Compact Electric Cylinders DRS2 Series

DRSM42-04A2AZAK+AZD-KD

| Product Classification | Product Name | CIF: List Price | FOB: List Price | Shipping Date |

|---|---|---|---|---|

| Actuator | DRSM42-04A2AZAK | MYR 2,508 | MYR 2,212 | 17 Working Days |

| Control Circuit | AZD-KD | MYR 1,937 | MYR 1,485 | 7 Working Days |

Included

- Actuator: None

Control Circuit: Main Power Supply/Electromagnetic Brake Connector (CN1), I/O Signal Connector (CN4)

Specifications

Characteristics

Positioning Distance - Positioning Time

Operating Speed - Load Mass

Operating - Thrust

Dimensions

Actuator

Control Circuit

Connection Cable Set (When Selected)

Flexible Connection Cable Set (When Selected)

Data Download

Other Specifications

Circuit Specifications

| Built-in Controller Type |

Pulse input type with RS-485 communication |

Pulse input type | ||||

|---|---|---|---|---|---|---|

| I/O function | Maximum Input Pulse Frequency | - |

Line driver output from host controller: 1 MHz (at 50 % duty) Open-Collector Output by Host Controller: 250 kHz (at 50 % duty) Negative logic pulse input |

|||

| Number of Positioning Data Sets | 256 points | 256 points*1 | ||||

| Direct Input | 10 points | 6 points | ||||

| Direct Output | 6 points | |||||

| RS-485 communication remote input | 16 points | - | ||||

| RS-485 communication remote output | 16 points | - | ||||

| Setting Tool | Support Software MEXE02 | ○ | ○ | ○ | ||

| Coordinates Management Method | Battery-free Absolute System |

○ | ○ | ○ | ||

| Operation | Positioning Operation |

Product Line | Positioning Operation | ○ | ○*1 | ○*1 |

| Positioning Push-Motion Operation *2 | ○ | ○*1 | ○*1 | |||

| Fastening method | Single-motion Operation | ○ | ○*1 | ○*1 | ||

| Sequential Operation | ○ | ○*1 | ○*1 | |||

| Multistep Speed-Change (Configuration Connection) | ○ | ○*1 | ○*1 | |||

| Sequence control |

Loop Operation (Repeating) | ○ | ○*1 | ○*1 | ||

| Event Jump Operation | ○ | ○*1 | ○*1 | |||

| Continuous Operation | Position Control | ○ | ○*1 | ○*1 | ||

| Speed Control | ○ | ○*1 | ○*1 | |||

| Torque control | ○ | ○*1 | ○*1 | |||

| Pushing*2 | ○ | ○*1 | ○*1 | |||

| Return-To-Home Operation | Return-To-Home Operation | ○ | ○ | ○ | ||

| High-speed return-to-home operation | ○ | ○ | ○ | |||

| JOG Operation | ○ | ○ | ○ | |||

| Monitor/Information | Waveform Monitoring | ○ | ○ | ○ | ||

| Overload Detection | ○ | ○ | ○ | |||

| Overheat Detection (Motor and Driver) |

○ | ○ | ○ | |||

| Position/Speed Information | ○ | ○ | ○ | |||

| Temperature Detection (Motor and Driver) |

○ | ○ | ○ | |||

| Motor Load Factor | ○ | ○ | ○ | |||

| Travel Distance , Cumulative Travel Distance | ○ | ○ | ○ | |||

| Alarm | ○ | ○ | ○ | |||

- *1

- It can be used by setting it up with the MEXE02 support software.

- *2

- Push-motion operation is not available for the geared motor and electric actuator DGII Series.

RS-485 Communication Specifications

| Protocol | Modbus RTU Mode |

|---|---|

| Electrical Characteristics | EIA-485 Compliant, Straight Cable Use twisted-pair cables (TIA/EIA-568B CAT5e or better recommended). The max. total extension length is 50 m.* |

| Mode | Half duplex communication and asynchronous mode (data: 8 bits, stop bit: 1 bit or 2 bits, parity: none, even, or odd) |

| Transmission Rate | 9600 bps, 19200 bps, 38400 bps, 57600 bps, 115200 bps, and 230400 bps are available. |

| Connection Type | Up to 31 units can be connected to a single programmable controller (master device). |

- *If a specific wiring and layout causes the motor cable or power supply cable to generate a noise problem, shield the cable or use ferrite cores.

General Specifications

| Actuator | Driver | ||

|---|---|---|---|

| Thermal Class | 130(B) | - | |

| Insulation Resistance |

100 MΩ or more when a 500 VDC megger is applied between the following places:

|

100 MΩ or more when 500 VDC megger is applied between the following places.

|

|

| Dielectric Strength |

Sufficient to withstand the following for 1 minute:

|

- | |

| Operating Environment (When operating) |

Ambient Temperature | 0~+40 °C (Non-freezing)*2 | 0~+50 °C (Non-freezing) |

| Ambient Humidity | 85 % max. (Non-condensing) | ||

| Atmosphere | No corrosive gases or dust. No exposure to water, oil or other liquids. | ||

| Degree of Protection | IP00 | IP10 | |

| Multi-Rotation Detection Range in Power OFF State | ± 900 revolutions (1,800 revolutions) | ||

- *1

- (Only for types with electromagnetic brake)

- *2

- According to Oriental Motor’s measurement conditions

Note

- Disconnect the motor and driver when measuring insulation resistance or conducting a dielectric strength test.

Also, do not conduct these tests on the ABZO sensor part of the motor.

Travel Direction

At the time of shipment, the travel direction of the ball screw is set as follows.

Standards

Regulations and Standards Materials

Documents about compliance with regulations and standards can be downloaded from the "Data Download" tab on the product details page.

(The types of files available for download vary by product.)

Explanations of the Global Laws, Regulations and Standards can be found here.

Information about our compliance with regulations and standards for each of our product series can be found here.

Hazardous Substances

The product does not contain any substances (10 substances) exceeding the regulation values of the RoHS Directive (2011/65/EU, 2015/863/EU).

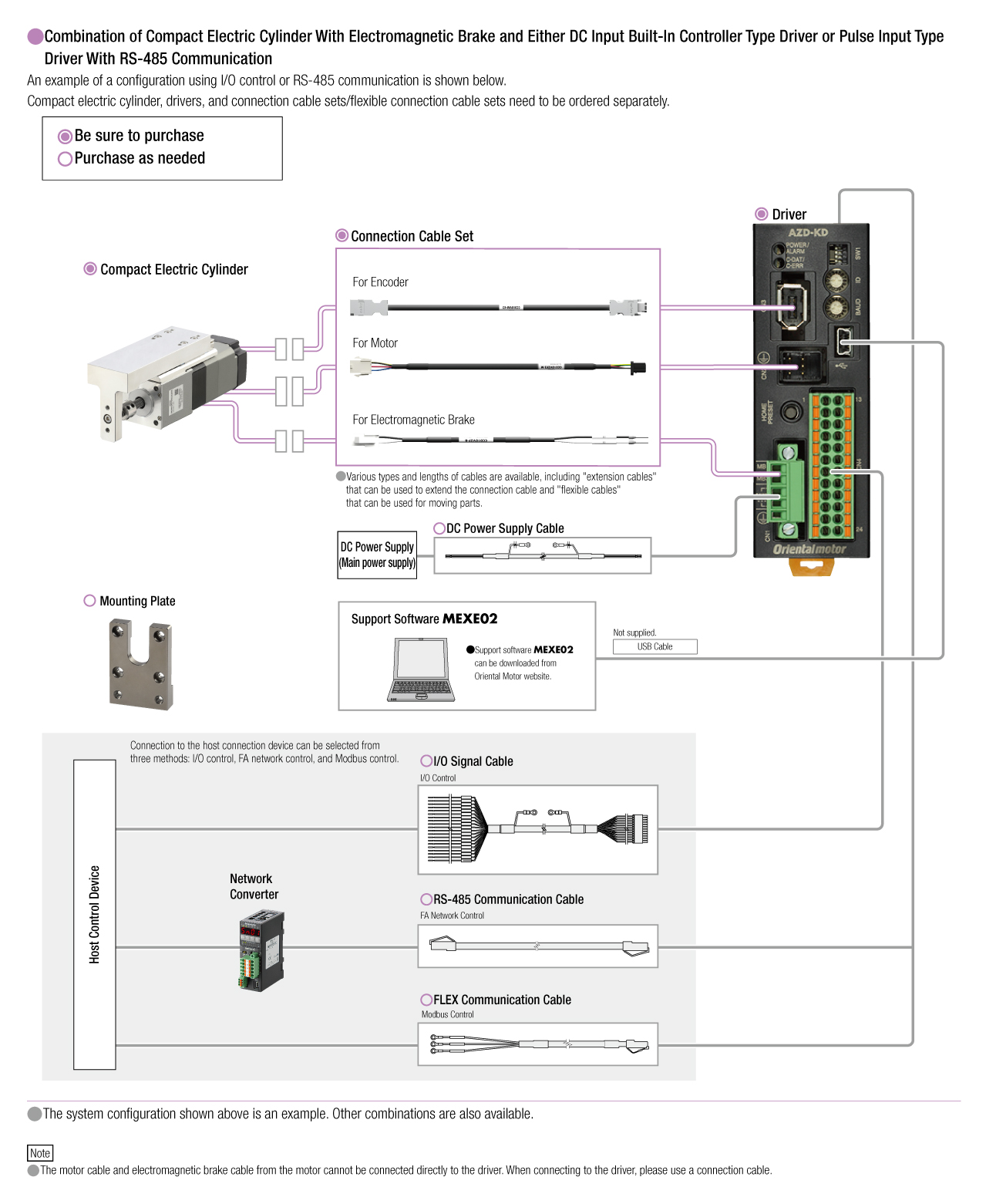

System Configuration

Related Products

Network Converter

| Products | Features | ||

|---|---|---|---|

NETC02-CC

|

Features |

[CC-Link Ver. 2 Compatible] By supporting CC-Link Ver.2, you can simplify the ladder program and shorten the communication time for data sending and receiving. |

|

| Products |

NETC01-CC

|

Features |

[CC-Link Ver.1.1 Compatible] By connecting a network converter, you can complete the wiring process with a single dedicated cable approved for the CC-Link communication protocol. |

| Products |

NETC01-M2

|

Features |

[MECHATROLINK-II Compatible] By connecting a network converter, the wiring process can be completed with a single dedicated cable approved for the MECHATROLINK-II communication protocol. |

| Products |

NETC01-M3

|

Features |

[MECHATROLINK-III Compatible] By connecting a network converter, the wiring process can be completed with a single dedicated cable approved for the MECHATROLINK-III communication protocol. |

| Products |

NETC01-ECT

|

Features |

[EtherCAT Compatible] |