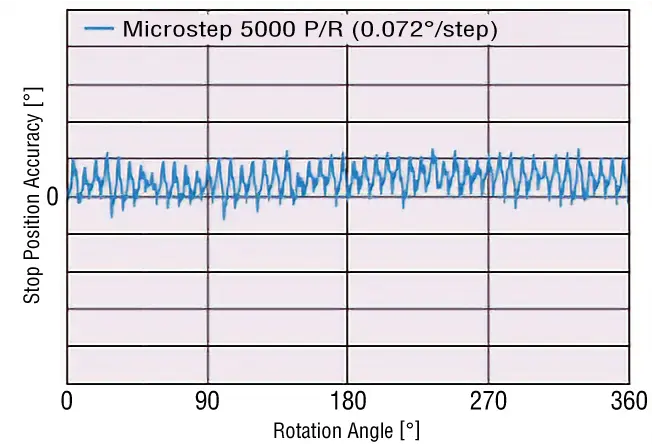

Highly Accurate Positioning

Equipped with a 5-phase stepper motor, it can perform highly accurate positioning and fine operations stably and repeatedly. Microstep drive and smooth drive function in combination with the CVD driver enable smooth operation with low speed vibration. The hollow flange does not use transmission mechanisms such as couplings or belts, so accuracy is not affected by component rigidity or combination errors.

-

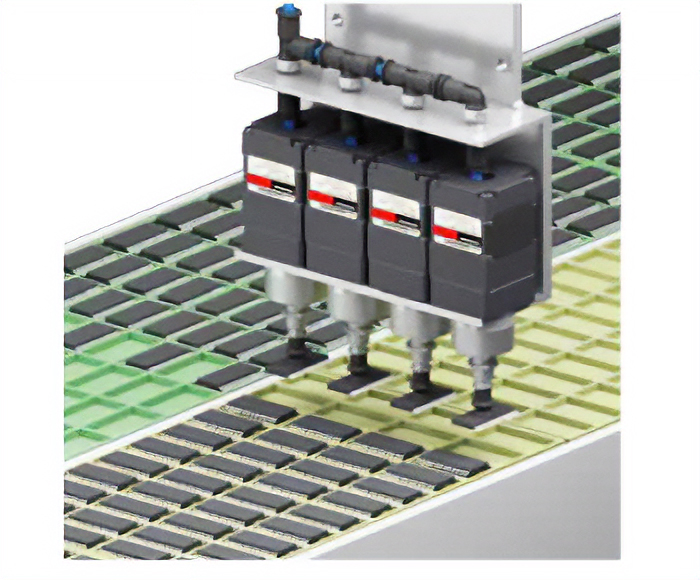

Parts Mounter

θ-Axis of Parallel AdsorberAdvantages of Using the Equipment

- Highly Accurate Parts Alignment

- Lighter Adsorber Unit

- Smaller Suction Unit Thanks to Parallel Arrangement

-

Product Name Stop Position Accuracy Repetitive Positioning Accuracy DHM28PAK2 ±0.33˚ ±0.15˚ DHM42PAK ±0.11˚ ±0.05˚

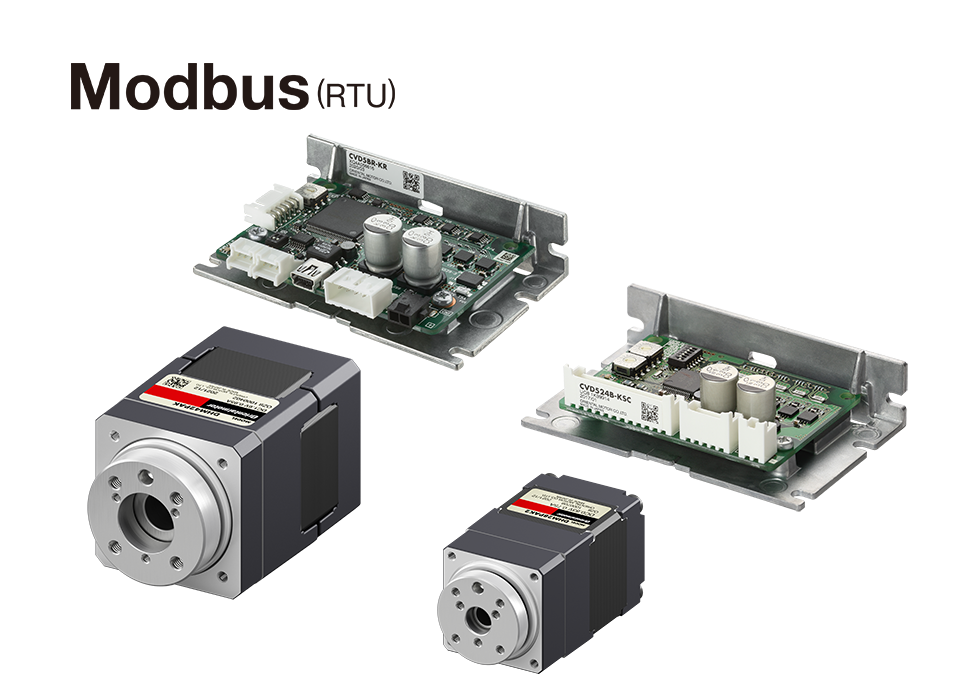

Driver Features

Product Line

The actuator, driver, and connection cable can be purchased individually.

Actuator

| Product Name | Frame Size | Diameter of Hollow Section | Stop Position Accuracy | Repetitive Positioning Accuracy | Maximum Holding Torque |

|---|---|---|---|---|---|

| DHM28PAK2 | 28 mm | φ5.2 mm | ±0.33˚ | ±0.15˚ | 0.029 N·m |

| DHM42PAK | 42 mm | φ10 mm | ±0.11˚ | ±0.05˚ | 0.175 N·m |

Driver

| Driver Type | Power Supply Input | |

|---|---|---|

|

|

Pulse input | 24 VDC |

| RS-485 Communication |

Connection Cables/Flexible Connection Cables

Frame Size 28 mm

- Use flexible connection cables for applications where cables are bent.

- A "driver side extension cable" is also available to add to the connection cable.

| Length [m] |

|

|---|---|

|

0.5~10 |

Frame Size 42 mm

The connector is attached to the driver side.

- Use flexible connection cables for applications where cables are bent.

- An "extension connection cable without terminal treatment" for use between the motor and driver is also available.

| Length [m] |

|

|---|---|

|

0.5~1 |

Note

Keep a maximum distance of 10 m for the wiring between the motor and the driver.

Related Products

Stepper Motor PKP Series/

CVD Series Pulse Input Driver

You want to operate a stepper motor easily by pulse input. This is a motor and pulse input driver that meets such needs. In pursuit of high efficiency, high torque, and low vibration, even better performance has been achieved.

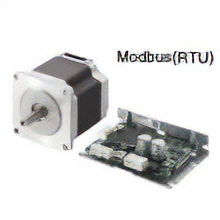

Stepper Motor PKP Series/

CVD Series RS-485 Communication Type Driver

You want to run a stepper motor under Modbus (RTU) control. You want to set data easily on a touch screen. This product combines a motor with a driver that supports RS-485 communication compatible to meet such needs. Up to 31 axes of drivers can be controlled by connecting them to a single host control device.

Narrow down Products

Download

Catalog

Operating Manual

Support Software

Lineup and Related Information

Combining With Other Manufacturers' Products