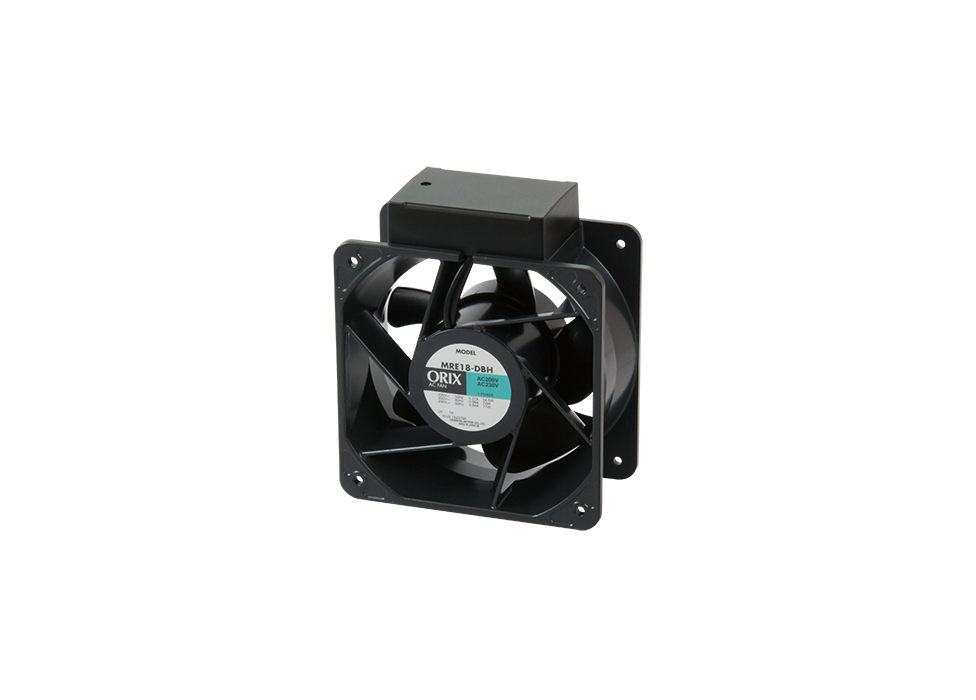

AC Long-Life Axial Flow Fans

MRE Series

- Long Life with Expected Life of 100,000 Hours

- The Speed of Three-Phase Fan Can be Changed via an Inverter

- Includes Low-Speed Alarm

- AC Input, Frame Size 160 to 250 mm

Features | AC long-life axial flow fan MRE Series

Features

Long Life With Expected Life of 100,000 Hours (Approx. 11 years)

This long life fan can withstand continuous duty for about 11 years.

The temperature rise of the bearing has been reduced, and the deterioration of grease, which affects the lifetime of the fan, has been suppressed.

Measures have been taken for longer service life of circuit/coupling and reduction of failure rate.

It is designed not only to prevent initial failure, but also to prevent accidental and abrasion failures.

[Expected Life]

The expected life indicates that 90 % min. of the fans will satisfy the following criteria when the acceleration test is performed at an operating ambient temperature of 60 °C (for MRE10, MRE12, 50 °C).

Criteria (For MRE Series)

- Rotation speed (at rated voltage): 70 % min. of rated value

- Input current (at rated voltage) : 130 % max. of rated value

Longest* Service Life in the Industry

The □250 mm axial flow fan is highly efficient with a winding design that meets the power supply specifications of each country, and suppresses the temperature rise of the cooling fans.

It has achieved the longest* service life in the industry.

- *As of March 2021. Industrial Axial Flow Fan/AC Input Type/Same Size/Research by Oriental Motor

Lower Maintenance Costs and Overall Costs

As a result, fewer fan replacements are needed, reducing costs.

- *Estimated life is 35,000 hours at an ambient temperature of 60 °C. The estimated life is an estimated value calculated using the formula for the life of the bearing grease. The estimated life varies depending on the product name.

Suitable for Hard-to-Maintain Environment

The long life and low failure rate make it ideal for environments and equipment that are difficult to maintain.

[Example environment where maintenance cannot be easily performed]

- Equipment is in continuous operation and cannot be stopped

- Locations that are difficult to access such as on roads or in underground areas

- Equipment that needs to be delivered or installed in remote areas

Low-Speed Alarm Function Equipped Predictive Maintenance

An alarm signal is output when the rotation speed of the fan deteriorates due to ingress of foreign particles, etc. This helps with predictive maintenance of equipment issues, as fans can be ordered and replaced before equipment is damaged by heat. It also allows replacement of only those fans with deteriorating cooling capacity when there are multiple fans installed. It can limit the impact on the equipment to minimum.

Connector Connections Can Reduce Wiring Work

Since the fan and cable are connected by a connector, wiring work can be reduced.

For products with single-phase power supply, the capacitor is built into the fan body. Wiring for the capacitors used to be a hassle, but it is now hassle-free with connectors.

Speed Control Operation Using an Inverter

Speed Control Operation for Low Noise and Power Saving

By adjusting the air flow according to the conditions, you can reduce noise and save power.

Click here for advantages of variable speed axial flow fan

Three-Phase Power Supply Input Products Can Adjust the Air Flow by Speed Control Operation Using an Inverter

Three-Phase power supply input products can adjust the air flow by speed control operation using an inverter.

By using ceramic ball bearings, electric corrosion on the bearings due to noise can be prevented.

Air Flow - Static Pressure Characteristics (Characteristics of a single fan)

Example) When MRE25 is combined with an inverter (reference value)

- The value when a general inverter is used at factory settings.

The characteristics vary depending on the type and settings of the inverter. - Use 60 Hz or less for the inverter's setting frequency and 240 V or less for the inverter's input voltage.

- If an inverter is connected to an alarm type fan and the setting frequency is set to lower value, the rotation speed may be reduced and the alarm may be activated.

You Can See the Characteristics Data for Combinations With Inverters

Reference data for combinations with inverters from other manufacturers is made available to make it easy to connect to inverters.

[Reference Data]

- Inverter parameter set values

- Air flow - static pressure characteristics and rotation speed/current/power consumption

Refer to the "Combining and Connecting With Products of Other Manufacturers" page

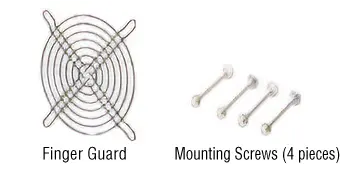

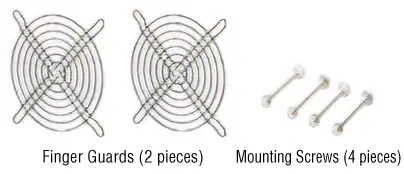

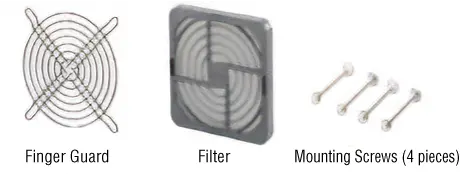

Can be Used With the Accessory Sets

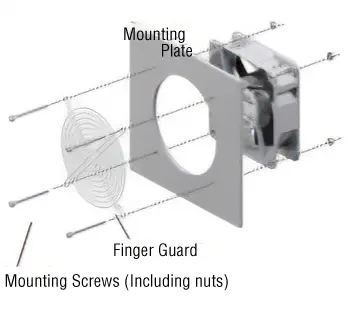

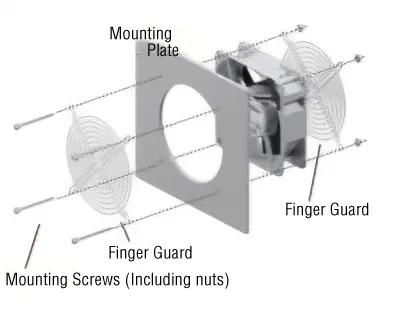

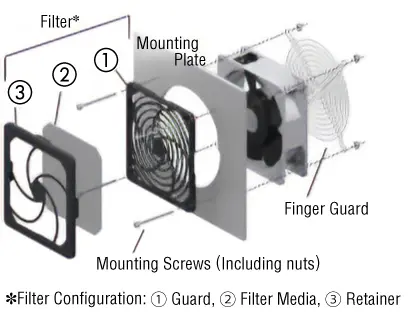

Easy Setup With the Finger Guard Set

Finger guards, mounting screws, and filters are included in the set of accessories necessary to use the fan.

Because these products are sets, there is no need to order individual components, and they can be assembled onto the fan immediately upon arrival.

- *Finger guard set is sold separately.

Set Contents

-

Finger Guard Set (1 Guard)

- Steel Finger Guard Set

- Stainless Steel Finger Guard Set

-

Finger Guard Set (2 Guards)

- Steel Finger Guard Set

- Stainless Steel Finger Guard Set

-

Finger Guard and Filter Set (1 Each)

- Steel Finger Guard and Filter Set

Mounting Example

-

-

Finger guards are used outside the control cabinet

- Outside →

- For Preventing Injury

-

-

-

Finger guards are used on both the inside and outisde of the control cabinet

- Inside →

- For Protection of the Workers

- Outside →

- For Preventing Injury

-

-

-

Finger guards are used on the inside of the control cabinet, and filters are used on the outside

- Inside →

- For Protection of the Workers

- Outside →

- For Protection Against Dust

-

product Line

| Size | Voltage [V] |

Maximum Air Flow [m3/min] |

Maximum Static Pressure [Pa] |

|---|---|---|---|

| □104 mm - 28 mm thick* | Single-Phase 100 | 1.1~1.3 | 59~78 |

| Single-Phase 200 | |||

| □119 mm - 28 mm thick* | Single-Phase 100 | 1.8~2.1 | 70~91 |

| Single-Phase 200 | |||

| □160 mm - 62 mm thick | Single-Phase 100/110/115 | 6.2~7.3 | 127~157 |

| Single-Phase 200/230 | |||

| Single-Phase 220/230/240 | 6.2~7.6 | 127~170 | |

| Three-Phase 200/220/230 | 127~157 | ||

| □180 mm - 90 mm thick | Single-Phase 100/110/115 | 11~12.8 | 196~245 |

| Single-Phase 200/230 | |||

| Single-Phase 220/230/240 | 196~270 | ||

| Three-Phase 200/220/230 | 196~245 | ||

| □200 mm - 90 mm thick | Three-Phase 200/220/230 | 13.2~16 | 221~300 |

| □250 mm - 120 mm thick | Single-Phase 100/110/115 | 20~23 | 300~330 |

| Single-Phase 200/220/230 | 300~375 | ||

| Three-Phase 200/220/230 | 305~370 |

- *This product is scheduled to be discontinued. Please contact Oriental Motor for details.

Related Products

DC long life axial flow fans are also available.

Narrow down Products

Download

Catalog

F-78

AC Input Long-Life Axial Flow Fan MRE Series □250 mm - 120 mm Thickness