Electric Grippers for Automation

The Latest Trends in Industrial Robots

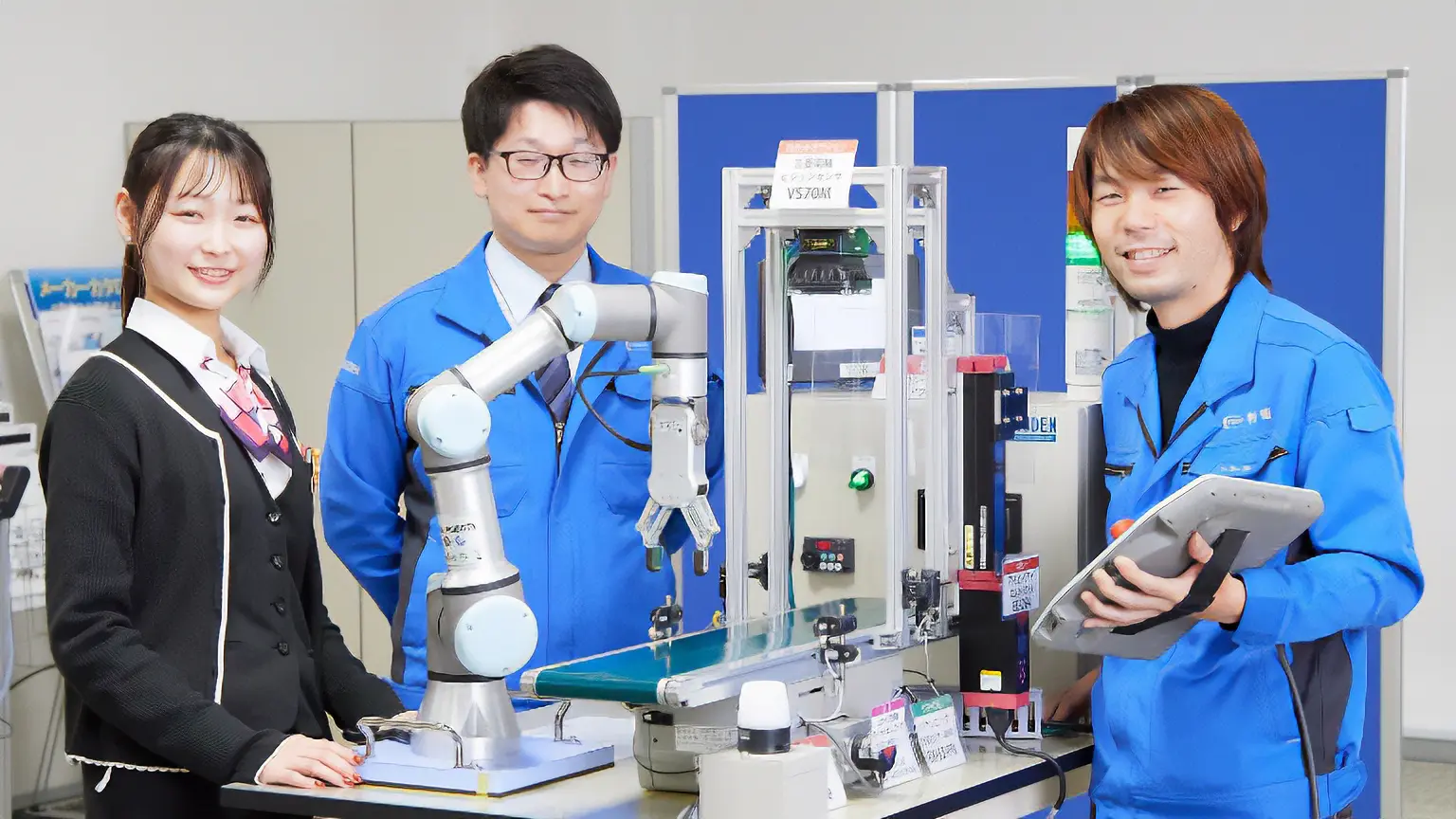

As a system integrator for FA and robots, Tokuden Co., Ltd. supports customers' manufacturing through solution systems, robot systems, and FA trading. They cater to a diverse range of customers, including the automotive, textile, pharmaceutical, and food industries, primarily in Shizuoka Prefecture. This time, we heard about examples of electric grippers previously adopted by Tokuden, the latest trends in industrial robots, and electric grippers for automation.

Chapter 1. Adoption Examples of Electric Gripper EH Series

We confirm the shape and machining accuracy of the customer's target workpiece and suggest an appropriate gripper.

First, we spoke with Director Ota of the Fuji Sales Office at Tokuden Co., Ltd., who has been in charge of customer relations regarding the past use cases of Oriental Motor's Electric Gripper EH Series.

We have heard that your customers have used the Electric Gripper EH Series before. Could you please tell me the background of that occasion?

Ota:The product was adopted for use in automated production facilities operating in the factory. It is intended for gently and slowly grasping lightweight work. They also considered air grippers; however, there was a possibility of causing damage to the workpiece with air gripping, and conversely, there was a risk of dropping the workpiece when reducing the air pressure. The electric gripper is capable of providing a stable gripping force, and it was effectively used for delicate gripping, such as in this case. Additionally, the EH series is small and lightweight, without being affected by constraints on installation space within the equipment. There is also a two-axis gripping mechanism within the same device, contributing to increased productivity.

Customers say it kills two birds with one stone, and the equipment is currently operating stably.

I believe there might be similar demands for gripping applications from other customers. Is there a difference in demand between air and electric grippers?

Ota:In my experience, it's about a 50-50 split in demand. Air grippers are suitable for many applications where simplicity and low cost are key factors. In the event of an air gripper failure, some customers may have maintenance parts on hand and can replace them quickly. For electric grippers, the key point is that adjustment of gripping force is often necessary. For precision products, any scratches on the workpiece can lead to customer complaints. We confirm the shape and precision of the customer's target workpieces and propose suitable grippers accordingly.

Chapter 2. The Latest Trends in Industrial Robots

The number of customers who actively gather information themselves is increasing, and there is a growing demand for proposals.

Next, we interviewed three individuals from Tokuden Co., Ltd. to gather information on the latest trends in industrial robots.

There is a growing interest in robots from the standpoint of labor-saving and efficiency. How have actual inquiries been?

Kameyama: Inquiries related to robots have been increasing overall. Recently, there have been requests not only to entrust the overall system construction to system integrators but also demands that involve the education of the staff (people) handling the system. After the system is implemented, customers need to handle it themselves. Therefore, there are requests that also include the aspect of education.

Have you noticed any changes in customer demand or usage patterns for industrial robots?

Suzuki:It varies depending on the size of the company. For large enterprises, it seems that the adoption of robots is accelerating. In production sites with multiple product varieties, modifications to the equipment (changeovers) are required for each product type. By introducing robots into such scenarios, it becomes possible to achieve cost savings as programming changes alone can be made without the need for frequent modifications to the equipment. It seems there is a desire to leverage robots in such aspects, isn't there? Furthermore, there are customers who actively externally promote their efforts in adopting robots as a proactive corporate stance. On the other hand, when it comes to small and medium-sized customers, not as many express a strong desire to introduce robots. In most cases, introduction is initiated following proposals from our company.

In what situations do you propose robots to small and medium-sized customers?

Suzuki:It often happens during the launch of new production lines. When using right-angle shafts, a robot is basically limited to performing only one task, so there are often proposals to create robots that can do various things.

Kameyama: Recently, it has become more common for customers to gather information themselves from websites and the like, and there has been an increase in cases where they ask if certain things can be done. I believe we need to make proposals taking into account the latest technological trends.

Chapter 3. Support for the Implementation of Robotic Systems

In June 2020, Robot Lab opened as a showroom that also enables test operations.

Can you tell us about support for the introduction of robots in your company?

Suzuki:Broadly speaking, there are two main aspects. There are two types of cases: the entire system is contracted, or only the robot itself is sold. Furthermore, regarding system construction, we listen to the customer's requirements, formulate ideas from scratch, and then make a proposal.

Kameyama:Customers purchasing robots as standalone units have different objectives between large enterprises and small to medium-sized enterprises. In the case of large enterprise customers, there are often instances where they are challenging new ways of utilization. For example, they may want to explore collaborative usage by integrating a conveying robot with a collaborative robot. Small and medium-sized customers often purchase our products in order to strengthen their own technical capabilities, so they expect after-sales support from us. The system is launched by the customer, and we are involved in providing advice on how to use the robots.

In June 2020, Robot Lab was opened. Could you please provide information on the mainly what types of customers visit?

Kurihara:We have many customers who are not very familiar with robots, and many who have never had the opportunity to interact with actual robots. For visited customers, I provide a comprehensive explanation, inquire about their interests and what they would like to do with robots, and then coordinate internally to address their needs.

I understand that at Robot Lab, you also conduct tests utilizing actual robots.

Kameyama:We conduct tests using the hands available in our company. We have prepared several suction hands, and visitors can see how they can grasp objects using these hands. The goal is to help visitors visualize specific usage scenarios, such as whether it's possible to suction oily workpieces.

Chapter 4. Trends and Demand for Robot End Effectors.

Compatibility and connectivity with accessories are also key points in the selection process.

When proposing robots to customers, what are the key points in the selection process?

Suzuki:If the customer already has robots in use, we propose robots from the same manufacturer in consideration of maintenance procedures. We also consider whether the robot is suitable for the application and take into account compatibility with accessories, among other factors.

Tell us about the selection of end effectors.

Suzuki:It's like searching for something that is appropriate for the workpiece. If there is a request for an airless device, we propose electrically powered options in that case. We also prioritize wiring. Passing wires through the arm can impose limitations on movement, so a design that allows the wires to go through the arm makes it more user-friendly. For collaborative robots, there are hands that can be used simply by connecting to the connector, so we suggest such options as well.

Kameyama: Additionally, we may choose based on the compatibility within the lineup, such as finding one with a suitable opening width. In terms of maintenance, electric hands are perceived to be more labor-intensive. There is an impression that air-based systems cause many temporary production stoppages with air blockages and other issues. However, it can be said that each has its pros and cons.

Suzuki:Regarding the opening and closing, not only the stroke but also the way it opens is important. Even with parallel chucks, the way they grip and the movement of the axis can vary by manufacturer, so these aspects also become key points during the selection process.

How about size and availability?

Suzuki:If there are space issues and we have to go for a small robot, we choose a small and lightweight option. However, if there are no restrictions, we don't pay attention to it. We don't worry about availability when introducing a new robot. This is because robots usually have a lead time of several months, so there is no need for them to be available for immediate delivery. For customers, the concern is indeed whether they can obtain replacement parts quickly in case of breakdowns.

Suzuki: I want a highly durable electric gripper with features such as being waterproof and dustproof. For example, a hand that can retrieve drugs from a freezer case or handle work in environments where corrosive gases are generated – a hand that can serve as a substitute for people. While it may be for special purposes, I think if electric grippers can handle such scenarios, it would broaden the range of proposals we can offer to customers.

Chapter 5. Electric Gripper EH Series for Automation

It excels in size and price, making it an effective proposal.

We have released an end effector called the Electric Gripper EH Series equipped with the αSTEP AZ Series. There is a 2-finger type and a 3-finger type, and one of the features is their small and lightweight design. The gripping force is adjustable, allowing for delicate handling that does not damage the workpiece. We also offer flanges that can be attached to commercially available robots. Could you share your candid thoughts about these products?

Suzuki:Among the electric hands I'm familiar with, they’re quite small. Especially for a three finger electric gripper, I have never seen one of this size. I think there are advantages in terms of size. Also, the rotating motion for gripping is unique. It seems like a gripping method that is not very common among other companies.

Regarding the movement of the three fingers, it is assumed that they will be used to grip cylindrical objects such as test tubes or plastic bottles. Additionally, small and lightweight drivers that support a wide range of interfaces can also be installed near the housing of the electric gripper.

Suzuki:By placing the driver behind the hand, it may be possible to use it with lightweight industrial robots with a portable payload. If you choose the EH series, you will need a bellows cable cover because the cables will run outside the motor. Depending on the usage scenario, the range of cable movement may be limited, so it will be necessary to consider the arrangement of cables.

Kameyama:From a sales perspective, one of the attractions is that it is more cost-effective compared to overseas products. We would like to support certifications from various robot manufacturers and easy connection through plug-and-play. Even considering the additional costs, we believe that we can make proposals that are well worth the price.

Finally, could you please share your future outlook as a system integrator?

Suzuki:Technology continues to evolve every day, so we want to actively incorporate new technologies and make various proposals that contribute to solving our customers' challenges.

Assisting in news gathering

Tokuden Co. Ltd.

Headquarters Location: 9-11-5 Futabacho, Numazu City, Shizuoka Prefecture

URL: https://www.kk-tokuden.co.jp/

[Business Details]

Design, production, and sales of FA (Factory Automation) and automation systems, robot systems, on-site information (IoT) systems, and sales of automatic control equipment

Support for Equipment Design from the Product Selection Stage

- A full-time member of staff will select a motor on your behalf.

- Materials related to equipment specifications and dimensions of our in-house manufactured equipment are available.

For more information, please call or contact us via the web.