Supporting In-house Robot Production With Our Products and Services

Publishing in-house robot case studies, and releasing a robot controller

The automation of transport and simple tasks is highly effective, drawing interest from many manufacturing industries. However, it is also true that some issues have become apparent when it comes to introducing robots, such as the high initial investment and the inability to install them in confined spaces. This is where the in-house production of robots is attracting attention. Oriental Motor has published examples of its in-house robot production, launched a robot controller, and provides control software free of charge. We asked Hiroshi YAMAKOSHI, Manager of the Product Planning Section, Product Planning Department, Sales Division, for an overview.

The Growth of In-house Production of "Robots Tailored to the Actual Conditions of the Company"

Currently, manufacturing sites are increasingly seeing the automation of transport and other simple tasks previously performed by humans. The introduction of transport and work robots is highly effective, and has attracted much attention from companies, but as their introduction progresses, challenges are also increasingly apparent.

For example, AMR (Autonomous Mobile Robots) are generally expensive, costing about 1.5 million JPY per unit, while highly sophisticated work robots are more than 3 million JPY. Furthermore, actual implementation requires system integration by an SIer, so initial investment ends up exceeding 10 million JPY. "Due to the costs involved, some companies wonder if it makes sense to reduce manpower and invest in robots, or if it would be cheaper for people to do the work. The reality is that many companies are hesitant because they fear they may not be able to recoup their investment," says Yamakoshi.

In the case of an articulated robot that takes over simple tasks previously performed by humans, if a generic product is introduced, the higher-level system, line configuration, and space must be reconfigured to accommodate the robot. There are no robots available for automation in very narrow spaces, making installation impossible, but even if there were, these may be overengineered. In both cases, it seems that automation is often deferred because it is not worth the cost and effort.

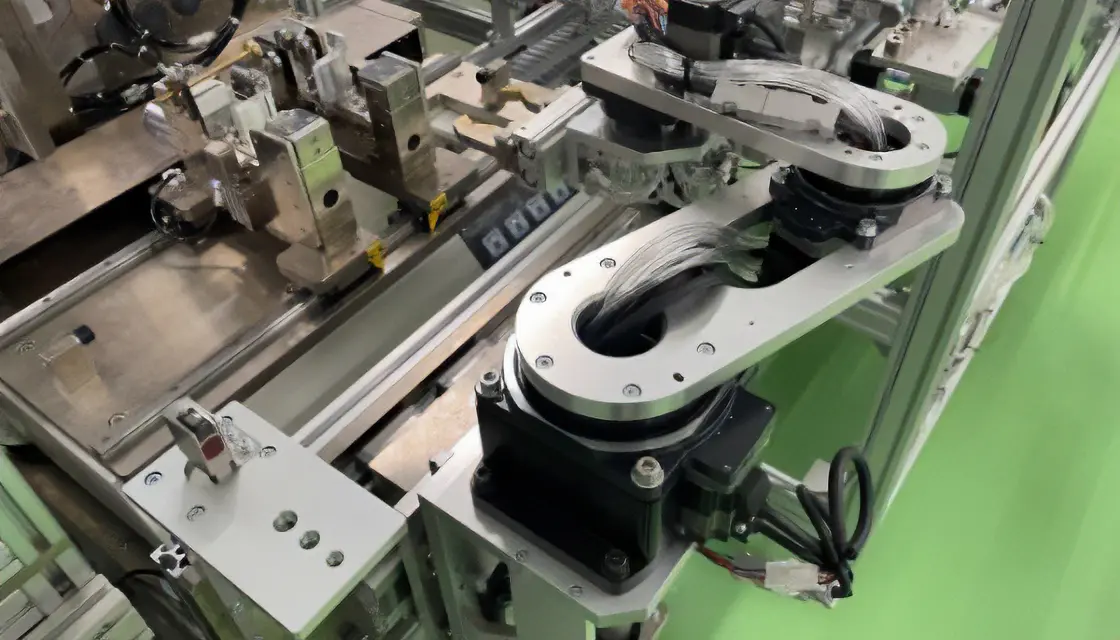

This is where the in-house production of robots tailored to the actual conditions of the company (in-house production) is attracting attention. Increasingly, efforts are being made to build AGVs (Automated Guided Vehicles) in-house, mount work units (robots) such as loader/unloader conveyors, horizontal SCARA, gantries, and vertical articulated units on top of purchased AGVs/AMRs, or build robots for confined spaces in-house. "At the exhibition, the fact that we build our own motors and drivers to operate our robots drew a lot of attention, and we received many inquiries about how to manufacture them in-house. It is cheaper to manufacture in-house, and there is also the advantage of being able to perform maintenance in-house," says Yamakoshi.

On the other hand, we hear from customers that even if they are able to create a mechanical robot, controlling and programming it for actual operation is difficult, making them hesitant to pursue in-house production. It was a real challenge finding a way to meet our customers’ needs to somehow realize in-house robot production.

Hiroshi YAMAKOSHI, Manager, Product Planning Section, Product Planning Department, Sales Division

Providing Everything from Motors to Robot Controllers and Programming Software

The first important step in in-house robot production is motor selection. To this end, Oriental Motor offers a complete lineup of control motors, with a focus on the αSTEP AZ Series equipped with battery-free absolute encoders, gearheads, electric actuators, and more.

Then, to help customers select the most suitable motor, we offer a motor sizing service free of charge as a part of our sales activities, presenting motors that correspond to drivable motor type and required torque. "For example, for an articulated robot, if the customer provides us with information such as arm length and load, we can provide an appropriate motor along with the calculation results," says Yamakoshi.

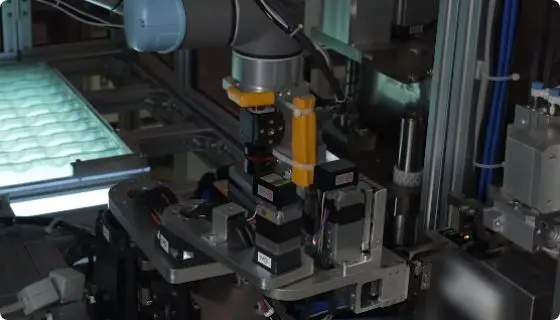

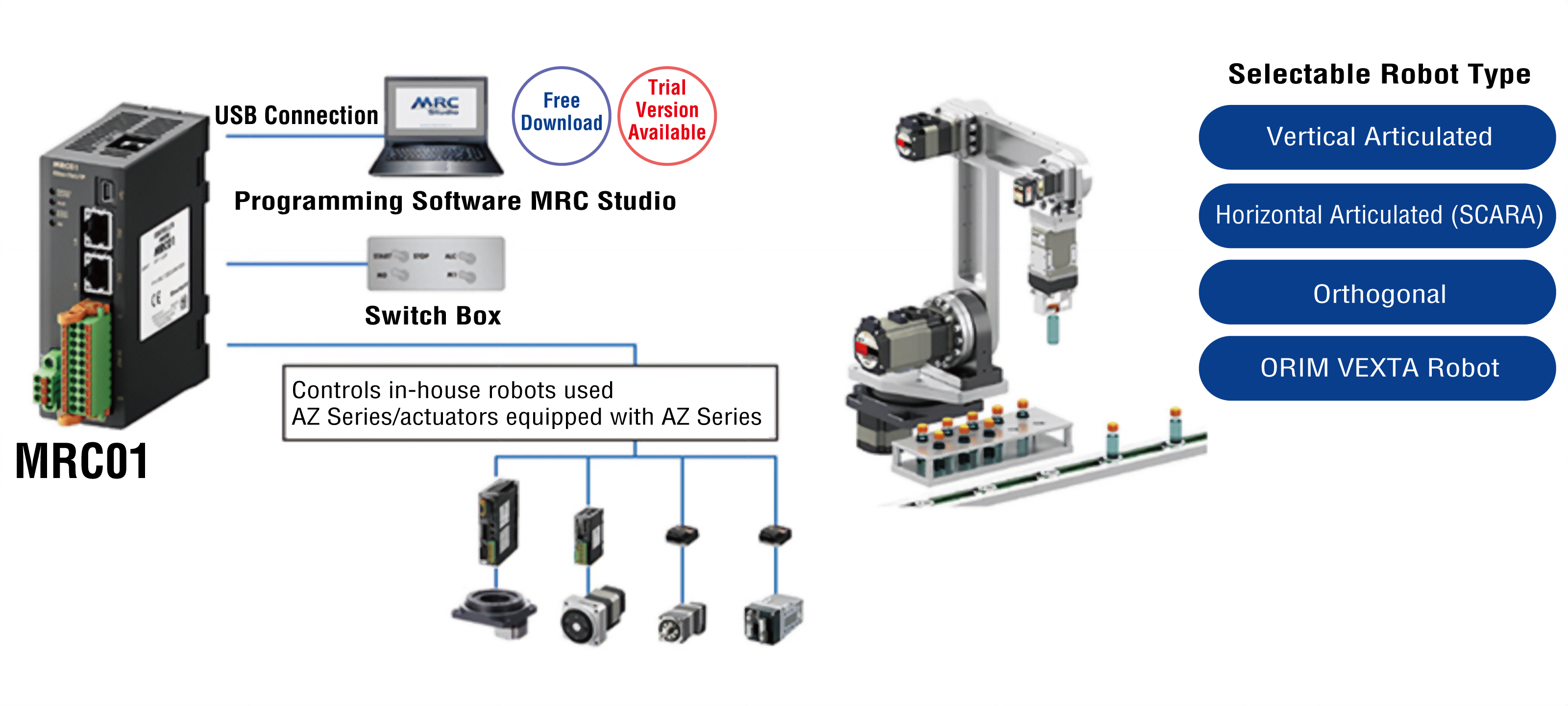

Moreover, although Oriental Motor is a motor manufacturer, to meet customer programming needs, we also offer the MRC01 robot controller with free dedicated configuration and our MRC Studio programming software.

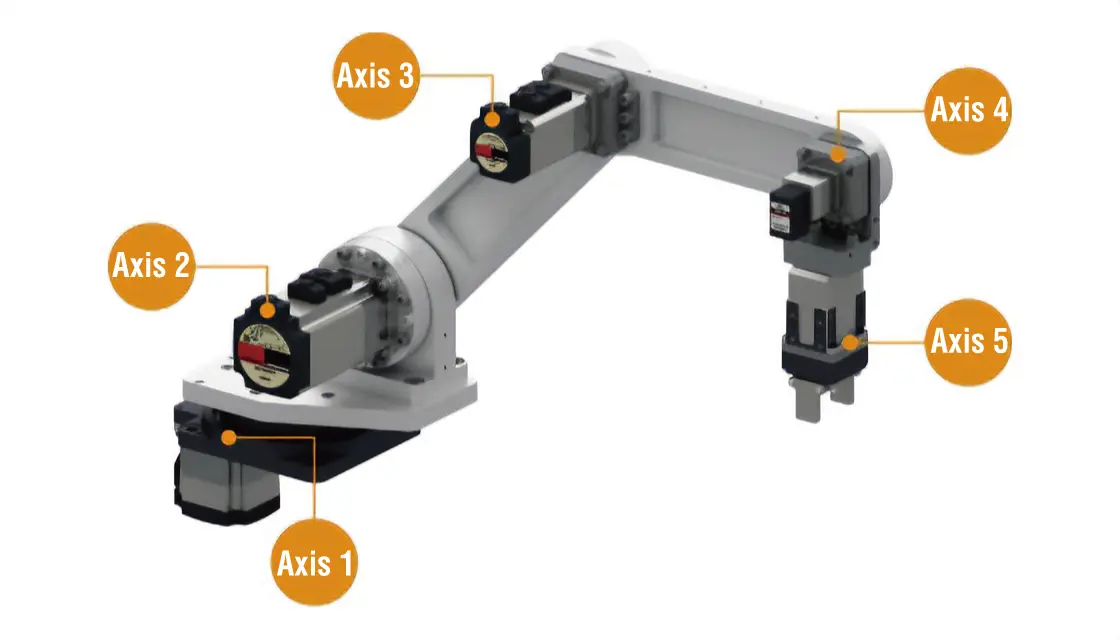

The MRC01 is a robot controller that allows easy introduction and control of in-house robots in three steps: initial settings, operational programming, and operational confirmation (see figure).

By simply connecting MRC01 under the PLC, additional in-house robots can be introduced without significantly altering the control system of existing equipment. For simple sequences, direct I/O can be used without a host device. It can be connected to AZ Series/AZ Series equppied electric actuators, and the robot type to be controlled can be selected from articulated, horizontal articulated (SCARA), cartesian, and ORIM VEXTA robots manufactured by our affiliated company.

MRC Studio, the dedicated software for configuration and programming, has an easy-to-understand user interface for beginners, allowing configuration and programming in a wizard format with no specialized knowledge needed. It can be downloaded for use free of charge, and has been very well-received for its ease of setup and use," says Yamakoshi. Although it has been less than a year since MRC Studio was launched, some mass production lines have decided to adopt it. A medical device manufacturer evaluated its operability and decided to introduce a Cartesian robot programmed with MRC Studio to transport loads.

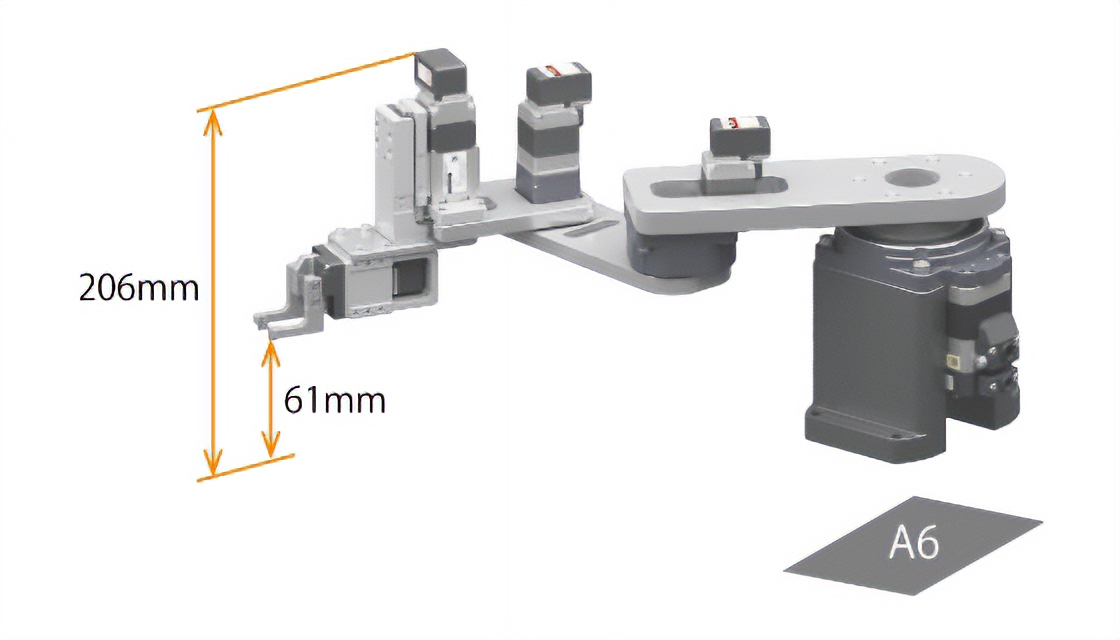

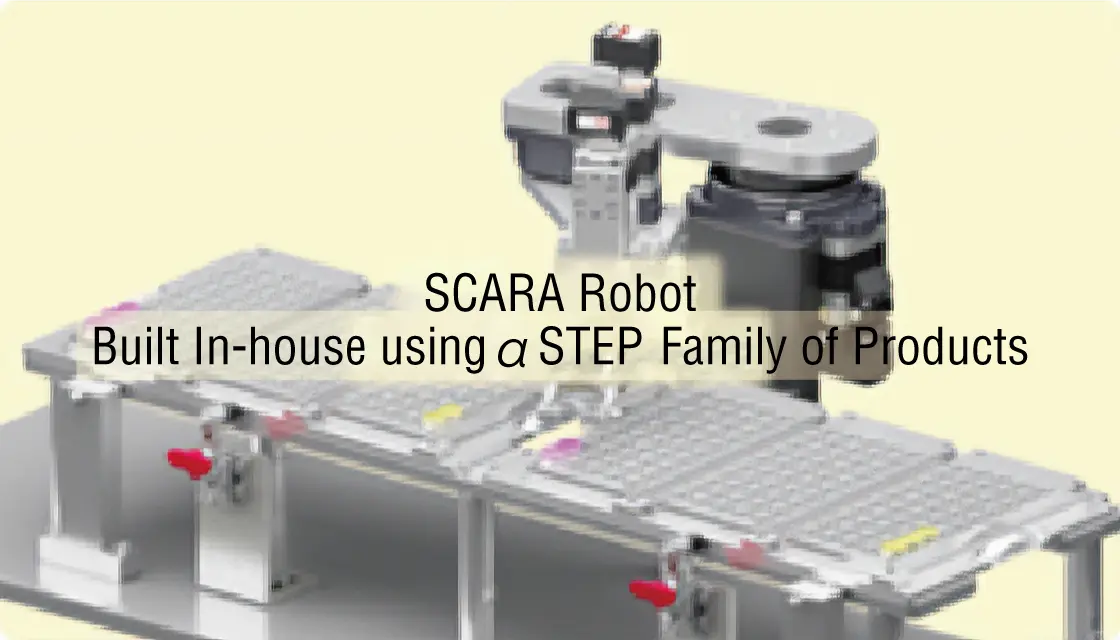

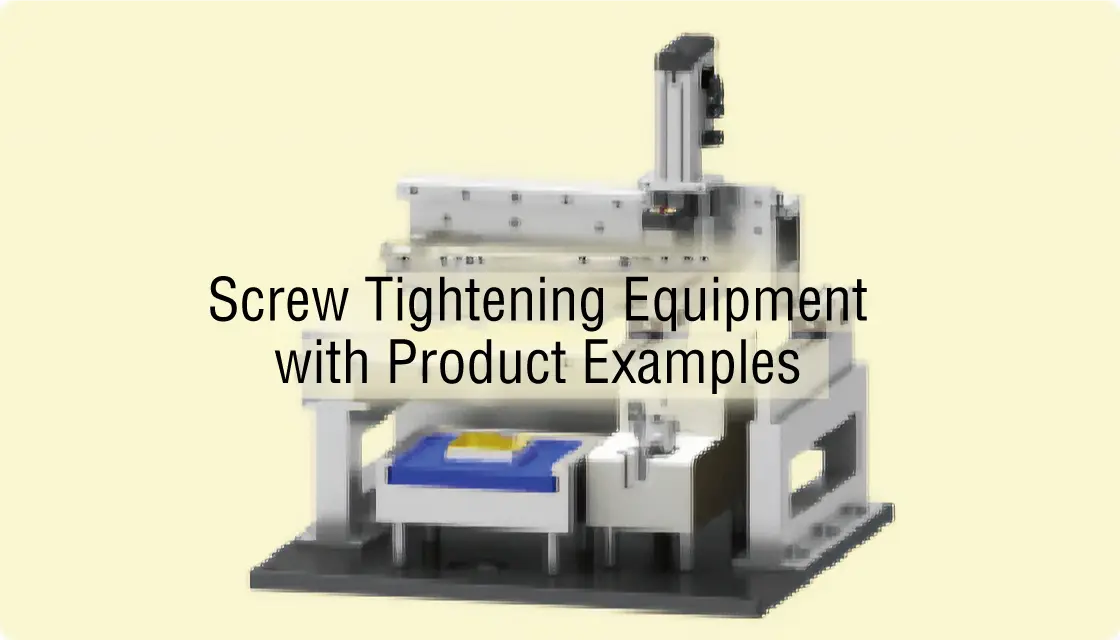

Published Examples of In-House Production of Robots That Can Be Introduced for Less Than 1 Million JPY

Recently, we have been receiving an increasing number of inquiries from customers who have no experience in in-house robot manufacturing, asking for specific details such as feasibility, system configuration, price, and size. Therefore, Oriental Motor has published on its website case studies of in-house production being used at actual manufacturing sites, such as SCARA robots (horizontal articulated robots) for inter-process transfer, AGVs, screw tightening equipment, load processing equipment (cartesian robots and elevating/lowering and swivelings), load elevating and lowering equipment, and multi-product parts feeder. We also include their structure and system configurations, along with commentary on points for product selection. "All are robots that can be introduced for under 1 million JPY, including electrical components, and we have disclosed the drawings, system configuration, and costs. Some customers are hesitant to make the initial investment, but with a list price of less than 1 million JPY serving as a guideline, many think, 'This seems doable!'," says Yamakoshi.

Companies looking to automate simple movements such as transport over short distances between processes at minimal cost are welcome to contact Oriental Motor. We offer products and services that enable the realization of small, easily controllable, in-house robots.

Support for Equipment Design from the Product Selection Stage

- A full-time member of staff will select a motor on your behalf.

- Materials related to equipment specifications and dimensions of our in-house manufactured equipment are available.

For more information, please call or contact us via the web.