Automating Grease Application With the Small Robots OVR

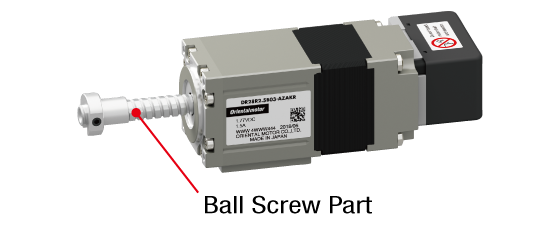

The assembly process for Oriental Motor compact electric cylinders begins with applying grease to the ball screws.

However, since this process was done manually, it required human skill in terms of the amount or position to be applied, etc.

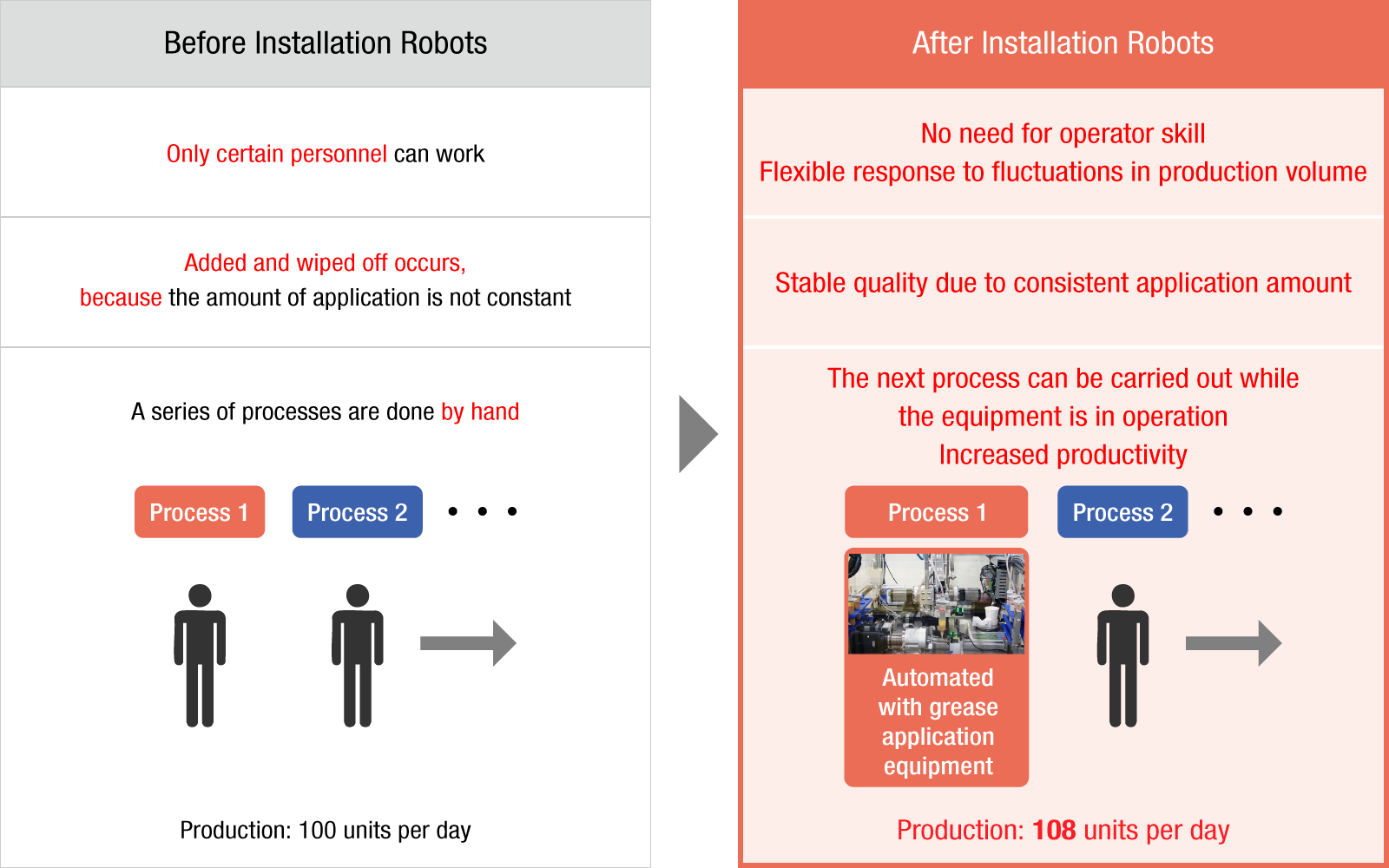

As a result, only certain personnel could work, creating a bottleneck in improving productivity.

Issue

Manual Labor Does Not Improve Productivity and Quality is Difficult to Stabilize

Conventional Problems

- The amount of grease application or the position to apply it, etc. requires human skill

- Only certain personnel could work, which does not improve productivity

- Added and wiped off occurs, because the amount of application is not constant

Solution

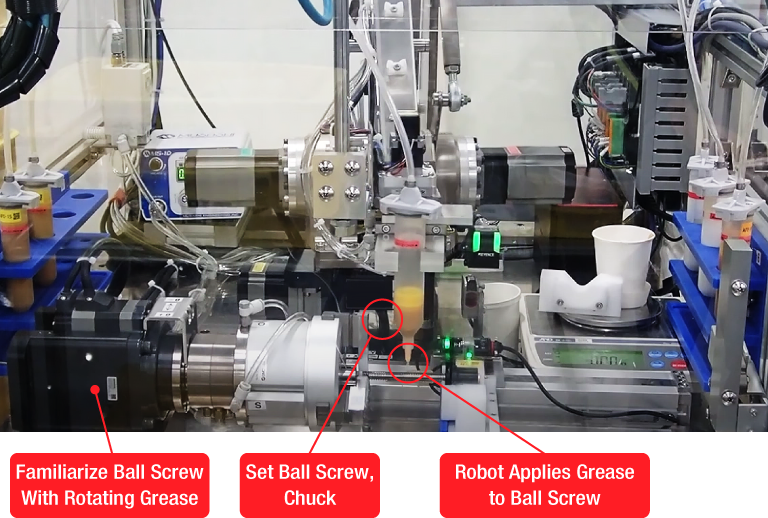

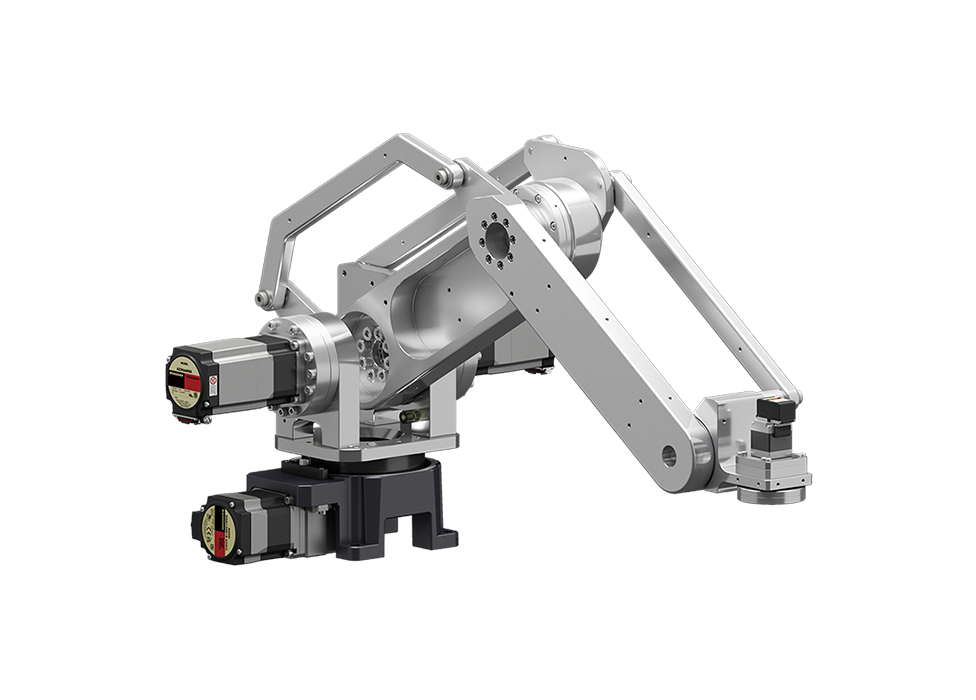

Automated Grease Application Using Small Robot Arm

- Manufacture and install a grease application equipment using Small Robots OVR 4-axis articulated robot, and robot controller MRC01

- Achieved a constant application amount by mechanizing the grease application that was done manually

- The process of applying grease to the ball screw mechanized using the hollow rotary actuator DGII Series, the electric linear slide EZS Series for clean room use

- Equipment

- Grease application equipment

- Application

- Applying grease to the ball screw

- Adopted Products

- Small Robots OVR 4-axis articulated robot

Robot controller MRC01

Hollow rotary actuator DGII Series

Electric linear slide EZS Series for clean room use

- Equipment Specifications

-

Dimensions (mm) W 800 × D 1200 × H 1600 Cycle Time Less than 100 sec. Main Power Supply 100 VAC Target Load Length: 67~181 mm Diameter: 4~14 mm

Key Adoption Points

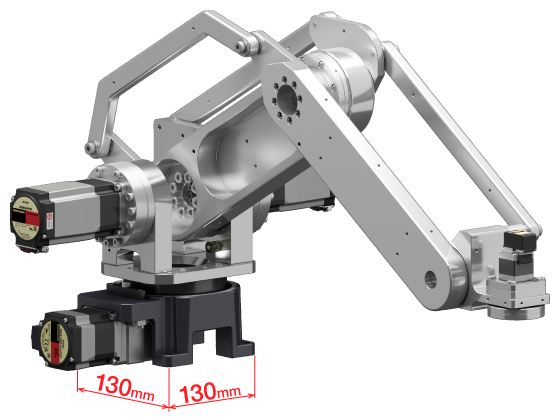

Space Saving

Since different products use different grease, the facility requires space to install multiple dispensers.

For this reason, considered the articulated robot rather than cartesian axis such as linear slide/cylinders.

The Small Robots OVR 4-axis articulated robot decided key points for using because it has space saving footprint of 130 mm × 130 mm and thus can secure a large work space, and is inexpensive.

This allows multi-product production can be enabling dispenser auto-change (setup) because multiple dispensers to be installed in a small space within the facility.

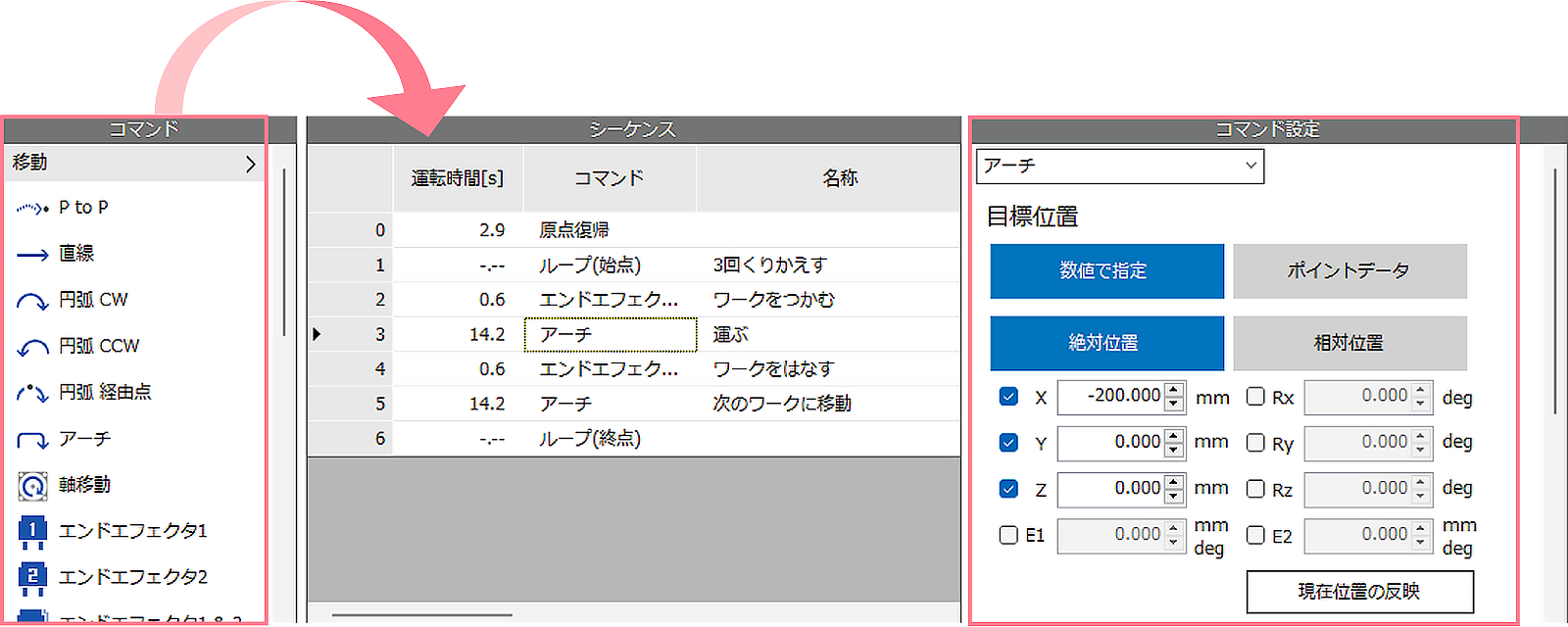

Easy Programming

No ladder knowledge required. Program operates by selecting items

In terms of control, creating a ladder program is usually difficult and requires a high level of skill when controlling multiple axes of the motor with a PLC.

Therefore, decided to also adopt the MRC01 robot controller, which makes programming easy.

Reducing the Burden and Time for Start-up

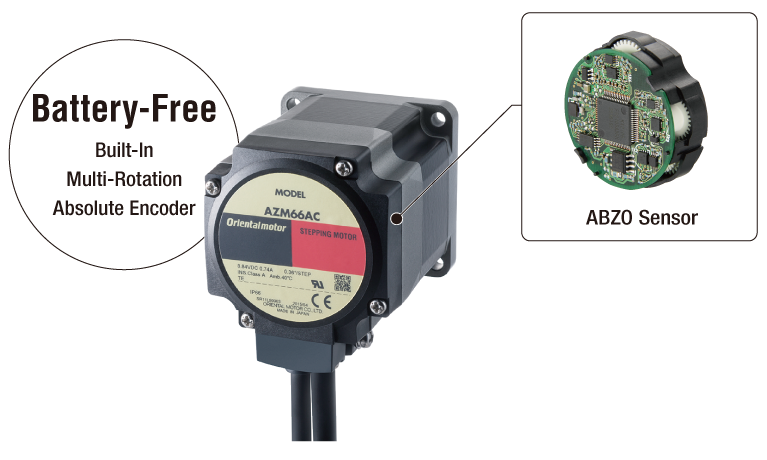

Actuators equipped with the AZ series built-in battery-free absolute encoder was used for rotational drive and linear drive around the robot.

Because the motor is same as the AZ series, the wiring and control can be unified, and burden and time for start-up have been reduced.

Introduction Effect

Adopted Products

Small Robots OVR 4-Axis Articulated Robot

OVR4068K5-V

- Parallel link mechanism

- Horizontally level at all times to allow for stable transport of components

- Maximum Payload: 5 kg

- Maximum reach (horizontal) 480/680/880 mm

- Drive Motor: AZ Series (DC input) equipped with battery-free built-in absolute encoder

Robot Controller MRC01

- Easy introduction and control of robots

- Easy setup with programming software

- Articulated/SCARA, cartesian robot control possible

Hollow Rotary Actuator

DGII Series

- Integrated hollow table and closed loop stepper motor

- Product equipped with a servo motor is also available

- Frame size 60~200 mm, diameter of hollow section φ20~100 mm

- High-strength, high accuracy positioning

Electric linear slide EZS Series for clean room use

- Ball screw drive

- Closed loop stepper motor equipped

- Stroke 50~850 mm

- Compact, high rigidity, for clean room use