What Should Be Noted in Speed Control for Vertical Operation?

-

Ms. Ori! A customer asked us if we have a motor that allows to perform speed control under vertical operation. I've had similar inquiries before, so this time I'll be able to answer with confidence. (Please refer to back numbers for more information.)

-

Oh, you’ve become so reliable! Which product are you introducing?

-

Brushless motors with electromagnetic brake type!

-

Do you remember what you need to be careful when using vertical operation with brushless motors?

-

Umm... I'm sorry. I forgot.

-

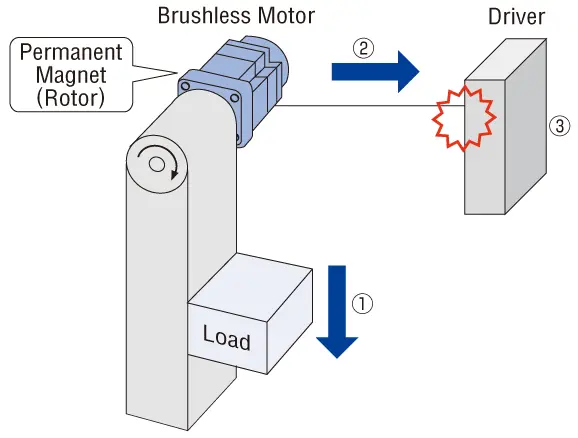

Come on! You need to be careful if the output shaft of the motor is turned by an external force during descent, as the permanent magnet (rotor) will turn the motor into a generator and electricity (regenerative power) will flow to the driver (Figure 1). Then, the driver's protective function activate and an alarm will occur. So you need a "regeneration resistor" to absorb this regenerative power.

Figure 1 An Example of Regenerative Power Generation in a Brushless Motor

- ①

- Gravity lowers the load and the motor shaft is rotated

- ②

- Electricity generated by the motor flows to the driver (regenerative power)

- ③

- Alarm occurs

-

Aside from vertical operation, are there other cases where a regeneration resistor is needed?

-

For example, it may be necessary to stop a large inertial object such as a rotary table because the output shaft of the motor will be rotated.

-

Now I get it! Since it's a vertical operation this time, I'll also introduce the regeneration resistors to the customer!

-

Wait a minute! Are brushless motors the only motors that can perform speed control in vertical operation?

-

Are there other types besides brushless motors?

-

You've still got a lot to learn, Vex. Speed control in vertical operation is possible even with the electromagnetic brake type AC speed control motor (hereinafter referred to as "AC speed control motor") DSC Series.

-

But with the past AC speed control motor, you weren't able to perform speed control via gravitational operation, right?

(Please refer to back numbers for more information.) -

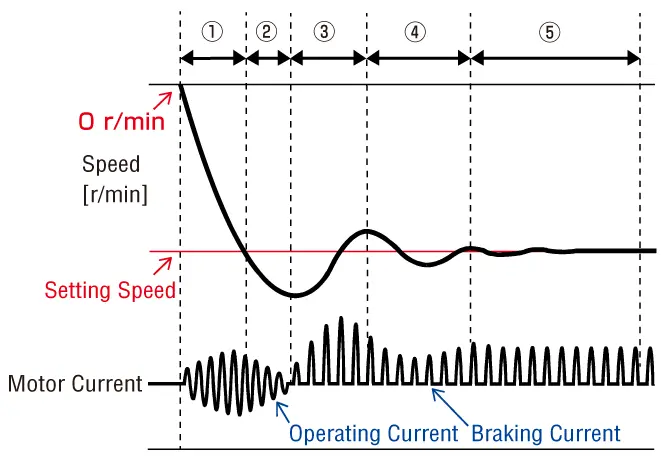

That's right. But the DSC Series controls the rotation speed by applying a braking current whenever it rotates faster than the setting speed.

This control is called "deceleration control."

See Figure 2. The size of the braking current is adjusted according to the rotation speed to get closer to the setting speed.

Incidentally, the DSC Series doesn't need regeneration resistors, even for vertical operation.Figure 2 Example of Start Response During Deceleration Control (Gravitational Direction)

- ① Interval

- Starts operation in the gravitational direction. Acceleration via operating current

- ② Interval

- Reduces the operating current as the setting speed has been exceeded, but is turned by the gravitational load, and so acceleration continues.

- ③ Interval

- Switches to braking current and decelerates.

- ④ Interval

- Adjusts braking current due to excessive deceleration

- ⑤ Interval

- Braking current becomes constant and the equipment operates at the setting speed

-

Why it doesn't need a regeneration resistor?

-

AC motors don't use permanent magnets, so they generate almost no regenerative power.

So there's no need to worry about regenerative power, even during vertical operation. -

If the regeneration resistor is not needed, it means that one of the number of parts can be reduced.

-

That's a very good point. But also tell them that there are limits to the operating cycle and operating duty* when using vertical operation with DSC Series.

-

I got it. I will read the operating manual carefully and make recommendations to the customer.

-

Try introducing them the L Series, which combines the DSC Series motor with a rack-and-pinion mechanism that easily construct a linear motion mechanism!

-

Yes I will!

- * The ratio of operation time when the sum of operation time and stop time are taken as one cycle together.

Related Products

Rack-and-Pinion System L Series

AC Speed Control Motor DSC Series Equipped