What Motor Should be Used for AGV?

-

Ms. Ori, can I ask you something about AGVs?

-

What's going on?

-

I received an inquiry asking, "What kind of motor should I use for an AGV?" and I was stumped as to where to start...

-

Okay, let’s look at it together.

AGV stands for "Automated Guided Vehicle" and they are driverless transportation vehicles used in the factories. There are 2 types of AGVs: one that transport loads and other that tow vehicle.

There are many ways to guide a vehicle so that it moves automatically. They can move by detecting metal or magnetic tape laid on the floor, but I’ve recently heard of vehicles that use cameras for image recognition or GPS to move automatically. -

Why are people focusing so much on AGVs?

-

The needs for labor-saving methods are increasing to respond to labor shortages and reductions to workloads. Until recently, workers usually distributed and transported parts between production lines. The current trend is to make automated 24-hour production lines and let AGVs handle transportation between processes. In some cases, they are used instead of conveyors in production lines to create layouts with a greater degree of freedom.

-

It seems like AGV will be more common in the future.

So what are the key points when selecting a drive motor? -

First, the power supply specifications. AGVs are self-propelled, so most of them are battery-driven and the most common voltage are 24 VDC and 48 VDC.

-

When it comes to the batteries, I’m worried about running out of power or voltage deterioration.

How should we respond? -

To avoid having an AGV stop in the middle of a run, plants usually create a waiting areas like charging stations and have them stop by periodically to recharge.

-

I’d also be worried about speed loss from lack of power when the voltage drops.

-

That can be detected in advance if the AGV is equipped with a voltage monitoring device or a sensor, or if the drive motor side has a voltage deterioration notification function. I wonder if it would be a good idea to use a motor that could drive to some degree even if the power supply voltage drops a little.

-

I see. So that’s also important point in selection.

-

Next, let's look at the movement of AGV. When they’re moving straight, they need to do it without deviating and when they’re turning, the left and right wheels must be driven by the separate motors to create a different speed.

So what is needed for the motors to move straight? -

If the speed of the left and right wheels needs to be synchronize as much as possible, I think that a motor with less speed fluctuation relative to command would be better.

-

That's right.

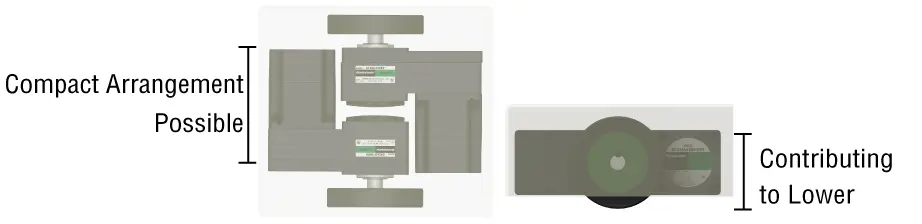

Next is the AGV’s weight and external dimensions. In order to make the vehicle compact or give it low clearance, the motor size must be small as much as possible, the overall width of the vehicle must be short as much as possible, and connection between the motor shaft and vehicle shaft also have to be space saving. -

Based on the previous points, a brushless motor with low speed fluctuation, small size, and high power would be appropriate.

For DC input, I think the BLV Series R Type and BLH Series would be a good candidates.

And if they choose a hollow shaft flat gearhead, they could connect it directly to the vehicle shaft for space savings.● Example of Using a Hollow Shaft Flat Gearhead for AGV

-

By the way, designing an AGV requires a lot of time and work, right? Do you know any products that would make installation easier?

-

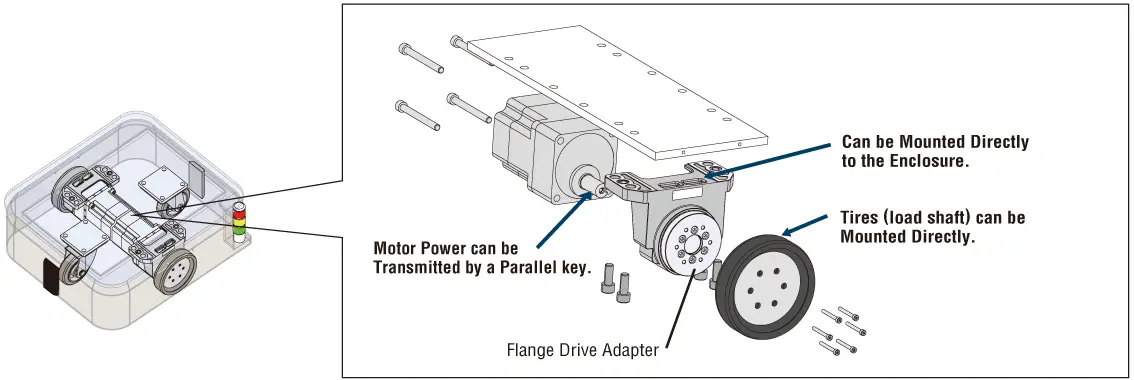

The flange drive adapter (for 100 W output power) with integrated load mounting table!

-

That's right. It can be used in combination with a parallel shaft gearhead.

It makes easy to attach both AGV tire and the enclosure directly.● Example of an AGV With a Parallel Shaft Gearhead and Flange Drive Adapter

-

I'll tell our customer about flange drive adapters!

-

Good idea. I recommend BLH Series for the compact size and BLV Series R Type for the large size. The BLV Series R Type has features that are suitable for AGV, but do you know what they are?

-

If I remember correctly, it can operate across a wide range of voltages. So, it can be driven even if some voltage fluctuation occurs.

● A Wide Range of Allowable Operating Voltage

-

You’ve really been hitting the books! Keep it up.

-

Thank you very much! I will introduce this to the customer as soon as possible.

- Updated with the latest information in April 2022.