Case Study of Battering Machines and Battering Uniformity by Adjusting Air Flow Rate of the Centrifugal Blower

Issue

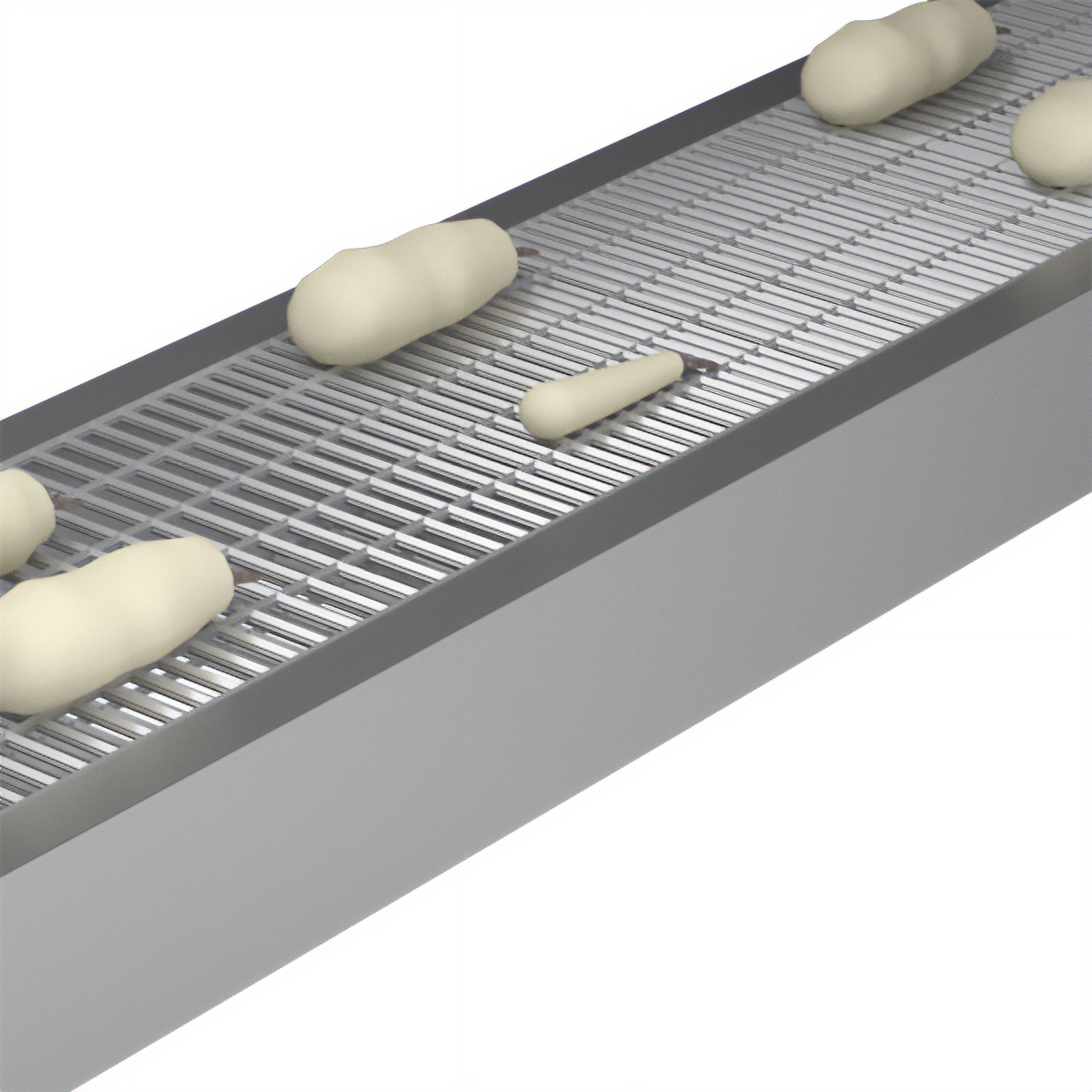

Making the batter uniform before frying with a fryer

Conventional Equipment

The process of adding batter liquid (flour mixed with water) to fried foods

- Application

- Food processing machines

Conventional Problems

- The quality varies due to unevenness in the way the batter liquid is applied

Solution

Centrifugal Blower MB Series S Type

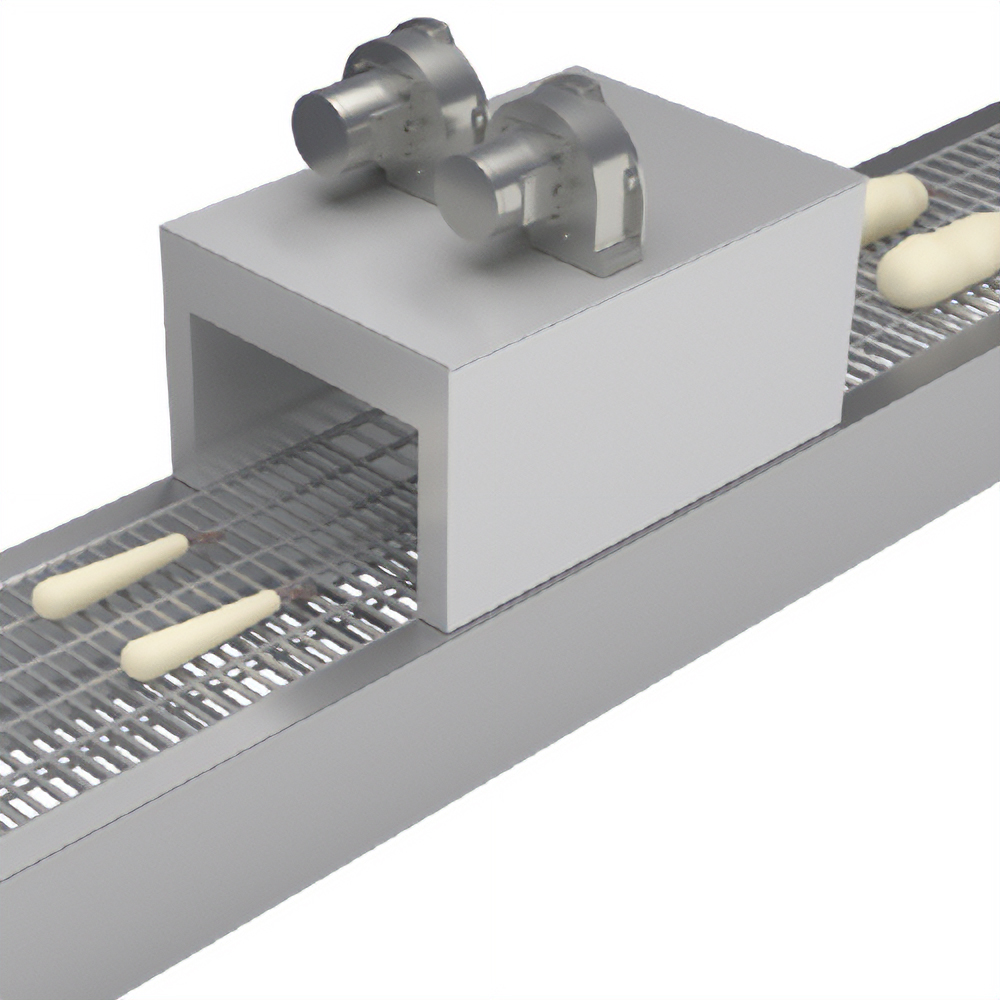

Eliminates unwanted batter liquid and reduces quality variation

The high static pressure of the MB Series S type allows excess batter liquid to be blown off for even battering.

Specific Application Examples

Watch the video on fan product lines and applications

High Static Pressure Makes It Ideal for Blowing Applications

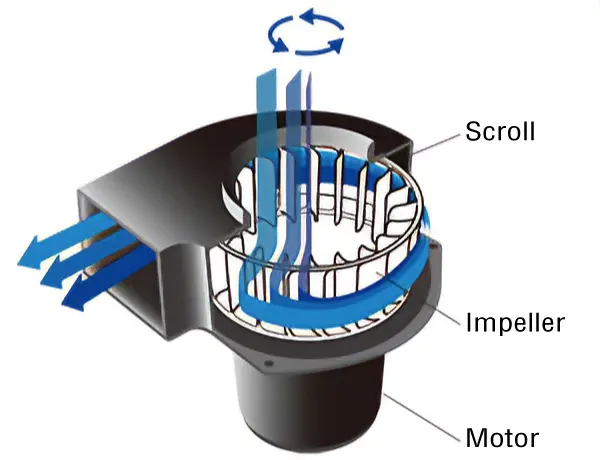

The centrifugal blower generates a swirling flow almost perpendicular to the axis of rotation due to the centrifugal force of the cylindrically arranged impellers.

The swirling flow is rectified in 1 direction by the scroll, which increases the pressure, resulting in a high static pressure.

By squeezing the exhaust outlet of the centrifugal blower and concentrating the airflow in 1 direction, excess batter liquid can be blown away.

Adjust the Air Flow According to the Load

The air flow can be adjusted manually by using the air flow adjustment damper (sold separately).

Easy Installation without the Need for Mounting Brackets

By using through holes and tapped holes in the centrifugal blower body, it can be mounted directly on the equipment.

Lineup of Products That Can be Selected According to the Application

Choose according to the strength of the blow-off and the size of the load.

Variable speed type fans can adjust the air flow with variable resistors (included).

[Lineup List]

| Series | Impeller Diameter | |||||

|---|---|---|---|---|---|---|

| φ50 mm | φ60 mm | φ80 mm | φ100 mm | φ120 mm | φ160 mm | |

|

AC Input MB Series

S Type

|

● | |||||

| ● | ● | ● | ● | ● | ● | |

| ● | ||||||

| ● | ● | ● | ||||