Electric Linear Slides

EAS Series

Electric linear slides equipped with a high efficiency, energy saving αSTEP AZ Series motor. Compact and high-strength for a wide range of applications.

Features | Electric Linear Slide EAS Series

Features of Linear Slide Section

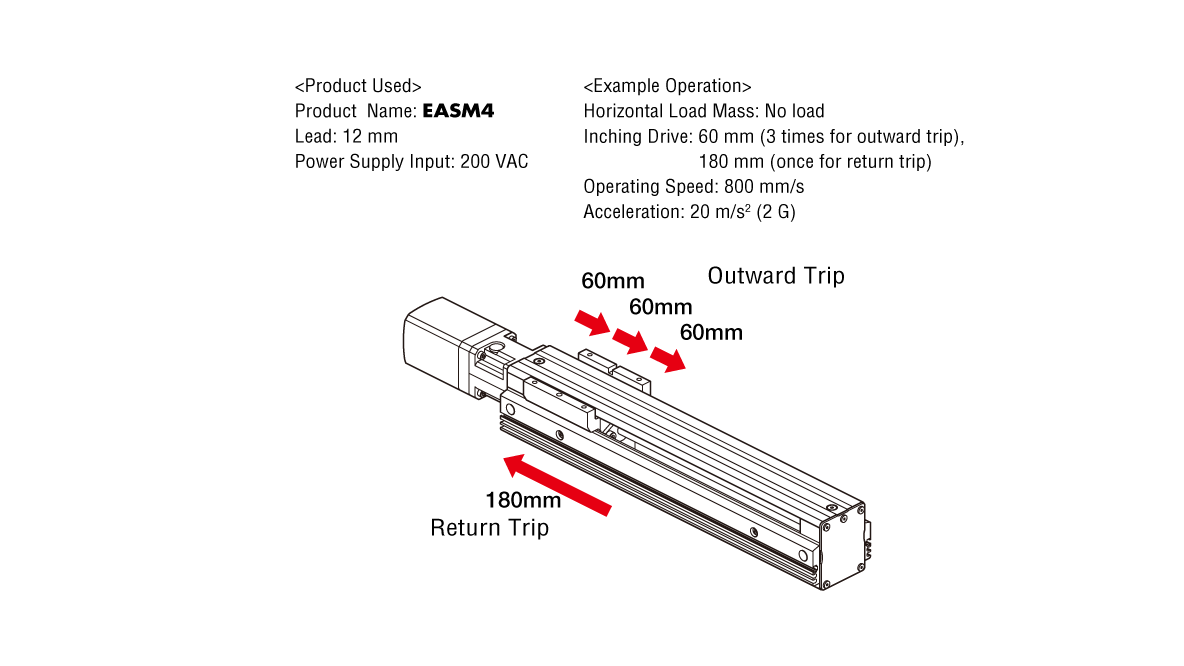

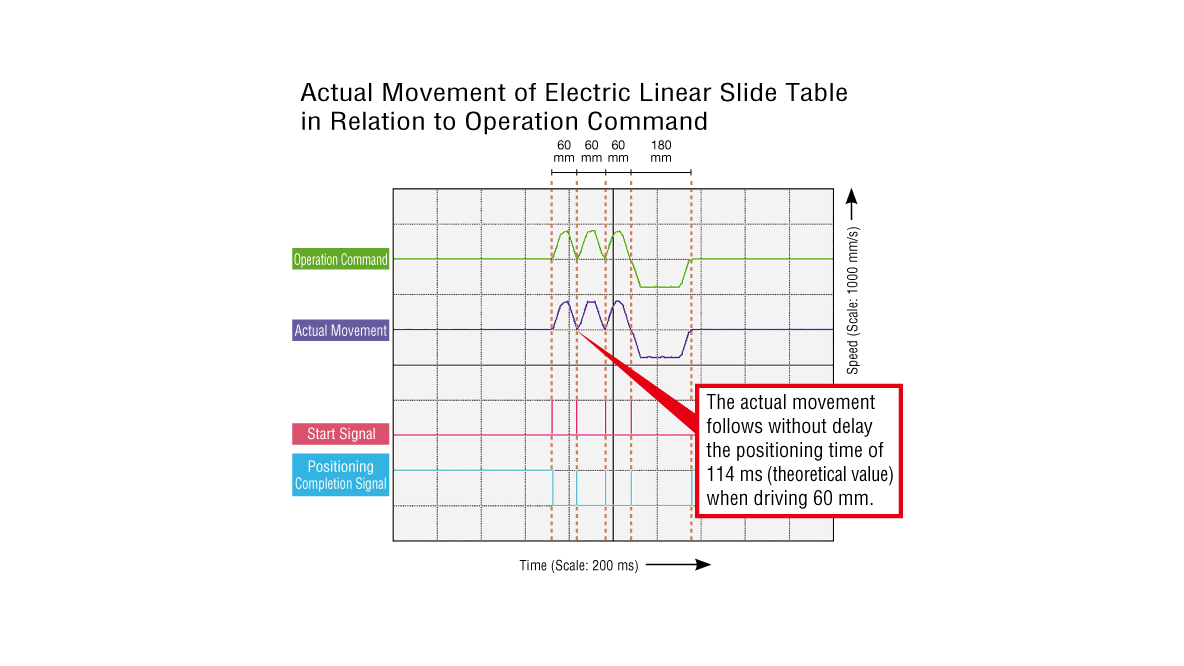

Agile Responsiveness

By utilizing the high responsiveness of the closed loop stepper motor, quick short distance positioning is possible.

It also helps shorten the takt time of the equipment.

Closed loop stepper motors operate synchronously with pulse commands and generate high torque with a compact body, and offer excellent acceleration performance and responsiveness.

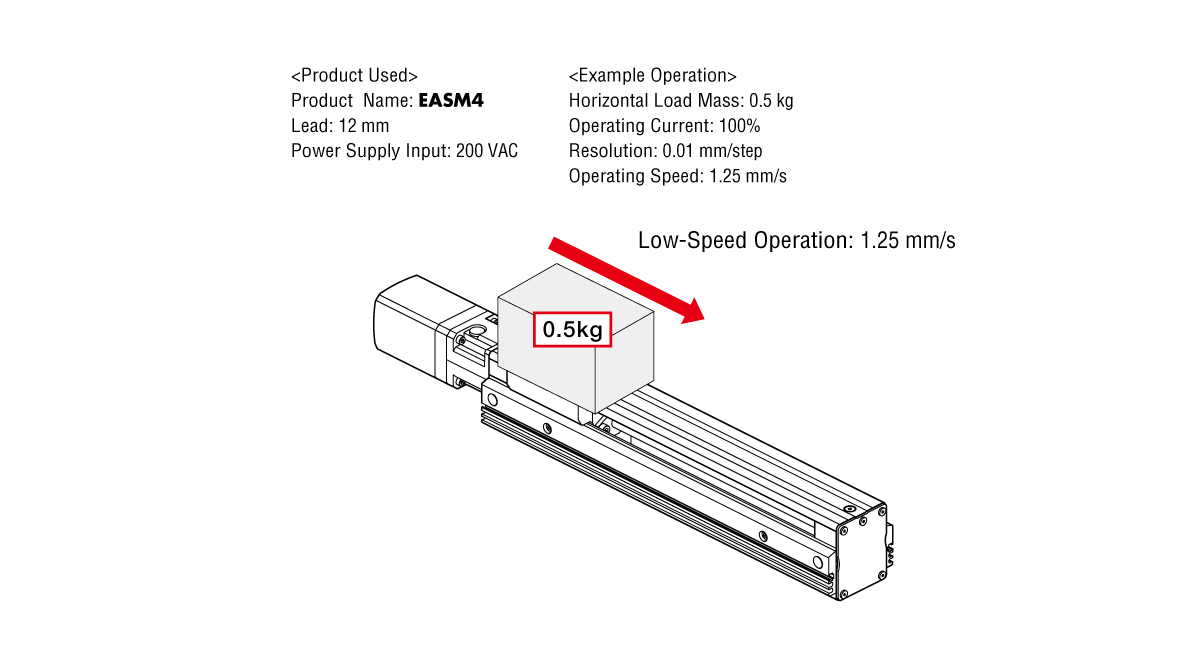

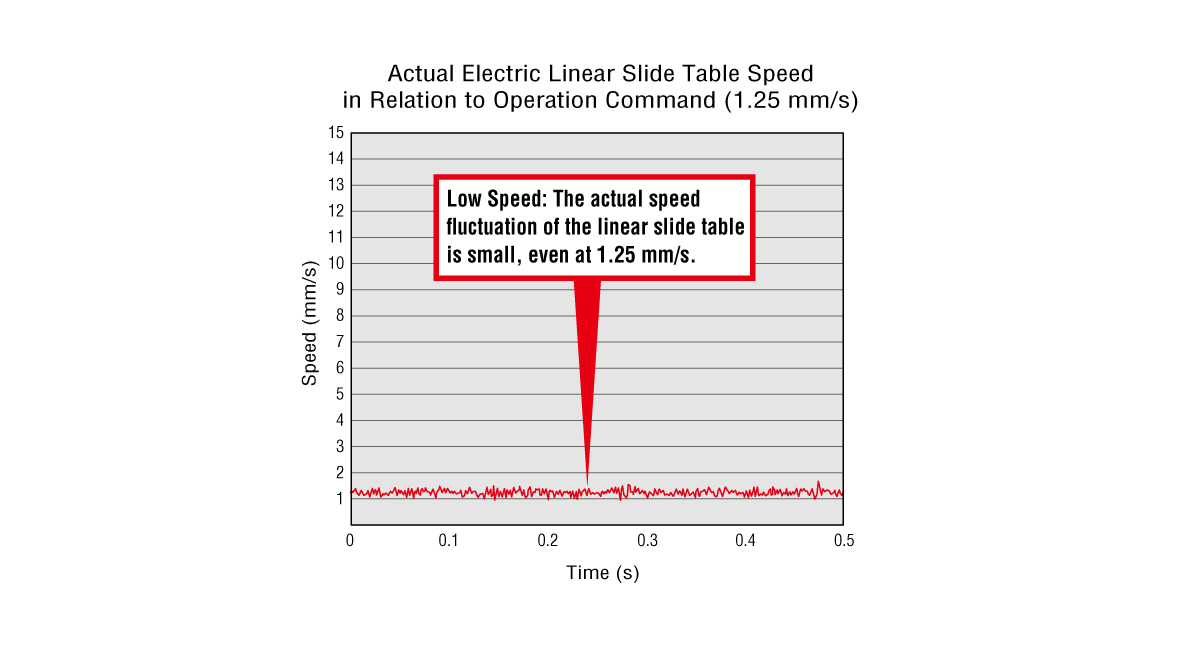

Stability at Low Speeds

Thanks to the microstep drive system and smooth drive function* of the closed loop stepper motor, resolution can be improved without mechanical elements such as a speed reduction mechanism. As a result, speed fluctuation is minimal even at low speeds, leading to improved stability.

- *About the Smooth Drive Function

The smooth drive function automatically microsteps based on the same travel amount and traveling speed used in the full step mode, without changing the pulse input settings.

High Accuracy

This is an electric linear slide with ball screw and the LM guide* manufactured by THK. This slide is suitable for applications where traveling parallelism is required because the highly accurate LM guide is directly installed to customer's enclosure base (traveling parallelism is 0.03 mm).

- *"LM Guide" is a Registered Trademark of THK Co., Ltd.

Linear Slide Variation

Product Line

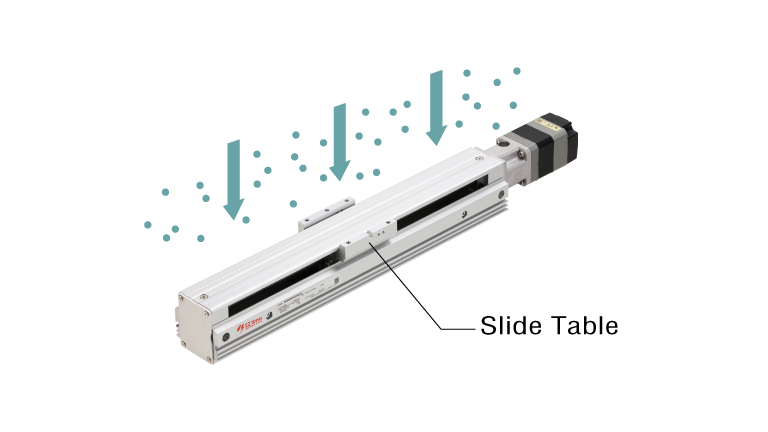

X-Table

-

-

This type can reduce the intrusion of falling foreign particles when it is used in X-tables.

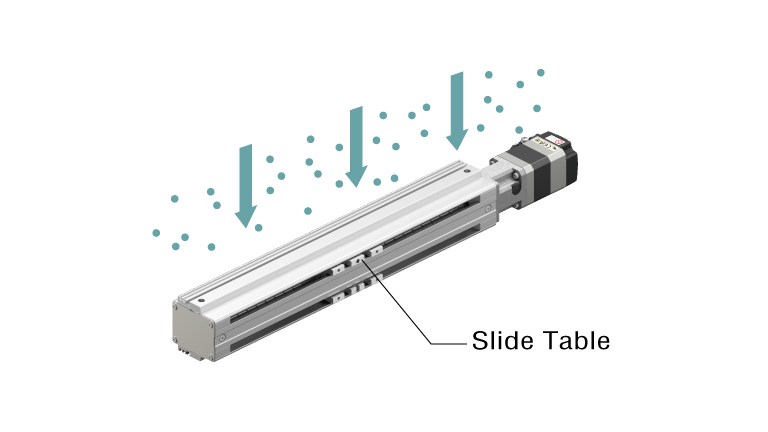

Y-Table

-

-

This type can reduce the intrusion of falling foreign particles when it is used in Y-tables.

Avoidance of Interference With Peripheral Equipment

The mounting direction of the motor can be changed in 4 directions, allowing the cable outlet direction to be freely changed to suit the installation location.

With Sensor Rail

Sensors of the sensor set (sold separately) can be fixed to the sensor rails on the left and right sides. The wiring from the sensor can also be stored in the groove of the sensor rail. This eliminates the need to fix the wires, thus preventing wire breakage due to snagging.

Advantages of AZ Series Equipped

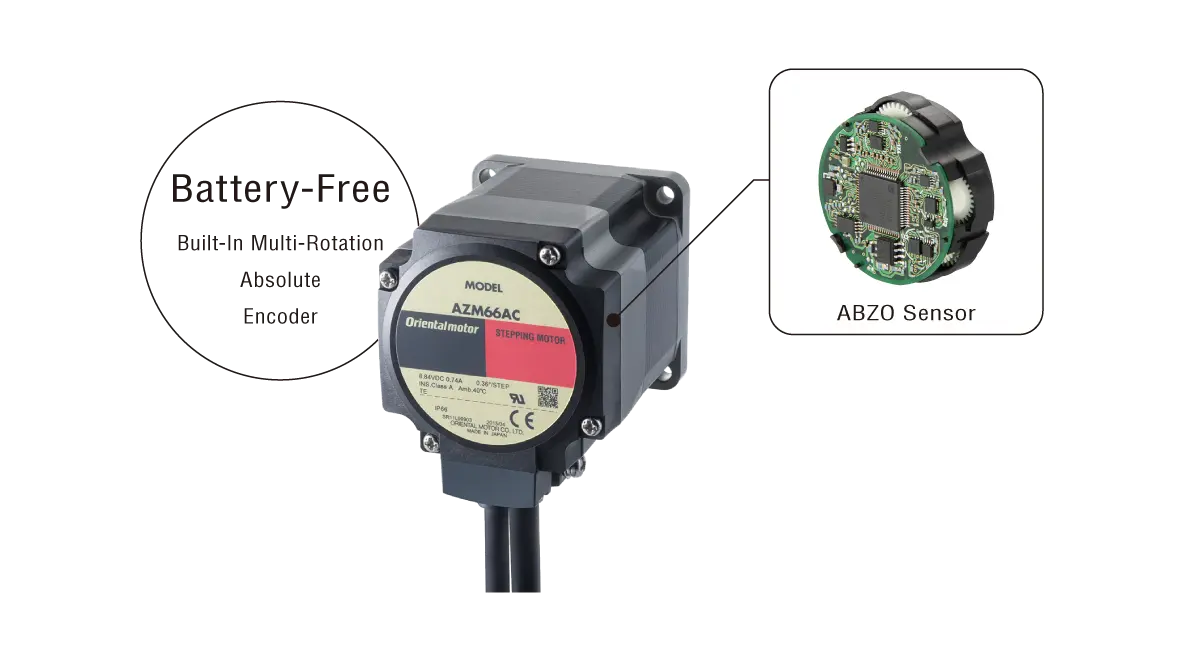

Battery-Free Absolute Encoder Equipped

It is equipped with a small battery-free mechanical absolute encoder (ABZO sensor). This can help improve productivity and reduce costs.

- Mechanical-Type Sensor

Retains positioning information even when power is not supplied - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 (1,800) revolutions of the motor shaft from the home position

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved High-Speed Return-to-Home + Return-to-Home Accuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunction

Battery-Free

Mechanical sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.

Advantages

- No need to replace batteries

- Unlimited Driver Installation Possibilities

- Safe for Overseas Shipping

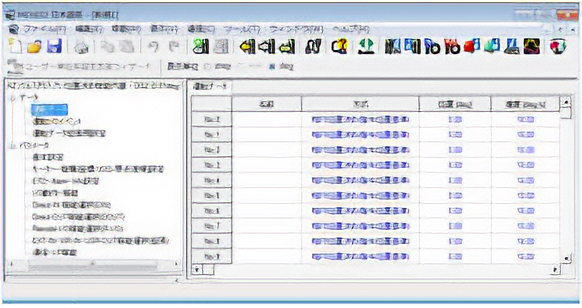

Simplifying the Main Program via Sequence Function

The AZ Series come equipped with a wide variety of sequence functions such as timer settings for linked operation and during operations, conditional branching, and loop operation. (excluding some models)

It can be set up using the support software MEXE02, which simplifies the sequence program of the host system.

- Positioning Operation Data Setting Value (max. 256)

- General-Purpose I/O Signal Counts (Input 10, Output 6)

- Communication I/O Signal Counts (Input 16, Output 16)

-

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved high-speed return-to-home + return-to-home accuracy

- Reduced cost

- Simple wiring

- Not affected by external sensor malfunctions

-

Battery-Free

Mechanical-type sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.Advantages

- No need to replace batteries

- Unlimited driver installation possibilities

- Safe for overseas shipping

Data Collection of Motor Operation Status and Functions Useful for Preventive and Predictive Maintenance

This software is equipped with various monitoring functions for checking the operating status of the motor.

By using different types of equipment for different situations, it is possible to shorten the start-up and adjustment time of the equipment, as well as to utilize it for maintenance and servicing.

Monitoring Function to Visualize the Motor Operating Status and Help Collect Data

The ABZO sensor bulit in the AZ Series allows you to monitor the motor's operating status numerically.

[Monitoring With MEXE02 Support Software]

In addition, the built-in controller type can realize data collection at a host master via industrial network.

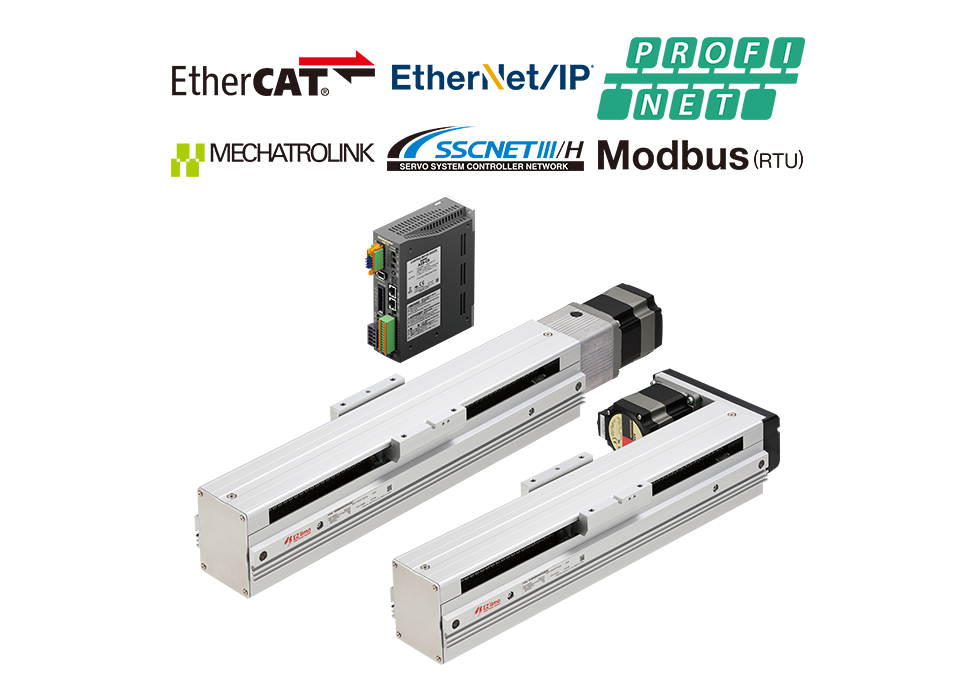

Types of network converters and the industrial networks they support

Information Functions Useful for Preventive and Predictive Maintenance

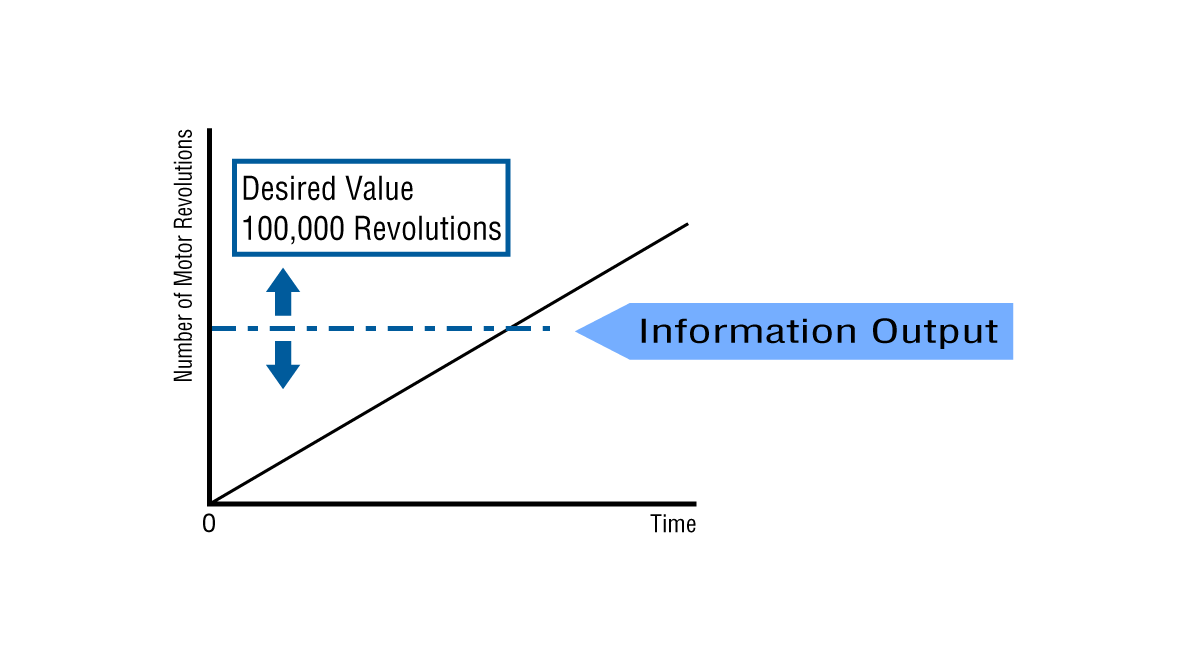

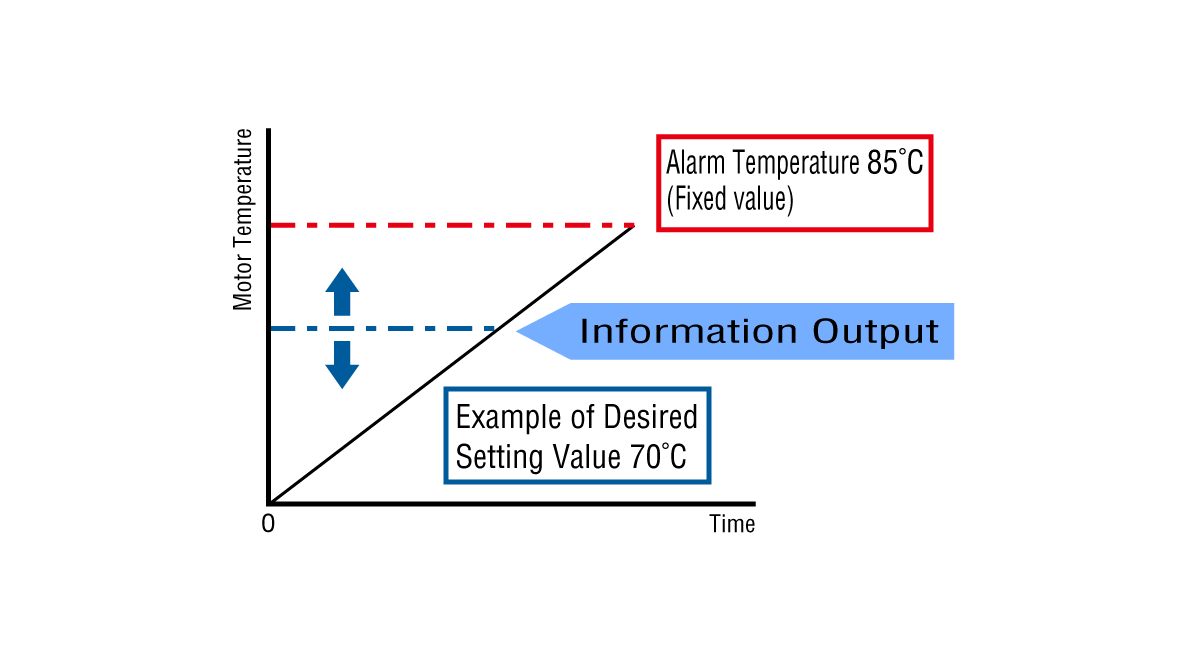

By setting arbitrary numerical values for the monitored information items, external signals can be output when the values are reached.

Importing this information into the host controller helps in early detection of problems and adjustment of product maintenance timing.

Examples of Information Functions

-

TRIP Information

You can set the number of rotations you want to output in advance, and output when that number is reached. (Motor operation will continue)

-

Temperature Information

You can set the desired output temperature in advance, and the driver will output when it reaches that temperature. (Motor operation will continue)

Standardized Wiring, Control, and Maintenance Parts

Various actuator products equipped with the αSTEP AZ Series are available.

They each have the same motor and driver, which allows for standardized wiring, control, and maintenance parts.

Wiring Standardization

The wiring for motor cables, I/O signals, and power supply is the same.

Control Standardization

These products can be operated via the same method, since the control method is the same. For the network control, the remote I/O and the command code are also the same. It saves you the trouble of creating a program.

Unification of Maintenance Parts

Maintenance parts can be minimized, since the motor, driver, and cable are common to all. Management costs (parts cost, management space) can be reduced.

AZ Series-Equipped Product Line

Electric Actuators (AZ Series equipped)

| Electric Linear Slide | Electric cylinder | Compact Electric cylinder | Rack-and-Pinion System | Electric Gripper | Hollow Rotary Actuator |

|---|---|---|---|---|---|

| EAS Series EZS Series EZSH Series |

EAC Series | DR Series DRS2 Series |

L Series | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Refer to each series page for the detailed product line.

Driver Features and Product Line

Drivers That Can be Selected to Match the Host Controller

The lineup is available for a variety of controls, systems, and interfaces.

| Driver Type | Compatible Interfaces | Single Axis Driver | ||

|---|---|---|---|---|

| AC Input | DC Input | |||

|

|

|||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ | ○ |

| EtherNet/IP™ | ○ | ○ | ||

| PROFINET | ○ | ○ | ||

| MECHATROLINK-Ⅲ | ○ | − | ||

| SSCNETⅢ/H | ○ | − | ||

| Built-in Controller | Operation data is built into the driver. Controllable via Modbus (RTU) and I/O. Can be controlled via CC-Link by using a network converter. |

Modbus (RTU) I/O CC-Link* |

○ | ○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse input Modbus (RTU) |

○ | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ | ○ |

- DC input mini drivers and multi-axis driver lineups are also available.

- *Available when using a network converter (sold separately).

- *EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *EtherNet/IP™ is a trademark of ODVA.

- *PROFINET is a trademark or registered trademark of PROFIBUS Nutzerorganisation e.V. (PNO).

- *MECHATROLINK is a registered trademark of the MECHATROLINK Members Association.

- *SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

- *CC-Link is a registered trademark of the CC-Link Partner Association.

Support Software, Monitor Functions

Easy Drive From PC with Support Software MEXE02

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Click Here to Download the Support Software

Comprehensive Support From Start-up to Maintenance with a Variety of Functions

-

Startup and Evaluation

Useful functions for wiring check and test operation are provided.

- Setting and Saving of Operation Data

- I/O Monitoring

- Teaching, Remote Operation

-

Adjustment

The following functions are available to help you adjust motor operation after the equipment is installed.

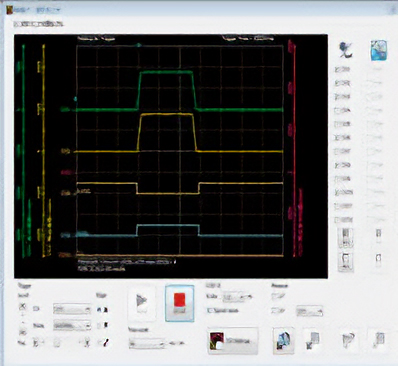

- Waveform Monitoring

-

Diagnosis and Maintenance

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitoring

- Unit Information Monitor

- Status Monitor

-

Operation Data/Parameter Setting Screen -

Waveform Monitoring

Related Products

AZ Series Multi-Axis Driver DC Input

You can connect the Oriental Motor AZ Series DC input motors and electric actuators equipped with such motors.

-

2-Axis Type -

3-Axis Type -

4-Axis Type -

NEW

Slim Type

(4 axes)

- The slim type is only compatible with EtherCAT. For more details, please contact your nearest branch, sales office, or Customer Support Center.

- *EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

- *SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

AZ Series mini Driver DC Input

This is a mini driver designed to be more compact and lightweight than a box-style driver. Also compatible with battery power supply, so it can be used for an even wider range of applications than before.

Narrow down Products

Download

Catalog

Operating Manual

Support Software

Lineup and Related Information

Technical Data (Table deflection/rigidity)

Combining With Other Manufacturers' Products